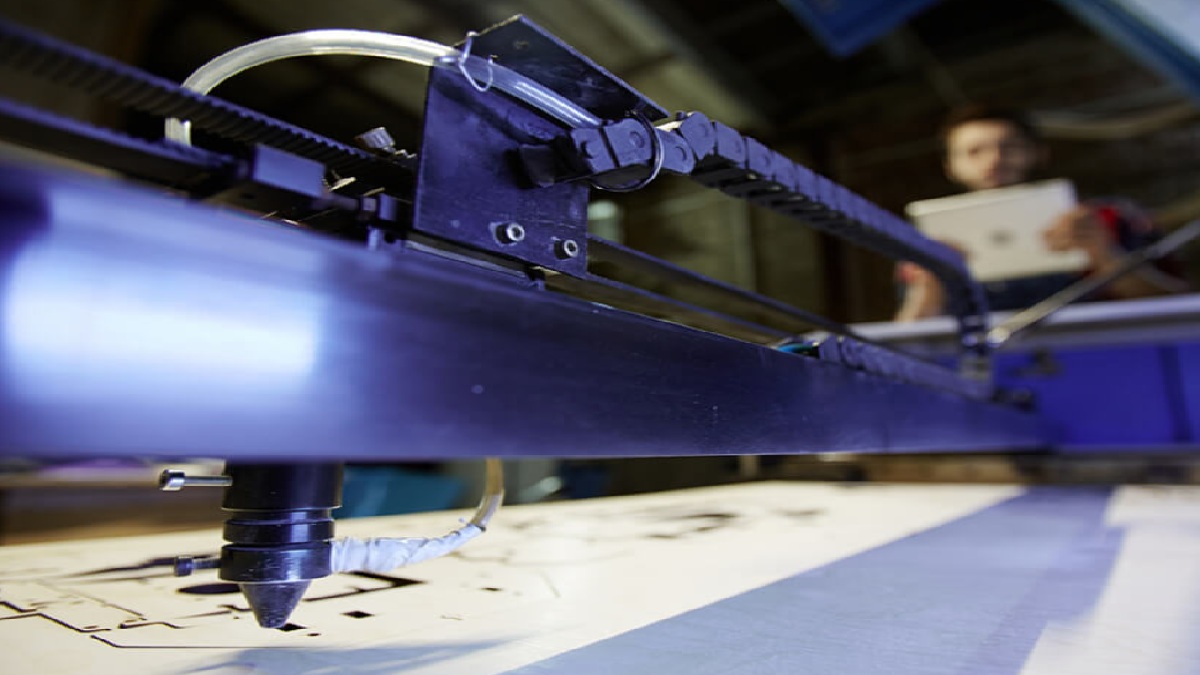

As the global manufacturing and logistics industries rapidly transform toward intelligence and sustainability, intelligent automated warehousing and smart logistics systems have become core technologies enabling enterprises to improve operational efficiency, reduce costs, and enhance market competitiveness. Tailift Co., Ltd., with over 50 years of rich experience, focuses on technological innovation in automated warehousing and logistics systems, continuously providing precise digital transformation solutions to clients across various industries. From high-performance warehouse design to fully automated logistics operations, Tailift is leading technological innovation in the industrial field.

Photo by https://www.tailiftgroup.com/en

Core Technologies and System Highlights of Intelligent Warehousing

Tailift’s intelligent automated warehousing systems include various types of solutions, with each system designed and optimized according to specific industry needs, achieving a balance of flexibility, efficiency, and sustainability:

- Pallet-based System

Suitable for bulk goods and heavy loads, featuring highly modular design supporting flexible warehouse layout and multi-level high-density storage.

- Box-based System

Focused on fast access for small to medium-sized items and fast-moving consumer goods, balancing spatial utilization and operational efficiency.

- Modular Stacking System

Composed of self-developed primary and secondary beam profiles and racks, using a welding-free process with flexible assembly characteristics. It can increase floor space by 200-300%, enabling multi-level high-density storage and vertical handling.

- Storage Rack System

Suitable for small to medium-sized enterprises and factories, also assisting e-commerce sellers in effective categorization and inventory, maximizing warehouse space and improving retrieval efficiency.

- Intelligent Mobile Robots

Equipped with autonomous navigation, environmental perception, and obstacle avoidance features. Designed specifically for warehousing and distribution sites, they efficiently handle pallets and materials, enhancing safety and automation levels.

- IoT Monitoring Platform

Integrates IoT technology to monitor equipment operation in real-time, providing fault warnings, energy consumption monitoring, and maintenance reminders, reducing maintenance costs, and enhancing system stability. The platform supports cloud data integration and analysis, promoting intelligent decision-making and digital management transformation.

Diverse Industry Applications

Tailift’s automated warehousing and smart logistics systems are widely applied across multiple industries, offering customized services based on industry requirements:

- Cold Chain Sector

Tailift develops cost-effective automated freezer and fresh-keeping warehouses for cold chain logistics, supporting ultra-low temperature, high-density storage, and fast access, fully complying with food-grade safety standards to guarantee product quality.

- E-commerce Industry

To address limited warehouse space and frequent logistics demands, Tailift provides stacking platforms and box-type automated warehouse solutions, significantly improving warehouse space utilization and retrieval efficiency.

- New Energy Manufacturing

Independently developed new energy automated production equipment combined with automated warehousing and logistics systems to build unmanned intelligent factories, promoting high-efficiency integration of intelligent manufacturing and logistics.

- Warehousing and Logistics

Tailift self-develops and manufactures various profiles and logistics equipment to meet ultra-high logistics warehouse and automation demands, creating high-density storage full-process intelligent warehousing systems that effectively coordinate storage, sorting, and distribution processes.

- Large-scale Manufacturing

Leveraging over 50 years of manufacturing experience, Tailift assists large manufacturing enterprises in achieving automation of production, transportation, and warehousing, advancing Industry 4.0 transformation and enhancing competitiveness and operational efficiency.

The systems can be flexibly configured according to different needs to accommodate various enterprise sizes and operational complexities, helping users significantly improve operational efficiency and management levels.

Quality Assurance and Structural Safety

Tailift is committed to providing the most reliable automated warehousing systems in the market. All structural profiles of warehousing equipment undergo professional structural calculations and finite element analysis (ANSYS) to ensure stability in seismic resistance and load-bearing capacity. Whether in high-density storage design or large equipment operation, Tailift guarantees product safety and durability. Each system undergoes rigorous quality inspections, including metal material inspection, axial compression testing, and static tests, ensuring long-term stability and high-efficiency operation. Additionally, Tailift offers a five-year warranty service, allowing customers greater peace of mind and ensuring stable, long-term usage under conditions excluding natural disasters or human damage.

Green Energy Saving Promoting Sustainable Future

Upholding the philosophy of green manufacturing and sustainable development, Tailift actively promotes energy saving, emission reduction, and environmental protection goals in the warehousing and logistics fields. To reduce energy consumption and improve operational efficiency, all automated warehousing systems adopt high-efficiency energy-saving motors and advanced intelligent control technologies, effectively lowering energy usage. With the support of the IoT monitoring platform, Tailift collects real-time operational data for energy efficiency analysis and dynamic adjustment, achieving scientific energy management. This not only helps reduce enterprise operating costs but also assists companies in reducing their carbon footprint in line with global environmental trends, thus achieving both economic and environmental benefits.

Innovation-Driven Shaping a New Pattern of Smart Logistics

Tailift actively promotes intelligent warehousing systems toward smart, digital upgrades by integrating artificial intelligence (AI), Internet of Things (IoT), and big data analytics technologies to achieve autonomous operation and precise intelligent decision-making. Tailift’s intelligent mobile robot system can autonomously adjust its route according to operational needs, improving transport efficiency and reducing labor costs. Furthermore, Tailift focuses on deeply integrating smart logistics systems with new energy technologies to build highly efficient, unmanned intelligent factories. These innovative technologies not only enhance system collaboration efficiency but also provide enterprises with more flexible operation models, supporting their progress toward future smart manufacturing and green supply chain goals.