With increasing industrial automation worldwide, CNC rotary tables equipped with 4- and 5-axis capabilities have seen substantial adoption—particularly in applications requiring high precision and heavy load handling. These “smart turntables” enhance tool efficiency, machining accuracy, and production rhythm. According to Verified Market Reports, the global CNC rotary table market was valued at US $1.5 billion in 2024, projected to reach US $2.8 billion by 2033 at a 7.5% CAGR.

Taiwan’s Competitive Strength by the Numbers

Volza’s data highlights that from October 2023 to September 2024, Taiwan exported 221 batches of CNC rotary tables—an impressive 26% year-over-year growth. Taiwan holds approximately 38% of global shipments, second only to Japan, demonstrating strong industrial maturity and engineering capabilities.

AI & IoT Powering the Next Wave

Integration of Industrial IoT (IIoT) and artificial intelligence (AI) enables real-time monitoring of vibration, temperature, and acoustic data to predict maintenance needs. The 5-axis CNC rotary table market reached US $1.2 billion in 2024, with projections estimating US $2.5 billion by 2033—a 9.5% CAGR. These figures underscore the precision-demanding and intelligence-driven direction of the industry.

Transformation Challenges for SMEs

As CNC rotary tables become essential in industrial settings, small and medium-sized enterprises (SMEs) face steep financial hurdles. Beyond the cost of high-precision machinery, ongoing expenses for maintenance, system upgrades, and certifications are substantial. Larger firms, with deeper pockets, are more swiftly transitioning to smarter systems, while many SMEs continue to rely on outsourced solutions or remain on the sidelines.

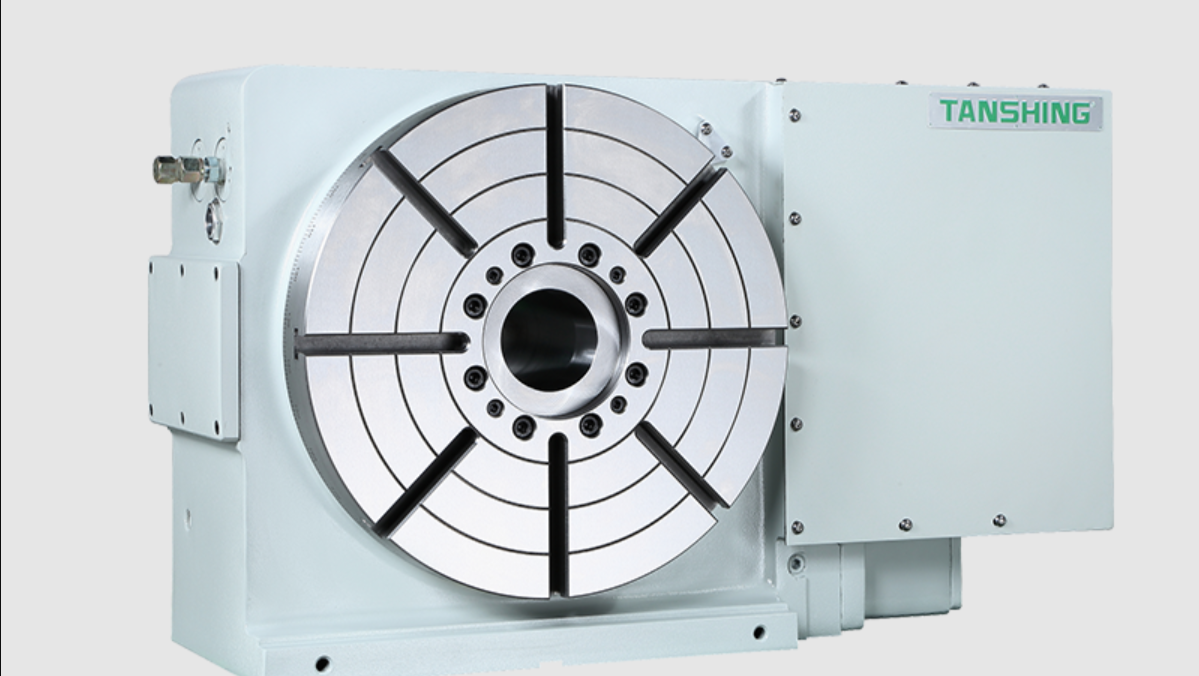

Tanshing’s Winning Strategy: Patents, Quality, and In-House Production

Tanshing Accurate Industrial breaks through this barrier with a clear strategy: in-house R&D and production. With ISO‑9001 certification, the company assures international-standard quality and process control. Their patented dual-lead worm-drive system boosts positioning accuracy, durability, and operational consistency. Their extensive product line addresses needs in aerospace, renewable energy, medical devices, electronics, and electrical industries—reinforcing Tanshing’s capacity to support global projects end-to-end.

Conclusion: Smart + Fast = Real Competitiveness

The global shift toward smart manufacturing offers Taiwan significant advantages in Industry 4.0. However, without patents and robust in-house production, many SMEs risk falling behind. Tanshing, equipped with its proprietary technology, ISO certification, and localized manufacturing, has secured its position in a high-barrier market. By deepening AI/IoT integration and forging strategic partnerships, it’s poised for greater global competitiveness. In the words of the industry: “Only those that turn smartly and swiftly will lead the market.”