The manufacturing world is in the midst of a digital revolution. As Industry 4.0 rapidly evolves, factories are transforming from traditional workshops into interconnected, intelligent ecosystems. This shift is not just about adopting new technology; it's about fundamentally changing how we produce goods. Leading the charge are smart machine tools, which are moving beyond simple automation to become autonomous, data-driven assets. This is where companies like CHEVALIER are making their mark, bridging the gap between hardware excellence and digital innovation to redefine the factory of the future.

Machine Tool Trends: Industry 4.0 Drives Smart Manufacturing Innovation

The manufacturing industry is rapidly investing in digitalization and smart technologies, driven by the rise of Industry 4.0. According to a forecast by Grand View Research, the global Industry 4.0 market is projected to grow from approximately $146 billion in 2022 to an estimated $627.5 billion by 2030, representing a compound annual growth rate (CAGR) of 19.9%.

As part of this trend, traditional machine tools are being equipped with sensors and connected to the Industrial Internet of Things (IIoT). This allows companies to monitor the real-time health of their machines using data and implement Predictive Maintenance technologies. The global predictive maintenance market is expected to grow from an estimated $10.9-11 billion in 2024 to $70 billion by 2032.

With the fast-growing demand for small-batch customization, smart machine tools have the potential to shorten processing cycles and boost output through automation and AI-driven analysis. They also offer flexible switching and reprogramming capabilities. Looking ahead, as Digital Twin and AI-adaptive machining technologies mature, machine tool precision and autonomy will continue to improve, promising stronger innovation in smart manufacturing.

Digital Transformation: The CHEVALIER Story

Amid these industrial trends, CHEVALIER stands out with its deep expertise and extensive experience. Since its founding in 1978, the company has focused on the R&D and manufacturing of grinders, lathes, and milling machines, establishing branches and offices in Taiwan, the U.S., and other key locations. It has built a comprehensive design and manufacturing system and operates an advanced, ISO 9001-certified factory to ensure the quality and stability of its equipment. At the same time, CHEVALIER has made long-term investments in R&D and digital transformation, actively establishing a presence in the smart machine tool sector.

CHEVALIER is particularly renowned for the outstanding performance and precision of its core grinding machines, earning the trust of high-precision manufacturers worldwide. The company's machines are distinguished by three key features:

High Precision and Stability : The machines feature a high-rigidity structural design that maintains stable machining accuracy even under heavy cutting loads, making them ideal for precision molds and parts.

Smart Integration : Some high-end models integrate smart control systems that enable automated calibration, remote monitoring, and data analysis, significantly boosting production efficiency and yield.

Diverse Applications : The products can be widely applied across various industries, from traditional automotive parts and mold processing to high-tech sectors like semiconductors and aerospace, offering customized solutions for each.

The Smart System Core: SMART iControl and iMCS

CHEVALIER meets a wide range of processing needs with a comprehensive product line. For instance, its rotary table grinding machine features a high-rigidity ribbed column structure and a fully enclosed hydrostatic work table, which ensures stable operation even under heavy-duty loads.

To empower its machines with intelligence, CHEVALIER developed two smart systems: SMART iControl and the Intelligent Machine Communications System (iMCS). The SMART iControl system boasts powerful computing capabilities and an advanced Human-Machine Interface (HMI), allowing users to execute large-scale machining programs without writing code or entering complex variables. The system also supports network connectivity and data analysis to help managers optimize production processes.

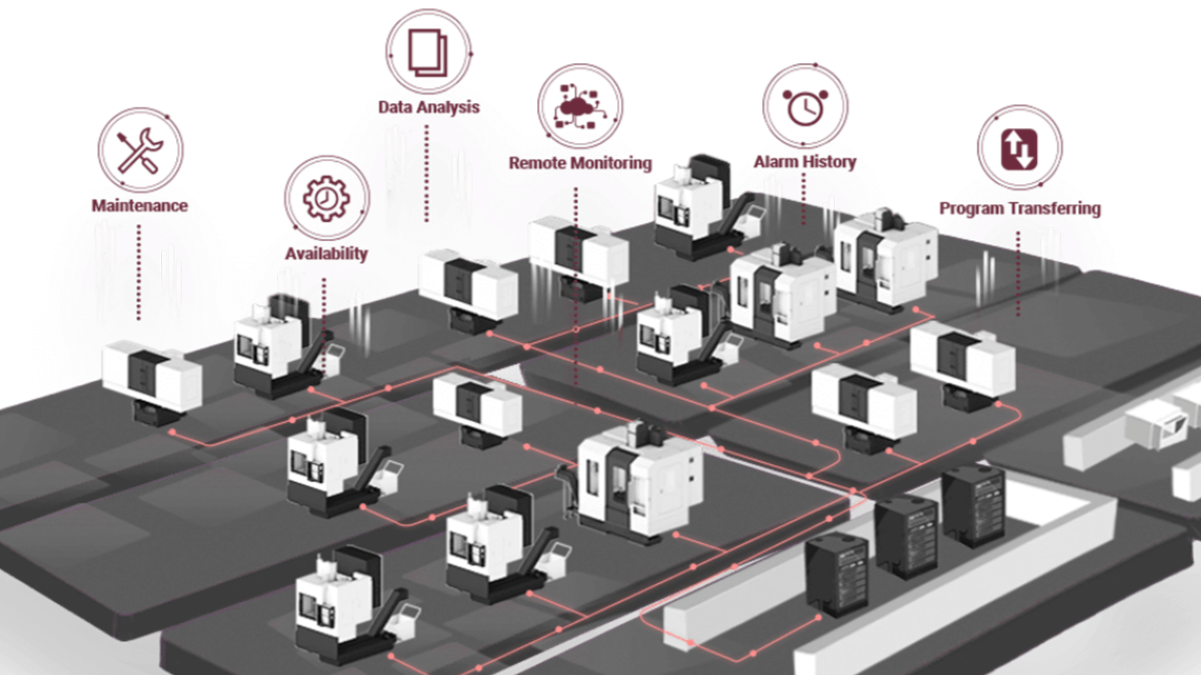

The iMCS system provides comprehensive remote monitoring capabilities. By connecting machines through international standard communication protocols (MTConnect, OPC UA, umati), it enables equipment information transmission, remote monitoring, historical alarm logging, maintenance management, data analysis, and Overall Equipment Effectiveness (OEE) statistics.

Why Choose CHEVALIER?

For companies looking to upgrade their production capabilities, choosing CHEVALIER isn't just an investment in a machine—it's an investment in a complete solution. The reasons are clear:

Deep Technical Expertise : With decades of accumulated knowledge in the grinding machine sector, CHEVALIER provides mature and stable solutions, ensuring reliable product performance.

Global Service Network : CHEVALIER has sales and service locations worldwide, enabling quick responses to customer needs and providing timely technical support and after-sales service.

Flexible Customization : The company excels at customizing solutions based on specific customer needs, offering everything from single-machine design to full-factory automation solutions with high production flexibility.

In the wake of the smart manufacturing wave, CHEVALIER is not only leading the market with its outstanding hardware but is also empowering machines with the ability to "think" and "communicate" through its intelligent systems. This makes CHEVALIER more than just a machine tool manufacturer—it is a critical partner for companies on their journey toward digital transformation, helping to forge a future that is more efficient, precise, and sustainable.