Computer numerical control (CNC) turning is a subtractive machining process where a cutting tool is placed against a spinning piece to take material off. This is usually done with a CNC lathe or turning center which cuts the material including wood, metal, and plastic. This article will cover the different types of CNC lathes, their components, and which type you could use for your next project.

Ancient History

Lathes (Turning) are one of the oldest types of machines and as we know, are still readily used today. Thousands of years ago, the Egyptians first used lathe technology to make stone housewares. Hundreds of years ago during the Renaissance, lathes were used to make wheels, gears, and parts for mills and pumps.

Nowadays, lathes are still used to make all these things, but also in producing crankshafts, gun barrels, musical instruments, even parts for other precision machines. While 3D printers and the other subtractive CNC machines can also do some pretty amazing things, there’s a lot that only a CNC lathe can do.

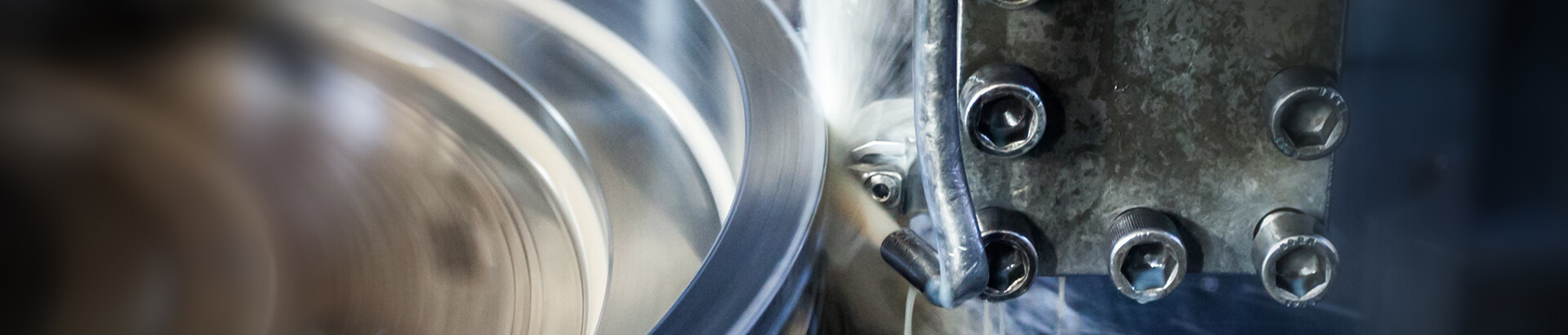

Most subtractive CNC machines such as mills, water jets, and plasma cutters have the workpiece secured to a bed and the cutting done by a spinning tool. To cut, the tool moves across the workpiece or a tool head shoots at it. In contrast, CNC turning reverses that process by rotating the workpiece and cutting away at it (by moving a static cutting bit against the workpiece).

Because of how they operate, CNC mills are primarily used for creating complicated geometries, while CNC lathes are used for creating cylindrical or oblong shapes. A CNC lathe is usually chosen over a CNC mill or 3D printer because of its ability to make multiples of the same part incredibly fast and from one stock piece of material. Check out this mesmerizing video of a CNC lathe in action:

Components of a Lathe (Turning)

While there are several different types of lathes, they all have relatively similar components. Keep in mind that lathes can spin very heavy workpieces at incredible speeds. These machines are built to handle major projects with precision and a small mistake can lead to serious injury or damage.

Let’s take a closer look at each component of a lathe machine:

- CNC control panels are the “brains” where the CNC program is stored. Machinists control the entire lathe from the keys on this panel including starting and stopping a project, moving the axis, and entering new programs.

- Headstocks function as a holding device for the other components of the lathe, including the gear chain, spindle, and driving pulley.

- Tailstocks, though not always used, are a non-rotating center mount used for boring and located opposite of the headstock.

- Spindles are the rotating axis of the machine with a shaft at its heart. Both the headstock and tailstock can have one.

- Chucks are responsible for gripping the component that is to be machined. Chucks can have a different number of jaws for holding the workpiece.

- Beds are the base of the machine and used for the sliding action. The bed can sometimes be extended for larger workpieces or function as a conveyor belt.

- Cutting tools are small bits that remove material in different ways depending on the size and shape of the tool. (Regular drill bits are usually separated from this classification.)

- Tool turrets are the tool carrier for the machine. The shape and the size of the turret are determined by the number of tools that’ll be mounted on them.

- Carriages hold the cutting tool longitudinally to the workpiece for turning, or perpendicularly for facing.

- Foot pedals are used to open or close the chuck or tailstock.

Though lathes are relatively simplistic in their design, they’re hard to master. Understanding the components and how they work individually is the best way to get started with a CNC lathe. Now that we know more about the different parts of the machine, let’s take a look at a few different types of lathes and when you might use each one.

Types of Lathes

There are several different types of lathes out there and each is suited for various kinds of projects. The primary difference between a CNC and a conventional lathe is that a conventional lathe is usually restricted to two axes for tooling, while a CNC lathe can have up to six machining axes and even milling tool options as well.

- Horizontal CNC lathes are one of the most commonly used machines and have all the capabilities of a conventional lathe except they’re controlled by a computer and primarily used for turning and boring.

- Vertical CNC lathes hold the workpiece from the bottom (instead of the side grip is horizontal) and spin it like a top. This is good for workshops with space constraints and when working on particularly stout, heavy workpieces.

- Horizontal turning centers are enclosed CNC lathes that integrate milling and drilling capabilities. A turning center can also include a traveling tool turret, more tooling axes, coolant flooding, a tailstock that is separated from the carriage, and sometimes a conveyor belt.

- Vertical turning centers are a combination of a horizontal turning center and a CNC mill.

While there are many more types of conventional lathes out there, the above four are the primary styles of CNC lathes. Now, let’s look at all the ways they can turn.

Alternatives

Wanting to do some turning but can’t get access to a CNC lathe? Actually, turning technically doesn’t need to be done with a lathe; it can be done with a mill or, more commonly, with a drill press. All that’s required is a chuck that can properly hold the workpiece and some sort of carriage that moves the cutting tool against the component.

If you do happen to try retrofitting your drill press and turning it into a vertical lathe, it’s best to stick with woodturning. That’s because drill presses don’t have the required speed or torque to machine metal the way a lathe does. Whatever you try, always remember to be safe and wear the proper PPE when working with these machines!

.png)