Generally, the steel blackening (black oxidation) treatment can effectively improve the corrosion resistance, but the protective effect is still quite limited. Oil immersion or subsequent rust prevention treatment is still required to really improve the corrosion resistance and lubricity of the blackened layer.

To improve the anti-rust ability of steel parts, the surface of the steel parts is oxidized into dense and smooth iron oxide with strong oxidants. This thin layer of ferro ferric oxide can effectively protect the inside of the steel from oxidation. The ferro ferric oxide oxidized at high temperature (about 550 ℃) is sky blue, so it is called bluish treatment. The ferric oxide formed at low temperature (about 3 50 ℃) is dark black, so it is called blackening treatment. In weapons manufacturing, the bluish treatment is commonly used; in industrial production, the bluish treatment is commonly used.

Whether it is possible to oxidize the dense and smooth iron trioxide on the surface of steel depends on choosing a strong oxidant. The strong oxidant is composed of sodium hydroxide, sodium nitrite and trisodium phosphate. When they are blue, they use their molten liquid to treat steel parts; when they are black, they use their aqueous solutions to treat steel parts.

Precision-machined parts made of iron-based materials (stainless steel alloys) can specify black oxide as a surface treatment agent, thereby providing extra protection for the parts.

What is black oxide?

Oxide black is a conversion film that is produced by a chemical reaction when the part is immersed in an alkaline salt solution (usually heated). The reaction between the stainless-steel alloy and the solution will produce magnetite on the surface of the part. Magnetite acts as a protective barrier to prevent moisture from corroding the alloy surface. Magnetite is black, so the name is "black oxide".

The solution for this process varies slightly depending on the metal to be applied. It can be applied in cold, room temperature, or hot processing methods, and may require pre-treatment of components according to component requirements.

Another advantage of black oxide is that this process only produces a very thin layer of magnetite, which forms a moisture barrier. Typical thickness is 5-10 millionths of an inch (.000005 inches -.000010 inches). This means that the process will not affect the dimensional stability of the part. Another advantage is that no metal is removed or deposited from the surface of the part during processing. Unlike painted or electroplated surface treatment, black oxide will not chip or flake.

It can also be post-treated (oil, wax or varnish), depending on the application and aesthetic requirements of the final part, changing the surface treatment from satin to gloss. After trimming, it can also provide improved lubrication characteristics, which helps to make parts run more smoothly and easy to connect with the matching parts. The oil also enhances corrosion protection. If black oxide is not specified in any post-treatment, the treatment process is usually completed with oil.

The application of black oxide can be specified

- Components that must meet MIL-DTL-13924D specifications for military applications.

- Surgical instruments in a light-dense environment can reduce eye strain.

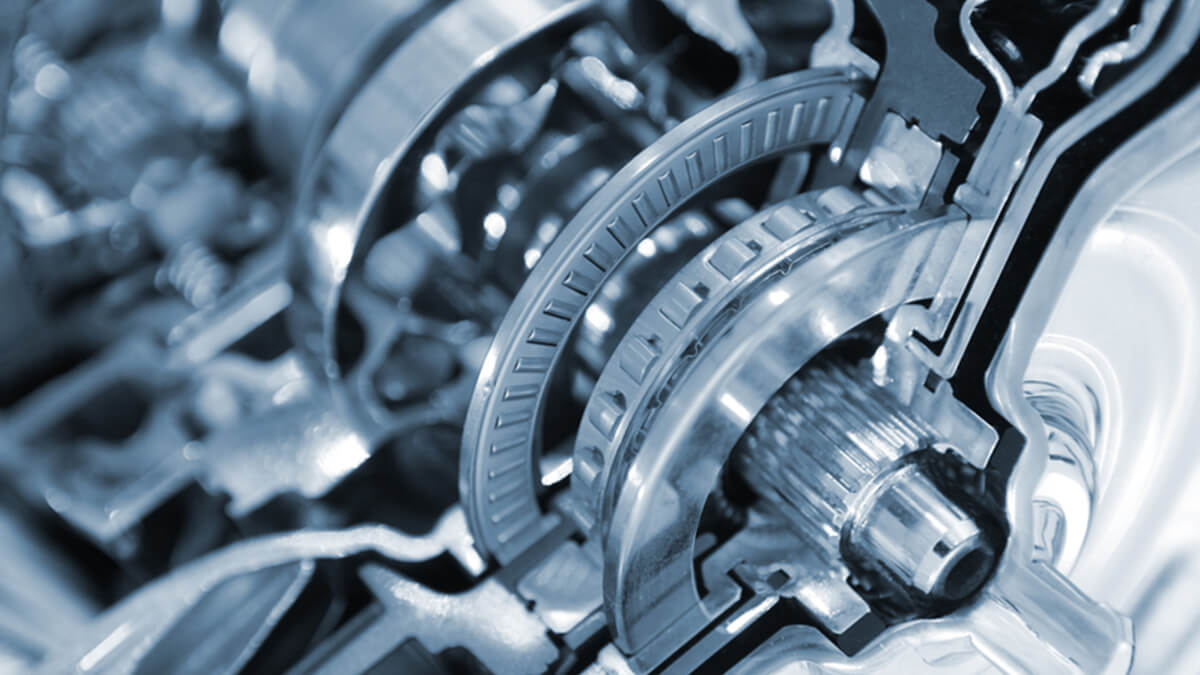

- For gears, fasteners, and hardware used in components requiring corrosion resistance.

- Black hardware used for construction and furniture assembly adds to the aesthetic appeal of the final product.

Important factors to consider when specifying black oxide.

- The period of protection

- Indoor or outdoor applications

- Desired appearance (matte or gloss)

- Environment (humidity, steam, temperature)

- The end use of the product

Test options

There are various test options for black oxide surface treatment. If any of these tools are needed, they will be specified on the part drawing, and this test usually adds time and cost to the test.

Stain Test

This process will determine if there are black powdery residues on the parts when rubbed by hand. The test is carried out after completion.

Relative Humidity - This procedure will use the ASTMD 2247 standard specification (for testing the water-resistance of coatings at 100% relative humidity) to test corrosion resistance.

.png)