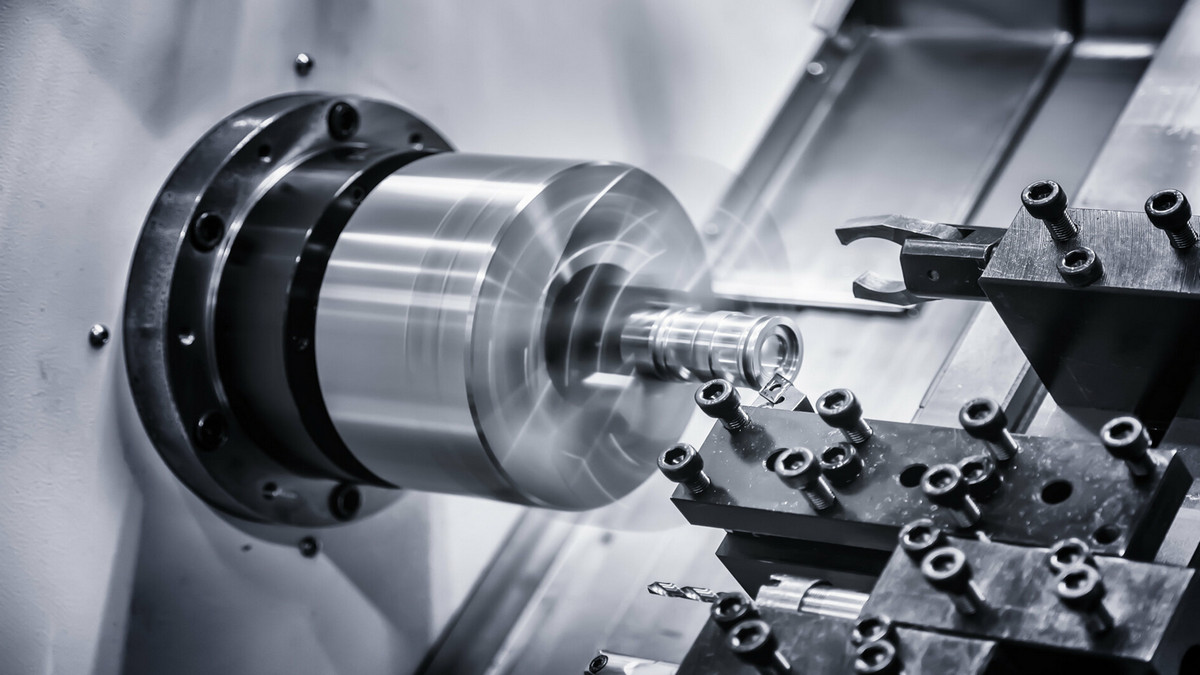

Milling machines are versatile tools that play a pivotal role in shaping and carving materials with precision and accuracy. The milling process involves the removal of material from a workpiece using a rotating cutter. As the cutter moves across the workpiece, it shapes and refines the material, creating intricate designs or precise components. The milling process can mill a workpiece's single face, called face milling, or perform peripheral milling and complex machining operations.

Introduction to Milling Machines: Types and Classifications

Milling machines come in various shapes and sizes, each designed for specific applications. Broadly classified into two main categories — vertical and horizontal milling machines — these tools cater to diverse machining needs.

Vertical Milling Machines

Vertical milling machines, with their spindle axis aligned vertically, are ideal for tasks requiring precision and detail. They find extensive use in industries like aerospace and die/mold machining. Turret mills, bed mills, and knee mills are common subtypes, each serving unique purposes.

Horizontal Milling Machines

Horizontal milling machines feature a horizontally oriented spindle, making them well-suited for heavy-duty tasks. They excel in mass production processes, such as those found in automotive and manufacturing industries. Horizontal mills include plain, universal, and ram types.

Components and Functions of Milling Machines

Understanding the anatomy of milling machines is crucial for efficient operation. Key components and their functions include:

Spindle

The spindle serves as the heart of the milling machine, holding the tool in place and rotating it at varying speeds. The spindle's movement enables cutting, shaping, and finishing processes.

Cutter

The cutter, attached to the spindle, is responsible for removing material from the workpiece. Various types of cutters, such as end mills, face mills, and ball nose cutters, cater to specific machining requirements.

Table

The workpiece is secured on the table, which moves along the X and Y axes. The table's precise movement ensures accurate positioning of the workpiece for cutting operations.

Knee

The knee supports the table and can be adjusted vertically, allowing for changes in the height of the workpiece. This feature enhances the machine's versatility and accommodates different machining needs.

Controls

Modern milling machines boast sophisticated control systems, ranging from manual to computer numerical control (CNC). CNC systems offer automation and precision, making them crucial in contemporary machining processes.

Evolution of Milling Technology

Milling machines can be traced back to the early 19th century when milling processes were primarily manual. The Industrial Revolution marked a significant turning point, introducing mechanization and the development of milling machines.

The Industrial Revolution

During the Industrial Revolution, milling technology advanced rapidly. Milling machines powered by water wheels or steam engines emerged, enhancing efficiency and paving the way for mass production.

Rise of Computer Numerical Control (CNC)

The latter half of the 20th century witnessed the advent of CNC technology. CNC milling machines brought unparalleled precision and automation to the manufacturing process, revolutionizing industries and enabling the production of complex components.

Multi-Axis Milling: Precision in Every Dimension

Traditional milling machines operate along three axes (X, Y, Z). Multi-axis milling extends this capability, allowing simultaneous movement along multiple axes, providing unparalleled precision and versatility. 5-axis milling technology adds rotation around the X and Y axes, enabling complex part manufacturing from virtually any angle.

Advantages of Multi-Axis Milling

Multi-axis milling machines offer the ability to approach a workpiece from various angles, eliminating the need for multiple setups, reducing errors, and enhancing accuracy. The complex geometries and intricate designs in components such as aircraft turbine blades, medical implants, and automotive molds are made possible with the freedom of movement provided by multi-axis machines.

Multi-axis machines can access intricate geometries and angles that would be challenging for traditional 3-axis machines. The ability to approach the workpiece from multiple angles enhances surface finish quality. Simultaneous machining in multiple axes reduces the need for repositioning the workpiece, minimizing setup time and improving overall machining efficiency.

Applications and Innovations in Multi-Axis Milling Machines

Precision is paramount in aerospace manufacturing. 5-axis milling enables the production of complex components such as turbine blades and airfoils with tight tolerances. The medical industry benefits from 5-axis milling in crafting intricate implants and prosthetics, ensuring a perfect fit and optimal functionality. In the automotive sector, 5-axis milling is employed for mold manufacturing, allowing the production of complex shapes for vehicle components.

Optimizing Programming and Toolpath Strategies

For optimization in 5-Axis machining, efficient programming is crucial. CAM software optimizes toolpaths and takes advantage of simultaneous machining capabilities.

Advanced workholding solutions secure the workpiece at various angles to ensure stability during the machining process.

Choosing appropriate cutting tools and considering toolpath optimization minimizes tool changes and reduces cycle times. Continuous toolpaths lead to smoother surface finishes.

Collision detection prevents interference between the tool and the workpiece.

Selecting the optimal number of axes ensures that the machine meets specific production needs and ensures versatility without unnecessary complexity, leading to cost savings.

Navigating the Future of Precision Machining

As we continue to push the boundaries of what is achievable in precision machining, the integration of multi-axis milling and high-speed milling provide unprecedented efficiency and productivity in manufacturing. By understanding the advantages and applications of these technologies, manufacturers unlock new possibilities in every dimension.

.png)