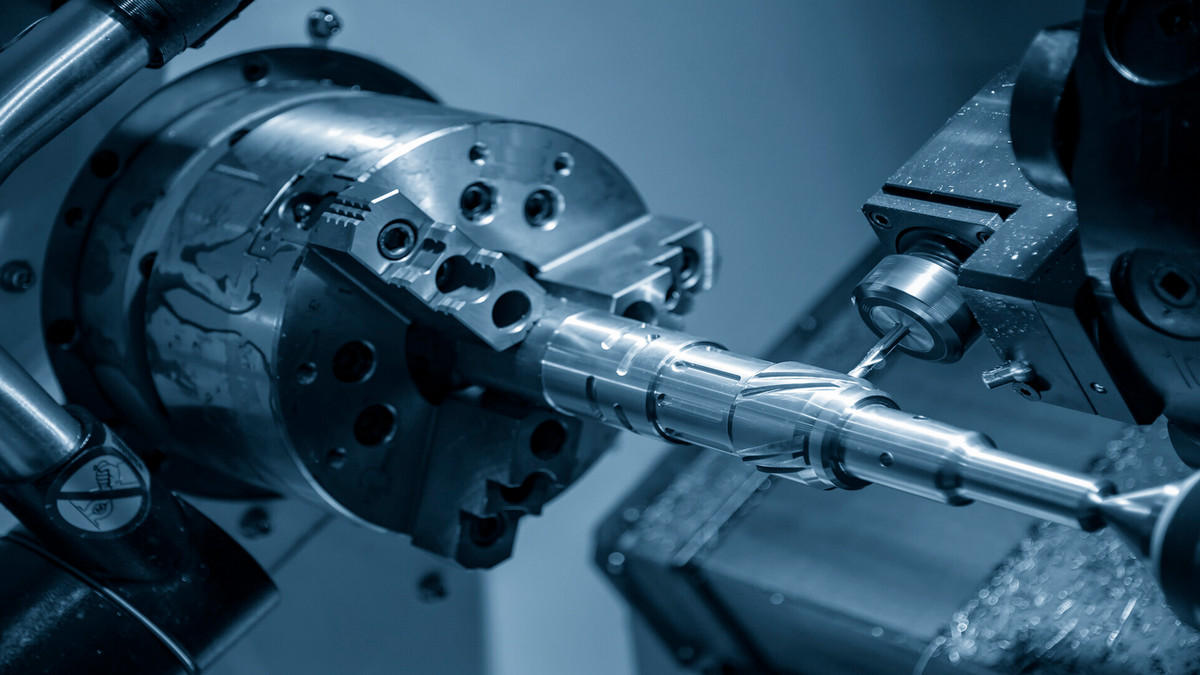

Five-axis CNC machining means that there are at least five coordinate axes (three linear coordinates and two rotary coordinates) on a machine tool, and can be processed simultaneously with coordinated movements under the control of the computer numerical control system. The axis of the CNC machine tool means the motion axis, which is actually a coordinate axis in space, such as the XY axis of the coordinates. There is no motion axis with an independent controller and motor drive system.

According to statistical data, the CNC machining center is one of the most widely used CNC machine tools in the current industrial production industry. With a variety of processing techniques, its development represents the level of a country's manufacturing industry. Its main features are:

Features of Machine Tools

According to statistical data, the CNC machining center is one of the most widely used CNC machine tools in the current industrial production industry. With a variety of processing techniques, its development represents the level of a country's manufacturing industry. Its main features are:

Fully Enclosed Protection

The CNC machining center has a protective door. When processing, closing the protective door can effectively prevent personal injury accidents.

Use of Multiple Tools and the Tool is Automatically Exchanged

The CNC machining center is equipped with a tool magazine and an automatic tool changer. The required tools are loaded into the tool magazine before processing, and the tools can be automatically replaced by program control during processing.

The Process Is Centralized, and the Processing Is Carried Out Continuously

CNC machining centers usually have multiple feed axes (more than three axes), or even multiple spindles, and the number of linkage axes is also large, such as three-axis linkage, five-axis linkage, seven-axis linkage, etc., so it can automatically complete multiple planes and the processing of multiple angular positions to achieve high-precision processing of complex parts. Milling, boring, drilling, expanding, reaming, tapping, etc. can be completed in one clamping on the machining center, and the processes are highly concentrated.

High Automation, High Precision, High Efficiency

High spindle speed, feed speed, and rapid positioning accuracy. Through the reasonable selection of cutting parameters, the cutting performance of the tool can be fully exerted and the cutting time can be reduced. The entire processing process is continuous, various auxiliary actions are fast, and the degree of automation is high. Reduced auxiliary action time and downtime, therefore, the production efficiency of the machining center is high.

Use Multiple Workbenches and Workbenches are Automatically Exchanged

If there is an automatic exchange table on the CNC machining center, one table can be processed while the other table completes the clamping of the workpiece, thereby greatly shortening the auxiliary time and improving the processing efficiency.

Powerful Functions, Tend to Compound Processing

It has complex turning functions, grinding functions, etc. For example, the circular table can drive the workpiece to rotate at high speed, and the tool only performs the main motion without feeding, completing similar turning processing, which enables the machining center to have a wider processing range.

The Best Benefits Can Be Achieved Under Appropriate Conditions

That is to say, in the process of use, the advantages of the machining center must be exerted in order to fully reflect the benefits, which is very important for the rational use of the machining center.

Powerful Function, High Investment

Due to the high degree of intelligence, complex structure and powerful functions of CNC machining centers, the one-time investment and daily maintenance costs of machining centers are much higher than those of ordinary machine tools.

What is A Five-Axis Machine Tool?

In recent years, five-axis CNC machining centers have been more and more widely used in various fields. In practical applications, whenever people encounter the problem of efficient and high-quality machining of special-shaped and complex parts, five-axis linkage technology is undoubtedly an important means to solve such problems. More and more manufacturers tend to look for five-axis equipment to meet high-efficiency, high-quality processing. But do you really know enough about five-axis machining?

The five-axis refers to the XYZ axis, as well as a rotation axis and a swing axis. The rotation axis can be the A axis, the B axis or the C axis. The rotation axis can be rotated 360°. The swing axis is one of the remaining two axes after the rotation axis has been defined. The swing axis can only be used. Swing within a certain angle (such as plus or minus 90°) and cannot rotate 360°.

The commonly used three-axis linkage is the X-axis, the Y-axis and the Z-axis. The four-axis linkage is X-axis, Y-axis, Z-axis and A-axis. Five-axis linkage refers to the five axes of X, Y, Z, B, and C.

A five-axis machine tool refers to a machine tool that contains any five axes of X, Y, Z, A, B, C, etc. in one machine tool at the same time. Linkage refers to the index control of two or more axes of the machine tool. When one axis moves, the other axis moves at a uniform or periodic speed. Five-axis linkage means that all five axes can be linked together.

Five-axis generally are divided into spindle deflection type, commonly known as swing head type and cradle type.

Since the workpiece only moves on the C-axis, and even some of the C-axis are rotated by the spindle box, this form has an irreplaceable effect on the processing of super-large and super-heavy parts, but it must be equipped with a power-off protection function to make the machine tool after encountering a sudden power failure, it can find the original way and return to the original point.

The cradle type is suitable for light parts, and the main shaft only moves as a linear axis, so the structure is simpler and more reliable, and the rigidity and accuracy of the main shaft will be better. Coupled with linear motor and torque motor, it can be used for high-speed machining and milling compound machining, which is of great significance in the small precision mold industry.

In production, the most common is usually three-axis machining equipment, which is characterized by the fact that the direction of the tool axis remains unchanged during the machining process. Motion in the space Cartesian coordinate system. The more high-end five-axis can maintain the best cutting state of the tool, improve cutting conditions, effectively avoid tool interference, reduce the number of clamping, complete five-sided machining in one clamping, and improve processing quality and efficiency.

.png)