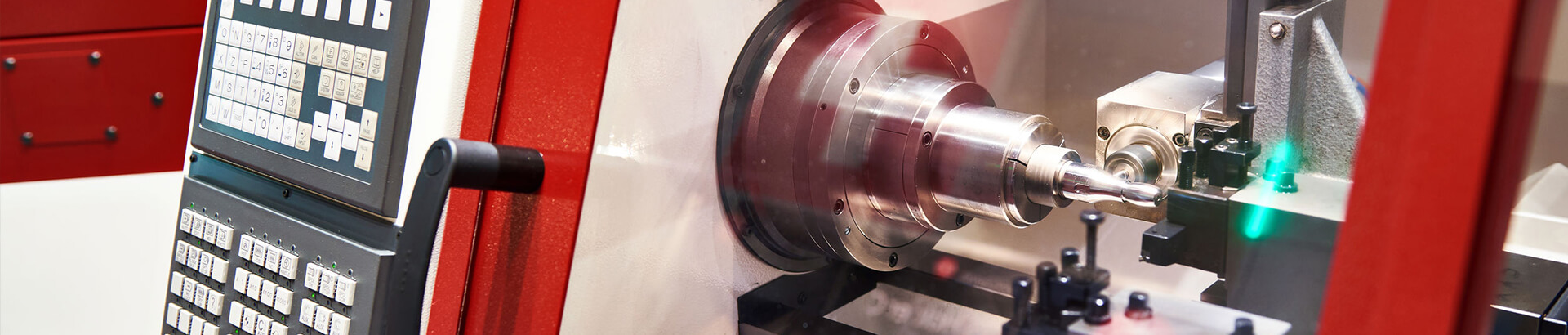

CNC Machining Center (CNC Machining Centre) can be said to be the integration of machine functions. A CNC Machining Center covers a variety of machining capabilities. One-stop manufacturing reduces machine replacement time and improves production efficiency.

The CNC machine center (cnc turning center) is an advanced manufacturing machine tool. Machinery can perform various machining operations. The types and functions of the CNC Machining Center are introduced below.

The CNC machine tool center (machine centre) is an advanced manufacturing machine tool that can perform a variety of machining operations with high precision, high quality, and high surface finish. A CNC machine tool center (CNC turning center) can perform drilling, milling, and lathe operations.

The manufacture of prismatic parts in the industry, such as gearboxes, partitions, frames, covers, etc., requires different types of operations such as milling, boring, drilling, tapping and many other related machining operations. In the past, this production process had to be divided into many working stages, and the operation on different machine tools was able to produce a finished product, which was resulted in a large amount of delivery time and cost. To overcome this problem, a CNC machine tool center was developed. Milling, lathing, and drilling operations on a single machine tool allows one machine to perform a greater variety of machining needs.

The main purpose of the CNC machine center is to reduce production time and advanced mechanisms in the CNC machine center.

- ATC (automatic tool changer)

- APC (automatic pallet changer)

- CNC servo system

- Feedback system

- Re-circulating ball screw and nut

Configuration classification type of CNC machining center:

- Horizontal Machine Center

- Vertical Machine Centers

- Universal Machining Centers

-

Horizontal Machining Center

The machining center(Turning center machine) has a horizontal spindle and the tool is mounted on the spindle of the machine, usually a single spindle machine with an automatic tool changer. The ATC consists of a replaceable magazine that can store multiple tools and hold approximately 16 to 100 tool capacities. To reduce loading and unloading time, an automatic pallet changer (APC) can be installed. The APC consists of six, eight or more pallets, the workpiece can be set in the pallet, and the machine can be programmed to complete the previous pallet. After working, change another new tray. Different programs may be required for different workpieces. Due to the high material removal rate in the process, the cutting tool volume is usually large, so the tool magazine requires a large position on each tool, and the relative weight is getting heavier. Some machine tools also have additional functions for rotating the entire spindle so that the horizontal axis of the spindle becomes vertical, allowing for different operating techniques.

-

Vertical Machining Center

In this type of machine, multiple jobs can be done in a single setup. Most vertical machining centers have three axes, and some have the function of a spindle head that can be rotated on one or two axes. To process the engraving surface, the vertical machining center is most suitable for the mold and mold processing industry. The main types of vertical machining centers are as follows: walking columns, gantry structures, and multi-spindles.

-

Universal Machine Center

The universal machine center is similar to a horizontal machining center, but the spindle shaft can be continuously tilted from a horizontal position to a vertical position under computer control. The universal machine center consists of five or more axes that allow the top surface of the workpiece to be mounted on a horizontal machining center so that different sides of the workpiece can be machined in one unit.

CNC turning center factories(CNC machining centres) in various countries are actively and continuously making breakthroughs in manufacturing capabilities, expecting to develop more precise CNC machining centers.

If you want to receive more instant messages, please follow our Instagram, Facebook, Twitter accounts.

.jpg)

.png)