Heat-Assisted Magnetic Recording (HAMR) is a technology that uses laser heat to first heat highly stable media to assist in the magnetic recording of data.

What is Heat-assisted Magnetic Technology?

Heat-assisted magnetic recording technology is a technology that heats the magnetic storage medium by laser to reduce the coercive force of the medium so that the magnetic head can easily magnetize the storage medium. Due to the superparamagnetic effect, to achieve the goal of ultra-high-density storage, the coercive force of the medium needs to be greatly increased, which significantly increases the difficulty of magnetic head writing. The use of HAMR technology can effectively improve the high-density information writing ability of the magnetic head under the condition of micro-field strength, so it is considered to be one of the next-generation ultra-high-density storage technology approaches that can indirectly deal with the superparamagnetic effect.

Heat-Assisted Magnetic Recording (HAMR) is a technology that uses laser heat to first heat highly stable media to assist in the magnetic recording of data. HAMR technology requires highly stable magnetic composite materials like platinum-iron alloys. These materials can store a single bit in a relatively small area and are no longer limited by superparamagnetic. Many technologies currently used in hard disk storage are still limited by superparamagnetic. The only downside is that they have to be heated to accommodate the changing direction of the magnetic field.

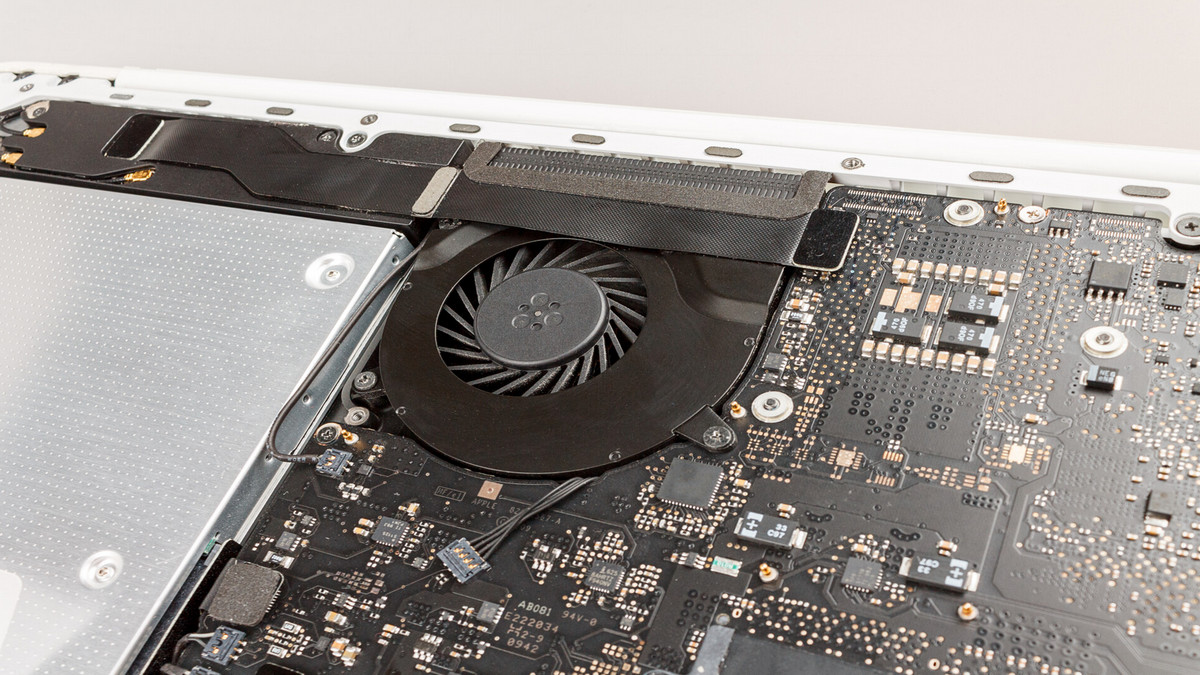

Heat-Assisted Magnetic Recording technology (HAMR) uses micro-laser lamps on the disk head to heat part of the magnetic area before writing. The laser heats the tiny area of the disk in a short time to improve access efficiency.

The second storage technology is to etch tracks or even bit locations on the storage medium and realize precise positioning on the rotating magnetic sheet, without heating to read the data. Regardless of whether it is HAMR or regular media, the ultimate goal is to achieve a capacity density of 1~10TB per square inch of the hard disk at a price close to the current cost. Every major hard disk manufacturer has dabbled in the above two technologies, and these two technologies also have many derivative methods.

A Technological Breakthrough in HAMR Technology

HAMR technology overcomes the current problem that hinders the continuous increase of hard disk storage density. It uses laser beams to precisely focus on the area where data will be written, heats the medium, and avoids the superparamagnetic effect of the magnetic medium. However, after the disk is heated to the curie point by laser, the disk loses its magnetism and superparamagnetic effect. After the data is written, the disk will cool down rapidly to stabilize the written data. Through such precise heating, HAMR can significantly increase the writing density of hard disks. Theoretically, the ultimate storage density that can be achieved with this technology can reach 10TB/square inch.

Although the principle of heat-assisted magnetic recording technology is easy to say, it is not so simple to implement. HAMR requires a new storage medium, a redesigned laser read-write head, a special NFT near-field optical sensor, and many other unused or mass-produced components. So, after talking for so many years, they have not yet fully reached commercialization and achieved mass production and sales.

.jpg)

.png)