An important issue in the development of smart manufacturing is human-computer collaboration, and true human-computer collaboration does not only mean cooperation and coexistence. As the frequency of man-machine operations working together in the same workspace is getting higher and higher, many sensors are also appearing to assist in monitoring and preventive control.

Human-Machine Collaboration in the Internet Era

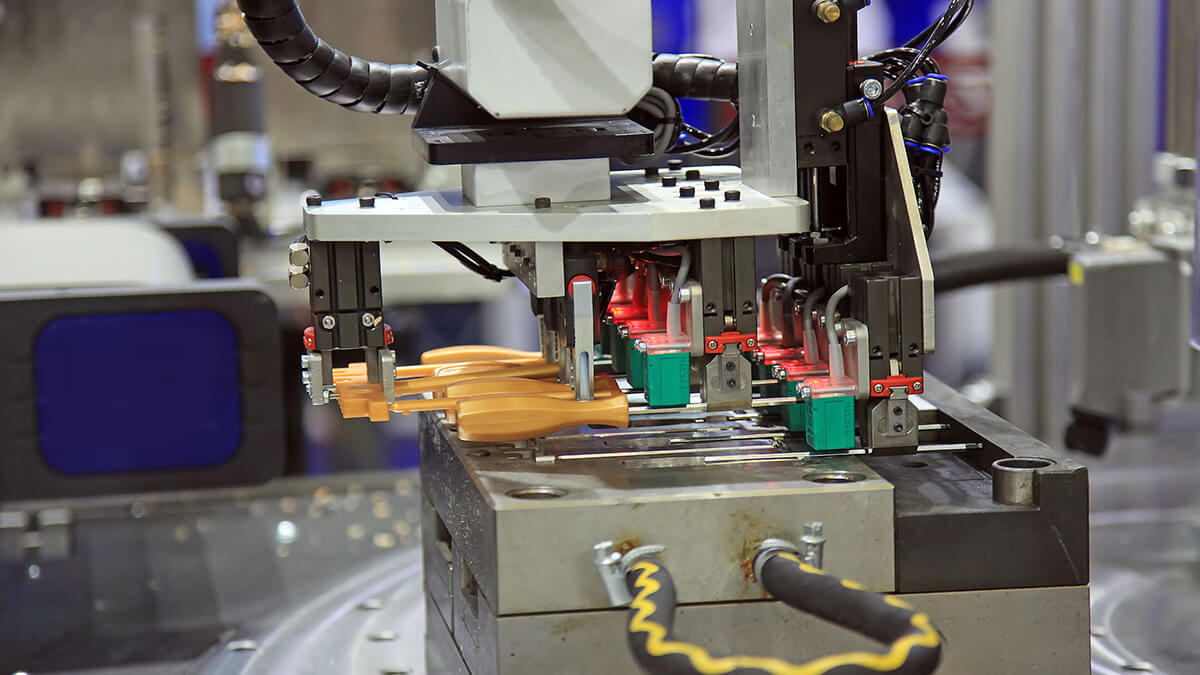

In the smart factory, the relationship between man and machine is closer. From the perspective of the modern division of labor, sensors provide support for the robot's work, giving the robot a vision to respond to tasks in an industrial environment. At the same time, enhanced interaction between humans and machines requires a security solution that can respond with absolute reliability and high flexibility.

Cooperation and coexistence should be turned into real collaboration. Smart factories rely on close interaction between humans and machines. In this so-called collaborative scenario, the strength, speed, and trajectory of the work piece and the robot are all dangerous to the workers. These dangers must be limited by taking your protective measures or taking additional measures.

Flexible security

Today, safety sensors can closely cooperate with the latest machine processes. Intelligent algorithms provide the conditions for, for example, to abandon digital switching safety technology, and make the machine react continuously according to the movement of the person involved. In this way, the machine does not shut down completely every time the worker approaches, but reduces the working speed or adjusts the direction of movement accordingly.

Safety movement in action

"Safe Motion" (Safe Motion) is currently the best available technology. This technology ensures the safety of personnel at all times without interrupting production. The result: significantly reduced downtime and incorrect switching, shorter cycle times, and increased efficiency and availability of machines and equipment.

Functional safety when people collaborate with robots (HRC)

If people and machines collaborate more closely and safely at present, the functional safety of modern production systems becomes an important part of the pursuit of high flexibility. On the way to full collaboration - people and robots share the same workspace and work at the same time - there are also solutions for coexistence or cooperation. SICK has prepared a comprehensive portfolio of safety solutions based on 70 years of experience and knowledge.

Safety expertise in the product portfolio

For example, the programmable safety controller and the accompanying software, together with the safety sensor, can help realize the protection of a large number of dangerous points at the same time. Needless to say, the new generation of safe area laser scanners can extremely reliably protect dangerous areas, passages, and dangerous points. The efficient safety light curtain is suitable for use as a compact alternative in silent mode, without the need for additional sensors, and can also achieve high availability of hazardous point and hazardous area protection. SICK maximizes the availability of protective equipment and uses its products to minimize machine and equipment downtime.

Smart sensors in connected factories

Connected factories are a prerequisite for Industry 4.0. Every sensor, every machine and all related. People can communicate with each other at any time. This exchange of information does not stop at the factory gate.The interaction between the edge and the cloud is also for production and data management from the outside and facing the outside created conditions. The close cooperation between this technology and the personnel also makes the process more transparent Ming, more production efficiency and economy.

-

Transparent production: Keep up with the content, events, location, and process of the incident. Transparency makes people can track the entire production or supply process in real-time from start to finish and apply it take control.

-

Dynamic and flexible production: Continuously developing automation provides flexible production and very small batch production convenient. Customer demand is the first priority, and ultimately the single piece batch is also profitable.

-

Quality assurance automation: The improved computing power also changes the quality assurance and adoption of cameras the visual capabilities of sensor production management solutions.

-

Mobile platform: More and more mobile systems are integrated into the production chain. Unmanned transport of various sizes transport, providing support in almost all industrial fields, ensuring safety and nothing. Therefore, hidden dangers.

-

Human and robot collaboration: True collaboration does not only mean cooperation and coexistence. The same person and machine, the frequency of mutual communication and working together in the work area is increasing.

.jpg)