Life is full of inventions that provide convenient services and entertainment: mobile phones, MRTs, notebooks, computers, cars, etc. These exquisite finished products presented to consumers are all processed by a series of complex processes and assembled. Among them, in the industrial process of the product, the machine tool has a very critical position, without it, it is impossible to produce equipment and parts, so it has won the title of "The Mother of Machinery". However, despite its important role, it is little known. Therefore, in this article, we will expose the state of the machine tool industry, understand its contribution to the manufacturing industry, and extend the visible development in the future.

What is A Machine Tool?

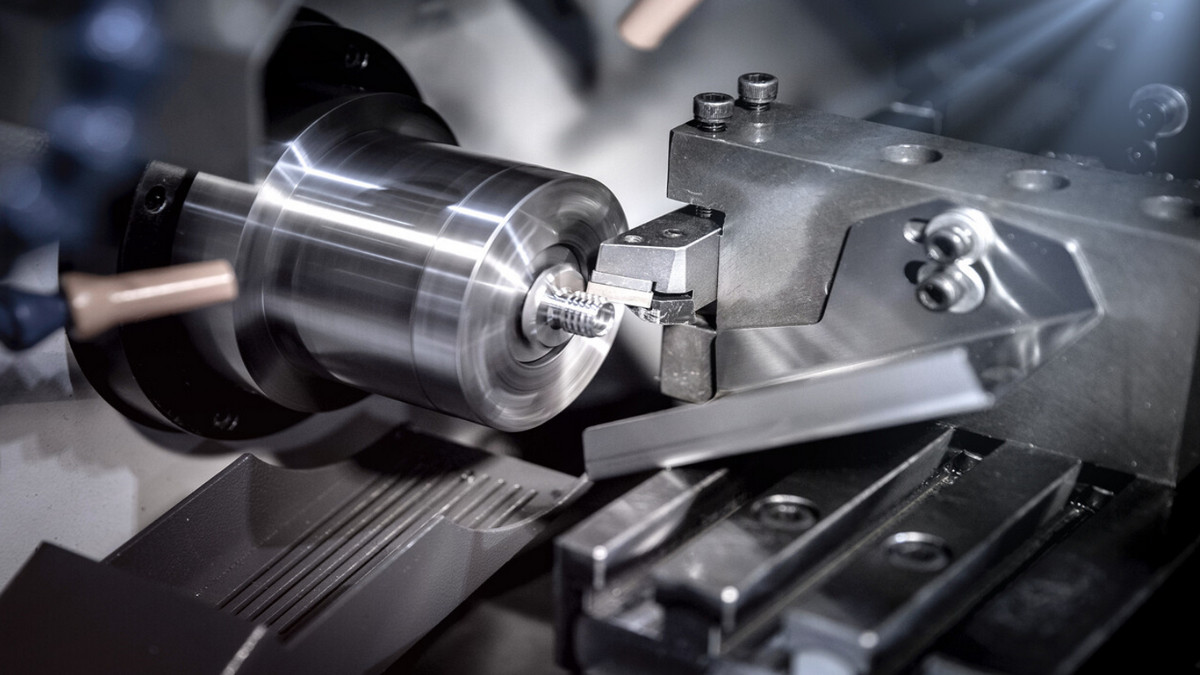

In fact, if we want to trace the development history of machine tools, we may go back thousands of years, because under a broad definition, all tools that are not human-powered and used for processing can be called machine tools. But now the "machine tool" we are introducing refers specifically to a power-driven stationary mechanical device used in manufacturing, which can be used to process metal or other materials into parts. Machine tools in the industrial process mainly include metal cutting and metal forming, and different types of machine tools can complete different instructions according to different tools and movement methods. The function of metal cutting is to remove metal work materials, including lathes, drilling machines, milling machines and non-traditional machining tools. Metal forming is the shaping of metal into a certain shape, such as presses, hydraulic presses, etc.

In addition to the industrial demand brought about by the industrial revolution, the development of machine tools has also set off another wave of climax in the recent wave of information revolution. In fact, the digitalization of machine tools was very early. In the 1950s, when the computer was just born, the first CNC machine tool was born, which can be said to be a very advanced product at that time. The so-called numerical control machine tool (NC Machines Tools) is equipped with a NC numerical control system with a management function on the machine tool table. By inputting the relevant numerical value, after the computer operation, the command is issued to let the machine tool carry out the cutting tool movement, tool change, spindle operation, etc. But unfortunately, after the computer is applied to the machine tool, most of the research and development of the machine tool is directed towards the mechanical device and control performance of the machine tool itself, and the value of the machine tool is rarely upgraded by improving the software technology.

In the 1990s, in order to cope with more and more sophisticated industrial processes, the structure of machine tools became increasingly complex, and five-axis machine tools and composite machine tools appeared one after another. Although a machine tool equipped with multiple functions is very convenient, it is not very friendly to users. Only then did machine tool manufacturers realize the importance of software assistance, so they shifted their focus to how to use software to help users better. Operate and exert the best performance of machine tools. Until now, most machine tools have been equipped with functions such as diagnostic monitoring and safety protection. Now, under the trend of intelligence, they have embarked on another wave of turbulent transformation. It is moving forward in the direction of combining the network and integrating virtual and real.

Machine Tool Industry Chain

The top three major producers of machine tools in the world are mainland China, Japan and Germany. Looking at the global trend, we can find that the production base of machine tools has gradually shifted from Europe to Asia, especially mainland China because of its huge domestic demand market, and has advanced by leaps and bounds in recent years.

The upstream industry of machine tools includes the production of parts such as ball screws and linear slides. Due to the complex process of the machine tool and the large number of parts required, most of them are cast by different parts manufacturers, and the components are then handed over to the processing factory for processing. There are many ways, such as turning, milling, grinding, electrical discharge machining, gear machining and laser machining. The processed components are then handed over to the machine tool manufacturer for design, integration and assembly, as well as quality control testing and sales after completion.

Machine tools can be used in machinery manufacturing in different fields, such as aerospace, national defense, automobiles, biomedicine, electronics and other industries. Next, take the automobile industry as an example to illustrate the contribution of machine tools to the industry.

Machine Tools in The Automotive Industry

60% to 70% of the world's machine tools are used in the automotive industry. Whether it is vehicle assembly or auto parts, advanced machine tools and the production lines they consist of are very much in demand. The purchase of machine tools usually accounts for 2/3 of the total investment in fixed assets, so it directly affects the manufacturing cost of automobiles.

In the assembly process of the car, the steel plate is first pressed into the outer shell of the car by a punching machine, which involves the surface and linear design of the car, as well as the stamping design of the mold, and then goes through the steps of welding, door and car cover installation, etc., and then assemble the engine, transmission and anti-vibration systems, and finally the interior decoration, hydraulic system, fuel system and wheels.

The above-mentioned parts, molds, systems, etc. are all processed by the machine tool in the front section, and the assembly process in the latter section also has the participation of the machine tool, which can be said to be a very important application. In addition, machine tools have also played a role in promoting the production process, such as the "aluminum wheel rim automation system". With an automated production line, the high-efficiency production of inner and outer rims can be completed every four minutes. The iron rims are upgraded to aluminum alloy rims that are commonly used today.

The Future Development of Machine Tools

In order to meet the requirements of the demand industry for better quality processes, the development trend of global machine tool manufacturers mainly has two main axes: one is to provide cost-effective high-quality products, and the other is customized system integration and services.

- Cost-effective comprehensive machine tool

In terms of the hardware upgrade of the machine tool itself, the combination of the robotic arm with the machine tool and the automatic process can greatly reduce the personnel cost and gradually become the main product of various machine tool manufacturers. And one machine tool can perform different kinds of machining operations. This kind of "multi-task type" compound machine tool has gradually become a necessary machine tool to meet the flexible market demand and small and diverse production needs. In addition, there are also some manufacturers towards the development of machine tools for composite materials processing, in order to meet the trend of future material replacement, especially for the lightweight transformation of aircraft in the aerospace field. Under the technological evolution and industrial demands, the machine tool has changed from a single professional function in the past to a more complex multi-tasking integration.

- Customized system integration and service

The development of machine tools has also taken the ride of intelligent manufacturing and intelligent automation, and is moving in the direction of combining software and hardware. Equipped with a controller with high technical value, in addition to increasing the accuracy of processing, collecting data and analyzing product usage, and realizing various auxiliary processing and management functions, it can also perform remote maintenance through network diagnosis. Customize customized system services for customers to help achieve higher production efficiency.

In the future, the machine tool can handle more delicate processing, cope with various flexible and diverse processing methods, and move forward in the direction of intelligence and low consumption, and continue to play a key role in the machinery industry.

.png)