The CNC machining industry has seen amazing developments and innovations since the incorporation of computer programming into machining operations. CNC machining is a highly competitive industry, and among the multitude of companies striving to excel in this field, Chevalier Machinery Inc. has grown to be a leading manufacturer of CNC high-precision surface and form grinders, machining centers, turret milling machines, and multi-function lathes.

Chevalier Design and Smart Manufacturing Solutions

Decades of Expertise and Innovation

Chevalier Smart Manufacturing Solutions

Chevalier Machinery Inc. excels in designing and manufacturing CNC machines which incorporate Chevalier’s innovative Smart Manufacturing Solutions. By introducing cutting-edge smart technologies like SMART iControl, Smart iSurface Control, and the iMachine Communications System™ (iMCS), they have revolutionized CNC manufacturing processes.

SMART iControl

The introduction of Chevalier’s Next-Generation SMART iControl revolutionizes CNC machining. This powerful computing system enhances the Human-Machine Interface (HMI) for better accuracy, data analysis, and connectivity for remote monitoring and production optimization. Users no longer need to write complicated programs or memorize detailed variables, as simplified programming interfaces empower users to tackle complex machining tasks with ease.

iSurface Control

The PC-based iSurface control, equipped with high-response AC servo motors and a variable frequency drive system, ensure improved accuracy and efficiency.

Built-in features like the acceleration gauge and spindle load detection further enhance performance and reliability. The acceleration gauge monitors the grinding wheel's balance at all times. If the wheel becomes unbalanced, the operator will be notified to rebalance it.

The variable frequency drive system automatically adjusts the grinding wheel’s linear speed.

A magnetic encoder accurately detects spindle load and controls the spindle cutting load.

iMachine Communications System™ (iMCS)

Chevalier's exclusive intelligent Machine Communications System™ (iMCS) is a comprehensive remote monitoring system that connects clients with real-time performance data, remote machine monitoring, alarm history, maintenance updates, and overall equipment effectiveness (OEE) analysis, fostering greater efficiency and productivity.

iMCS software is user friendly, IoT ready and specifically designed for an end-user’s analytic needs. This level of monitoring fosters a greater understanding of production assessment that leads to streamlining and maintaining operations for greater efficiency and productivity.

iMCS Features and Benefits

-Machine status: Monitoring of machine condition and real-time machine data

-Utilization: Statistical analysis of all machine conditions

-Program transfer: Transfer of files seamlessly between CNC controls and management center

-Diagnosis: Assessment of machine system and components through on-line system diagnostics

-Maintenance: Preprogrammed service and maintenance recommendations

-Production: Real-time production management with data collection statistics

All Chevalier machines function with iBOX connections. A machine’s sensors send signals regarding temperature or vibration information directly to the iBOX for data collection. After data analysis, the message is transferred back to the machine’s CNC control.

CNC Machining Tools with Integrated Technology

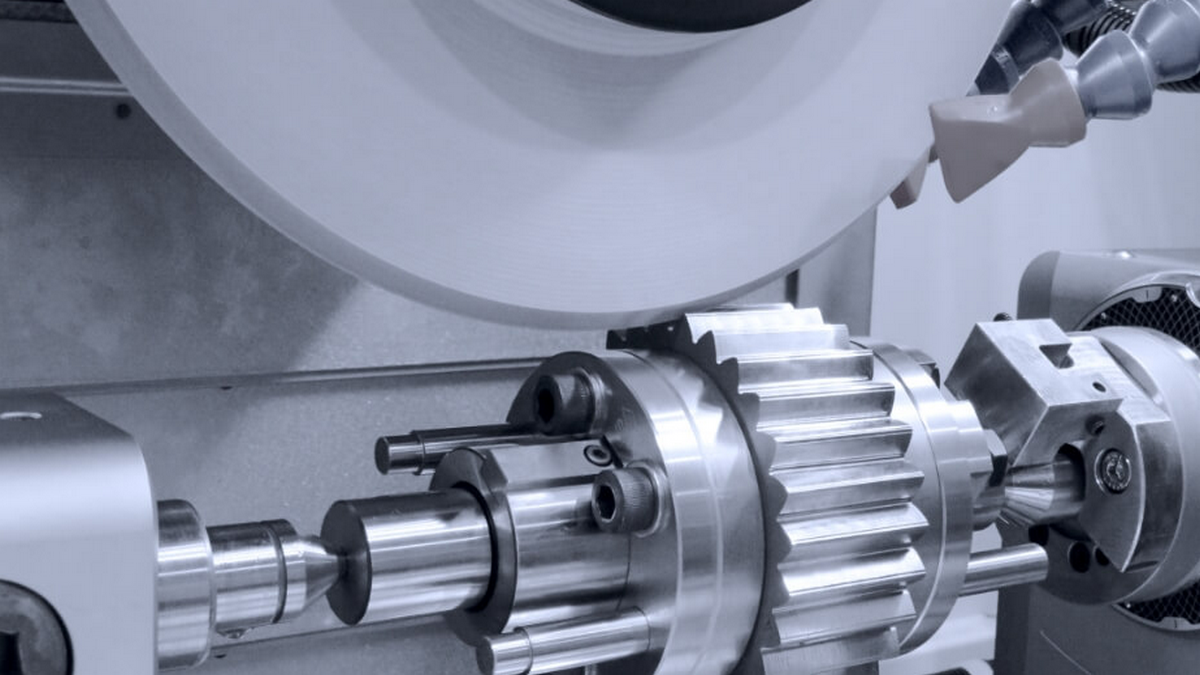

Whether you need Double-Sided Fine Grinders for intricate work or 5-axis Vertical Machining Centers for complex machining tasks, Chevalier Machinery Inc. offers a comprehensive range of Surface Grinders, Machining Centers, and Lathes suitable for various industries.

Surface Grinders

Essential for precision grinding of surfaces, achieving fine finishes and tight tolerances required in industries like aerospace, automotive, and medical equipment manufacturing.

Chevalier offers a wide range of CNC Surface Grinders, Vertical Grinding Centers, Double-Sided Fine Grinders, High Precision Surface and Form Grinders, CNC Rotary Surface Grinders, and Double Column Grinders.

In all Chevalier grinders, in-machine dynamic balancing reduces grinding wheel vibration and eliminates workpiece surface ripple to improve grinding quality. Variable-speed spindles combined with an automatic dressing function provide constant surface speed regardless of the grinding wheel’s changing diameter.

Chevalier’s Smart Grinding Path technology greatly enhances the intelligent grinding path. This smart grinding path automatically minimizes air cutting strokes and improve overall processing efficiency.

Machining Centers

Machining centers, especially multi-axis ones like Chevalier's UNi5X-400, offer versatility in complex milling, drilling, and tapping operations. Chevalier's 5-axis Vertical Machining Centers and Turret Milling Machines are powerful, reliable, and capable of handling complex operations. They also offer fast movement for greater efficiency, meeting the needs of large quantity machining with shorter cycling times.

Lathes: Chevalier's Vertical Turning Lathes and Multi-Function Flat Lathes integrate automation and cell manufacturing for rapid automated production. These lathes are widely utilized in the automotive parts, engines, and compressor industries due to their simplified fixture design, which is excellent for turning irregularly shaped workpieces. They are perfect for heavy-duty turning, milling, boring, grinding, drilling, and thread-cutting applications.

Integrated Machining Capacity

-Aluminum Wheel Production Line

Chevalier has extensive experience in designing and producing complete production lines for machining operations. One of their model systems is the fully automated Aluminum Wheel Production Line, which integrates vertical lathes, horizontal lathes, vertical machining centers, and horizontal drilling centers. This line features an automated delivery system with robot arms for each step of the machining process, including automated flipping, cleaning, and measuring. It is capable of machining aluminum wheels as large as truck wheels in minutes.

Chevalier Quality

Established in 1978, Chevalier Machinery Inc., a subsidiary of Falcon Machine Tools Co., Ltd., is an innovative Taiwan-based CNC machine manufacturer with facilities in the United States (Chevalier Machinery Inc.) and agents in Europe, the Middle East, Mainland China, and South America. The company is publicly traded on the Taiwan Stock Exchange.

Leveraging advanced technologies and engineering expertise, while adhering to stringent quality control measures, ensures that all machines meet or surpass international standards and customer expectations. With their innovative technologies and comprehensive support systems, Chevalier Machinery Inc. continues to empower industries worldwide with efficient and advanced machining solutions.