Founded in 1987, Yung Cheng Shun Industrial Co., Ltd. (YCS) began with a mission to "provide customers with reliable, high-quality precision parts." For over three decades, it has evolved from a small traditional lathe workshop into an internationally renowned CNC precision machining manufacturer, trusted by OEM and ODM clients across various industries.

From a Local Workshop to a Global Precision Manufacturing Partner

Since its inception, YCS has upheld a business philosophy of "high quality, high precision, and high efficiency," continuously specializing in CNC turning-milling compound parts processing. The company, originally named "Cheng Shun Industrial," started production with cam-type automatic lathes as its main equipment.

In 1999, it was renamed "Yung Cheng Shun Industrial Co., Ltd." and introduced Japanese-made CITIZEN CNC automatic lathes, significantly boosting production capacity and establishing a new factory.

Over the years, YCS has continued to innovate and invest in R&D, adopting precision projectors and other advanced inspection equipment. Its business now spans medical devices, automotive and motorcycle parts, bicycles, and optoelectronics.

Committed to its customers, YCS continuously upgrades its internal processes, earning the trust of global OEM/ODM buyers through advanced automated production lines and stringent quality management.

Our core philosophy is simple yet powerful: high quality, high precision, and high efficiency. This is more than just a slogan; it's the driving force behind our continuous investment—from introducing the most advanced Japanese CNC turning-milling machines to establishing a rigorous ISO quality management system. Every step is taken to ensure our clients receive the best products and services.

Comprehensive CNC Machining Capabilities

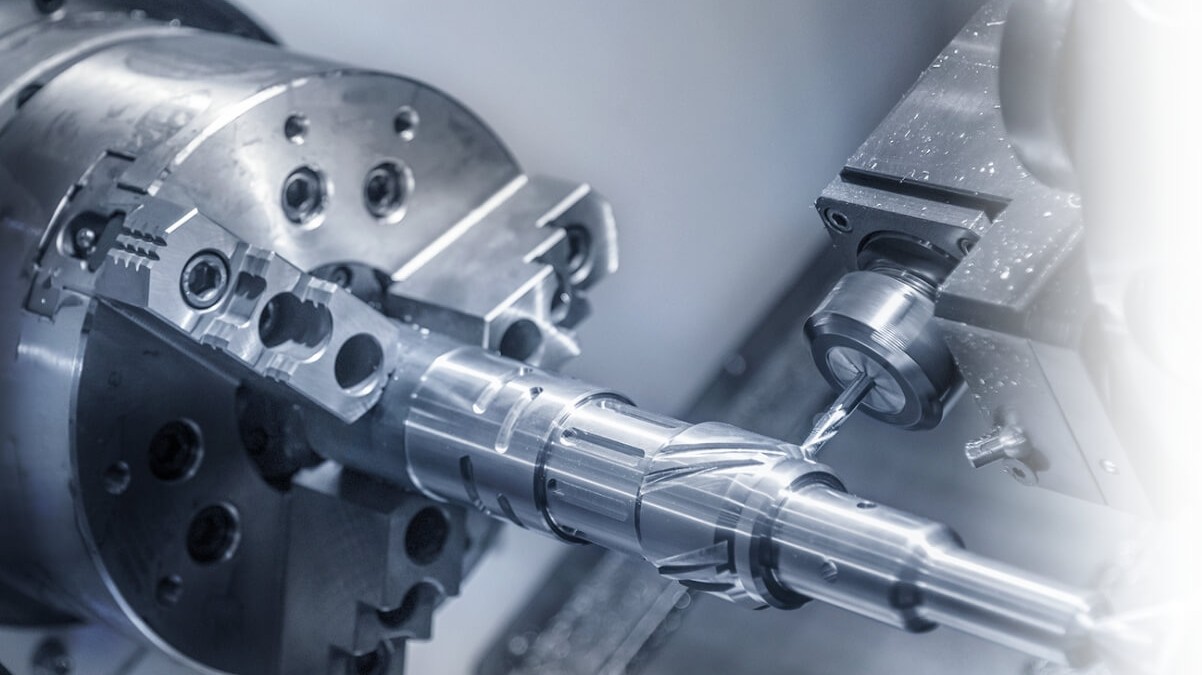

YCS possesses a wide range of high-end CNC turning-milling compound machines imported from Japan, capable of completing various processes such as turning, milling, drilling, and tapping on a single machine. The factory's main equipment comes from renowned brands including CITIZEN, WASINO, MIYANO, MAZAK, and NAKAMURA.

Additionally, the company has introduced multiple sets of automated turning-milling compound machines and 3D imaging measurement instruments to ensure the dimensional consistency of complex parts.

In terms of CAD/CAM software, YCS has implemented advanced process simulation and tool-path generation systems, significantly boosting development and production efficiency, and shortening client validation and mass production cycles.

Through the integration of this equipment and software, YCS can consistently provide high-precision metal and non-metal parts, producing a diverse range of products from electronic components to automotive transmission system parts.

Visible Precision

During the production process, YCS has strict quality control management and multiple inspection procedures. Random or full inspections are conducted at every stage to ensure that part tolerances are in complete alignment with design specifications.

To enhance inspection accuracy, the company has adopted several high-end measuring instruments, including optical projectors and a ZEISS CMM. Before shipping, all parts must pass a strict process inspection and performance test. Only those that meet the highest quality standards are delivered to the client.

YCS operates in accordance with international SOP and ISO standards and has achieved ISO quality management system certification based on principles of sustainable operation, providing clients with reliable and stable product quality assurance.

Serving Diverse Industries, Reaching Global Markets

YCS's machined products are widely used in multiple high-value-added industries. The company provides precision CNC parts machining services for medical devices, aerospace optics, electronic technology, automotive and motorcycle, bicycle, and mechanical hardware sectors. Machining materials include iron, stainless steel, aluminum, copper, titanium alloys, and various polymer plastics.

For instance, YCS has helped manufacture parts for remote-controlled cars and automotive shock absorbers, motorcycle parts, brake and transmission system components, as well as small precision parts for medical equipment and electronic connectors.

To meet the needs of different industries, we also provide professional parts design support and material selection advice, enabling clients to obtain solutions that combine stable quality, cost-effectiveness, and performance in the shortest possible product development time.

Why Leading Companies Choose YCS

The key reason international buyers choose to partner with YCS lies in our comprehensive technical capabilities, stringent quality control, and competitive supply conditions. YCS has advanced Japanese machine tools and a complete inspection center, enabling the rapid and flexible production of OEM/ODM parts that meet high-precision requirements.

At the same time, we maintain reasonable quotations and on-time delivery. Combined with a one-stop design and machining service process, we help clients save on development and logistics costs.

For the long term, YCS actively engages in technical collaboration and quality improvement with clients. We value building long-term, trusting relationships and provide continuous technical support and upgrade recommendations for our projects. Through ongoing R&D investment and process optimization, YCS meets high standards for both stability and innovation, making us a trustworthy partner in precision machining.

Future Outlook – Becoming Your Trusted Strategic Partner

In an era where supply chain stability and precision manufacturing are equally important, YCS is committed to becoming a strategic partner to its clients—not just assisting with design, but also helping to optimize product quality and enhance market competitiveness.

From Taiwan to the world, YCS delivers quantifiable precision and reliable stability.