Choosing the right CNC machine tool is essential for efficient and precise manufacturing. Instead of focusing on price or brand alone, consider your machining needs, including workpiece size, complexity, material, and automation requirements. This guide helps you select the ideal CNC machine for your production goals.

Workpiece Size and Machining Space

Evaluate your workpiece dimensions and available shop floor space:

- For small precision parts, consider a desktop CNC machine.

- For small to medium-sized components, a Vertical Machining Center (VMC) is suitable.

- For medium to large parts, choose a Horizontal Machining Center (HMC) or a small gantry machine.

- For large molds and plates, a large gantry machining center is recommended.

Selecting the right CNC machine size optimizes workspace utilization and machining efficiency.

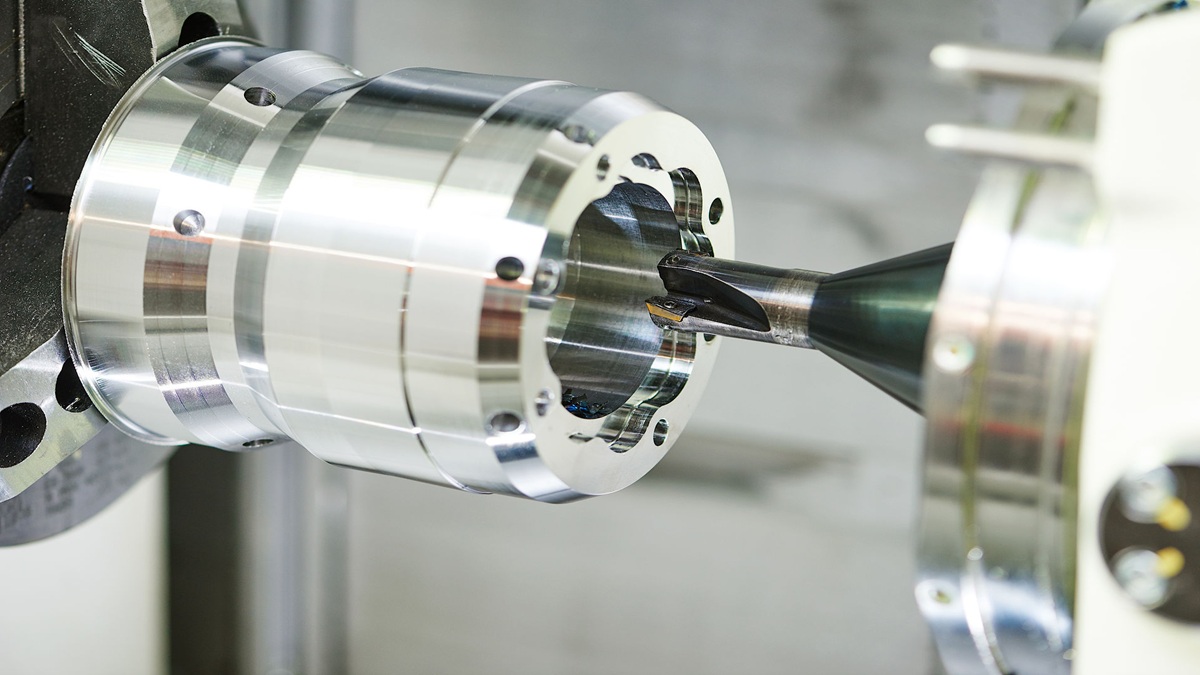

Workpiece Complexity and Axis Configuration

The complexity of your parts determines the required CNC axis configuration:

- Basic 3-axis machines work well for flat surfaces and drilling.

- 4-axis machines add a rotary axis, ideal for multi-face machining and side holes.

- 5-axis CNC machines handle complex contours and inclined surfaces with dynamic tool movement.

- Turn-mill machines combine lathe and milling capabilities, perfect for complex cylindrical parts.

Matching the CNC axis system to part complexity improves precision and reduces production time.

Material and Precision Requirements

Different materials require specific spindle speeds and machine rigidity:

- Use high-speed CNC machining (≥10,000 rpm) for aluminum and plastics.

- Choose machines with high torque and rigid frames for steel and stainless steel.

- For precision molds, select CNC tools with high-precision spindles and low thermal deformation (e.g., BBT-40 tool holders).

Aligning machine specs with materials ensures product quality and longevity.

Automation and Productivity Enhancements

Automation can significantly boost your CNC machining productivity:

- Ideal for mass production or long unattended runs.

- Supports automatic tool changes and reduces downtime.

- Enables integration with robotic arms or rotary tables for complex operations.

Incorporating automation enhances manufacturing efficiency and scalability.

Brand Reputation, Budget, and After-Sales Support

Invest wisely by considering:

- CNC machine brands with strong after-sales service and technical support.

- Machines offering modular design for easy upgrades.

- Compatibility with popular CNC controllers and CAM software for seamless operation.

Reliable support and upgrade paths protect your investment and maximize uptime.

Conclusion: Choose the CNC Machine Tool That Fits Your Specific Needs

There is no one-size-fits-all “best” CNC machine tool. Focus on your workpiece requirements, production volume, and factory conditions to find the most suitable CNC machine that balances precision, efficiency, and cost-effectiveness.

.jpg)

.png)