- Showing results for

- Metalworking Technology

Metal fabricators aiming to venture into finishing processes should familiarize themselves with two prevalent options—liquid and powder coating—along with the prerequisites necessary for a company seeking to employ either or both.

2023-12-01 14:53:18

Defects are bound to arise during the reprocessing of mechanical equipment or parts related to metal. As a result, the final item's surface treatment process plays a crucial role, serving the dual purpose of enhancing aesthetics and providing protection. This process not only improves the performance of metal parts but also helps prevent rust.

2023-11-24 15:04:29

Defects are bound to occur during the reprocessing of mechanical equipment or metal parts. As a result, the final step of surface treatment holds significant importance. It serves the dual purpose of enhancing the aesthetics and protecting the surface, ultimately improving the performance of metal components and preventing rust.

2023-11-03 14:08:28

Anodization is a surface treatment process, typically performed as the final step in metal manufacturing. It is a dependable and cost-effective method for enhancing wear resistance and adding color to precision machined metal parts, particularly aluminum and other non-ferrous metals.

2023-11-03 13:25:22

Metal stamping refers to the use of the power of punching machinery and the use of molds as metal plate forming tools to produce punching separation or plastic deformation effects to achieve the production technology of parts in terms of size, shape, and performance requirements.

2023-10-12 14:20:48

Welding is a process that uses "heat" and "electricity" to connect two pieces of metal, and the type of welding metal will also affect the welding results and technical requirements; like many professional skills, welding technology also has different levels of difficulty. First understand the most common types of welding introduction, principle teaching, and skill analysis.

2023-10-03 16:38:30

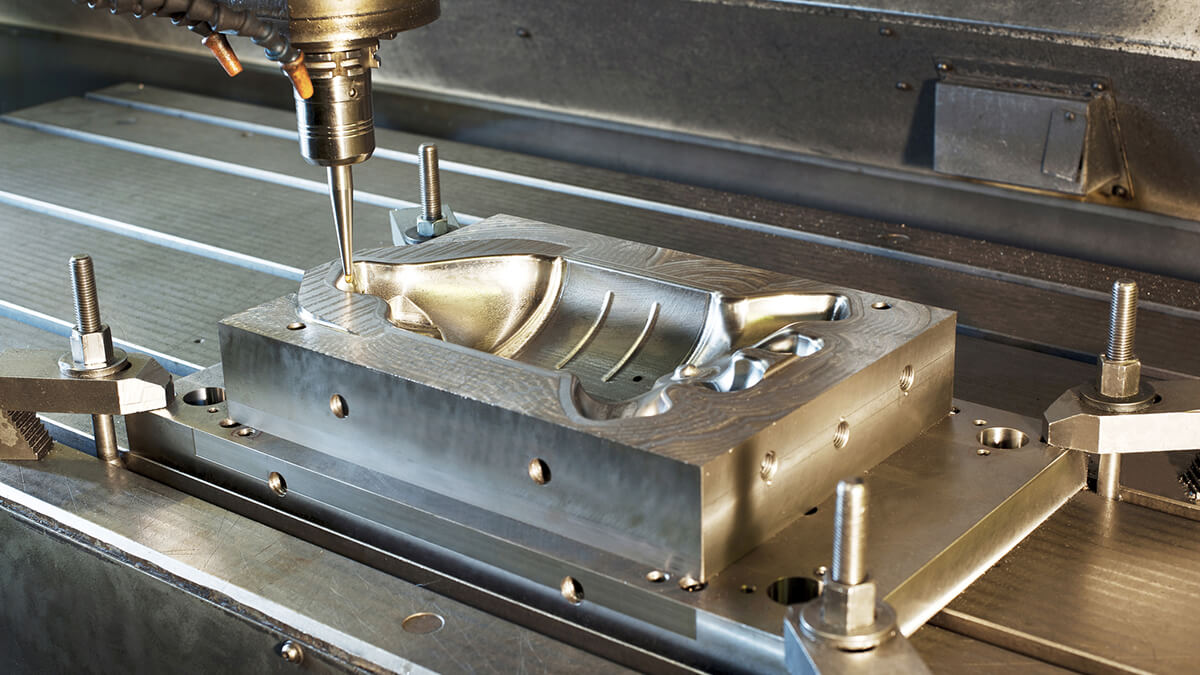

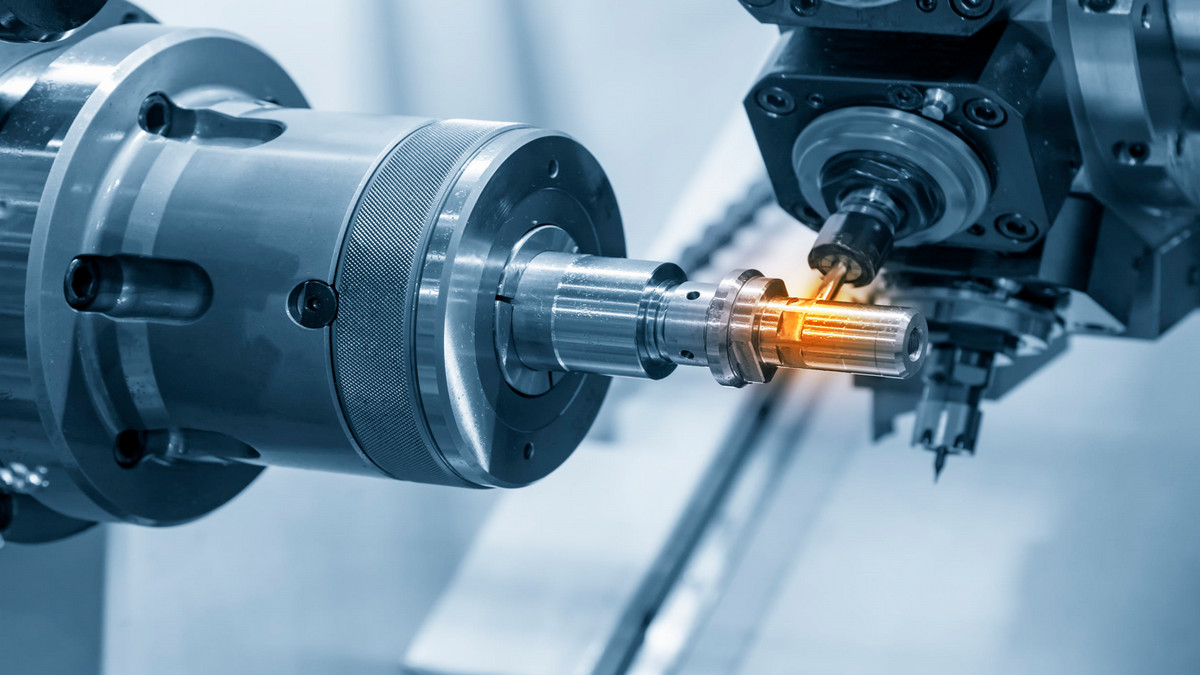

Industrial manufacturing requires machining tolerances. EDM machine can cut metal through electric current.

2023-07-28 11:20:03

Powder injection molding (PIM), including metal injection molding (MIM) and ceramic injection molding (CIM), is a one-shot molding technology that combines high throughput and high precision. This technology has been widely used in many industries to produce various precision parts.

2023-07-14 13:08:55

Metal Injection Molded (MIM) is a high-tech near-net-shape technology that combines traditional powder metallurgy and plastic injection molding processes.

2023-07-14 13:02:38

Stamping is a metal shaping process that involves the use of punches and dies to shape thin-walled metal parts.

2023-06-26 13:48:15

The word comes from the English called plate metal. Generally, some metal sheets are plastically deformed by hand or die-stamping to form the desired shape and size and can be further formed by welding or a small amount of mechanical processing to form more complex parts.

2023-06-16 16:11:25

Welding is a process that uses "heat" and "electricity" to connect two pieces of metal, and the type of welding metal will also affect the welding results and technical requirements; like many professional skills, welding technology also has different levels of difficulty. First understand the most common types of welding introduction, principle teaching, and skill analysis.

2023-05-10 15:12:36

The thread is usually the last feature added to the part. There are other challenges besides the exact parameters required and standard threading issues.

2023-04-25 13:41:33

A grinding machine, or grinder is a widely used abrasive processing process in which a spinning wheel is covered with coarse grains. Cutting pieces of metallic or non-metallic substances from a workpiece to make the surface flat or smooth.

2023-04-12 13:31:11

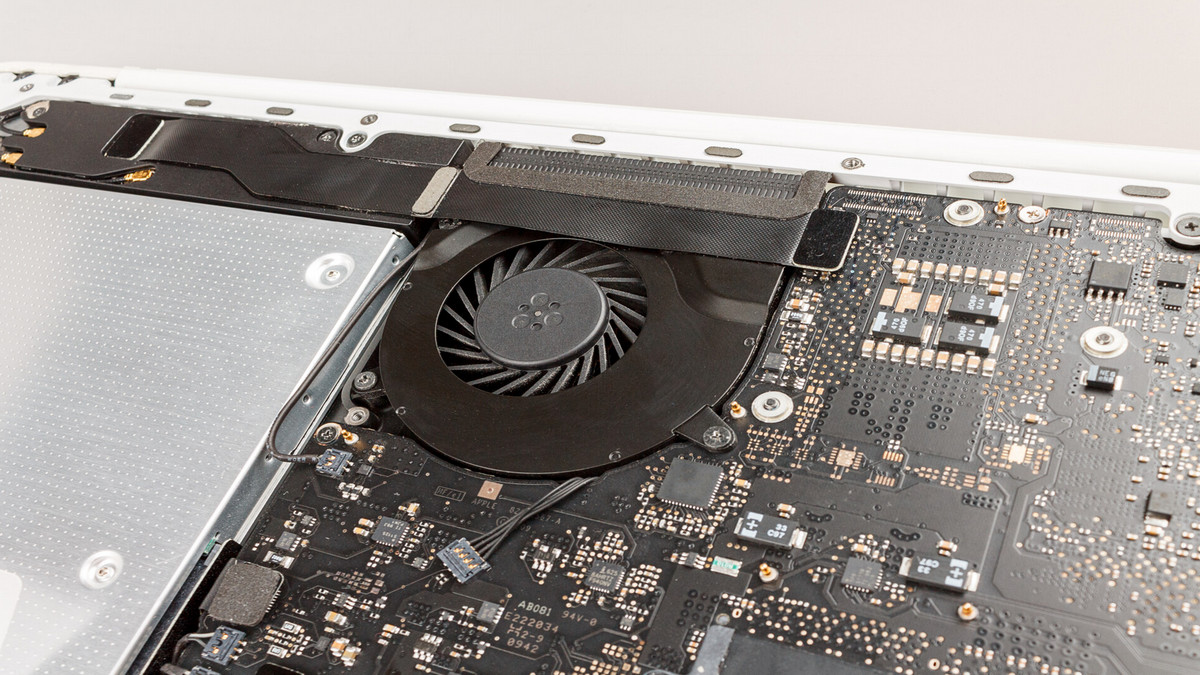

Heat-Assisted Magnetic Recording (HAMR) is a technology that uses laser heat to first heat highly stable media to assist in the magnetic recording of data.

2023-01-16 15:14:42

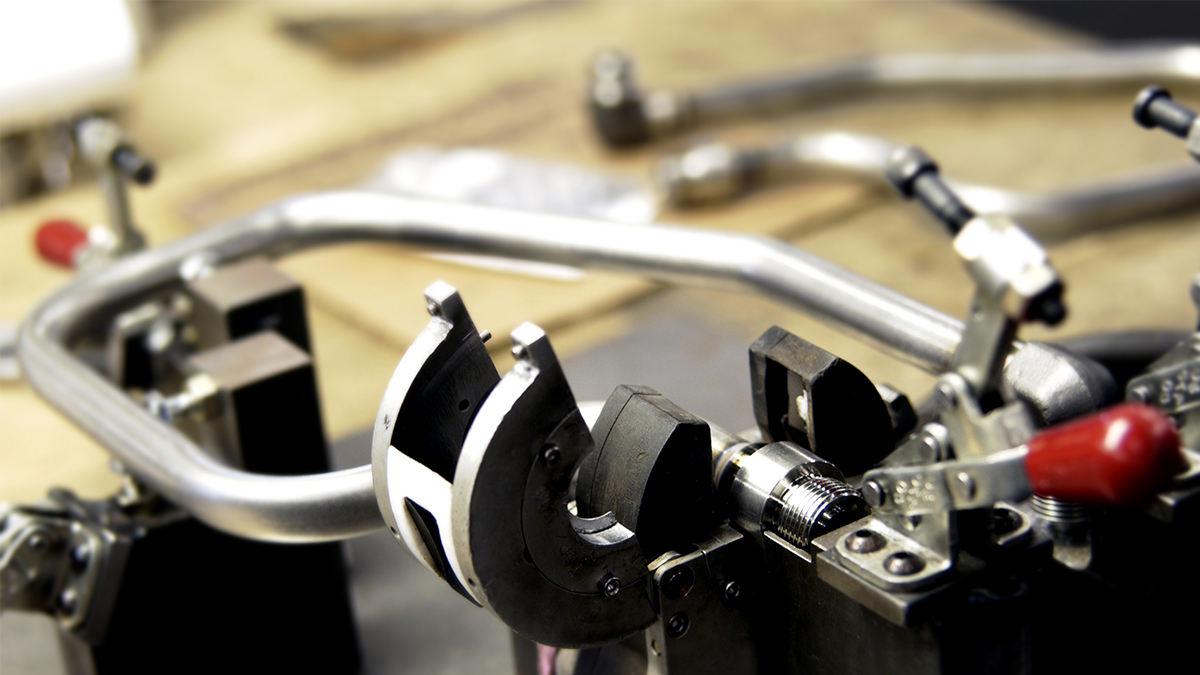

Metalworking is the production activity of applying various processes to metallic materials to manufacture desired parts, assembly line components or overall large structures. Do you know what metal processing is? The process of metal processing is roughly divided into three categories, namely metal forming, metal cutting and metal joining. This article will give a further introduction to metal cutting.

2022-12-12 15:17:20

The aerospace industry has always been a key development industry in all countries in the world. In addition to strict quality system certification and highly complex integration technology, it also has the characteristics of high added value and high industry relevance, which makes all countries take the development of the aerospace industry as a national industry.

2022-11-28 16:34:34

Sintering refers to the transformation of powdery materials into dense bodies, which is a traditional process.

2022-10-25 16:23:50

Powder injection molding (PIM), including metal injection molding (MIM) and ceramic injection molding (CIM), is a one-shot molding technology that combines high throughput and high precision. This technology has been widely used in many industries to produce various precision parts.

2022-10-25 13:16:05

Metal Injection Molded (MIM) is a high-tech near-net-shape technology that combines traditional powder metallurgy and plastic injection molding processes.

2022-10-25 10:20:39

Agree