Industrial robots use a large number of sensors to achieve good operation and control in industrial automation production processes. For example, collaborative robots integrate torque sensors and cameras to ensure the best perspective and safety. What sensors are integrated with industrial robots?

Under the technological upsurge of Industrial IoT, Augmented Reality (AR), cloud computing, and other technologies, global manufacturing companies have begun to build smart factories to realize automation, information, and intelligent industrial manufacturing. Among them, industrial robots will become an important part of this smart manufacturing transformation.

Sensor technology is one of the core technologies for industrial robots, allowing robots to choose paths, perceive changes in the environment, and make correct judgments in complex situations, just like humans. Especially in the field of industrial automation, robots need sensors to provide the necessary information in order to correctly perform related complex operations.

According to market forecasts, by 2021, the global industrial robot sensor market will grow steadily at a compound annual growth rate (CAGR) of approximately 8%. For robot sensing applications including consumers and automobiles, another report clearly pointed out that by 2027, the vision system will alone achieve a market of US $ 5.7 billion, and the force sensor market will exceed USD $ 6.9 billion.

Industrial robots are beginning to use a large number of sensors to ensure good control and operation in industrial automation processes. For example, collaborative robots integrate torque sensors and cameras. In addition to providing a better perspective, they also ensure the safety of the work area. In addition, what sensors are integrated into industrial robots?

One of the main cores of the smart factory-industrial robots

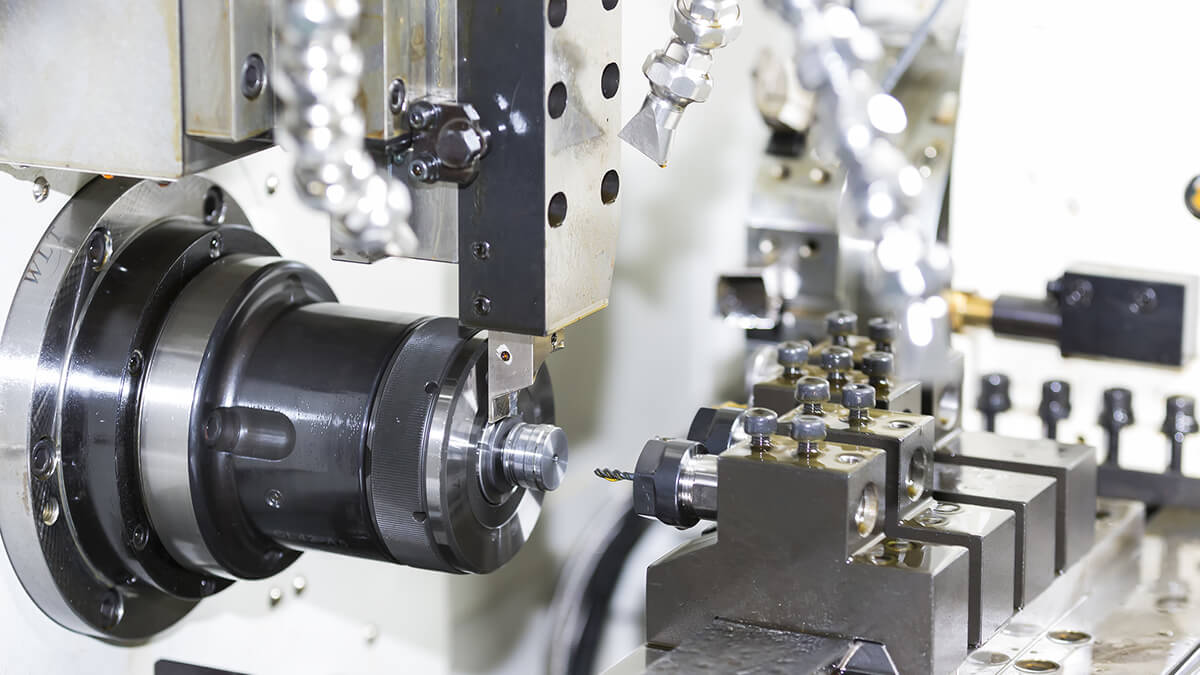

Robot automation is rapidly progressing technology. In just a few decades, industrial robots have become universal devices in factories worldwide.

An industrial robot is a mechanical device that automatically performs work. It can accept human commands, execute pre-arranged programs, or act according to instructions defined by artificial intelligence (AI) technology. In addition, it can overcome the impact of the harsh environment on production, reduce the use of labor, ensure the safety of workers, and at the same time help the factory save production costs and improve production efficiency, thereby ensuring product quality.

Industrial robots are multi-degree-of-freedom machine devices that can automatically perform work and realize various functions according to their own power and control capabilities. They are composed of three major parts: machinery, sensing, and control. These three major parts are divided into six subsystems. They are:

- Drive system: place a transmission device for each joint, that is, each degree of freedom of movement, to make the robot move.

- Mechanical structure system: It consists of three parts: body, arm, and end manipulator. Each large piece has several degrees of freedom, forming a multi-degree-of-freedom mechanical system. The arm is generally composed of an upper arm, a lower arm, and a wrist. The end manipulator is an important part that is directly mounted on the wrist. It can be a two-finger or multi-finger claw, a paint spray gun, a welding gun, etc.

- Sensing system: Obtain meaningful information in the internal and external environmental status, improve the maneuverability, adaptability, and intelligence level of the robot.

- Robot-environment interaction system: A system that enables the robot to interact and coordinate with devices in the external environment.

- Human-machine interaction system: a device for humans to communicate with and participate in robot control.

- Control system: according to the robot's operation instruction program and the signal returned from the sensor, it controls the robot's actuator to complete the prescribed actions and functions.

Sensors commonly used in industrial robots

The most commonly used sensors for industrial robots include two-dimensional visual sensors, three-dimensional visual sensors, force/torque sensors, and collision detection sensors.

Two-dimensional vision sensor: Two-dimensional vision is a camera that can perform a variety of tasks from detecting moving objects to locating parts on the conveyor belt. Many smart cameras can detect parts and assist the robot to determine the position of the part, and the robot can appropriately adjust its motion based on the received information.

3D vision sensor: The 3D vision system must have two cameras or laser scanners at different angles to detect the third dimension of the object. For example, part picking and placing are to use 3D vision technology to detect objects and create 3D images, analyze and select the best picking method.

Force/torque sensor: If the visual sensor gives the robot eyes, then the force/torque sensor gives the robot a sense of touch. The robot uses force/torque sensors to sense the force of the end effector. In most cases, the force/torque sensor is located between the robot and the fixture, so that all forces fed back to the fixture are monitored by the robot. With force/torque sensors, applications such as assembly, manual guidance, teaching, and force limitation can be realized.

Collision detection sensor: This sensor comes in various forms, and its main application is to provide a safe working environment for operators, and collaborative robots need them most.

Some sensors can be some kind of tactile recognition system, which senses pressure through a soft surface and sends signals to the robot to limit or stop the robot's movement. Some sensors are built directly into the robot. Some companies use accelerometer feedback, while others use current feedback. In both cases, when the robot senses abnormal force, it will trigger an emergency stop to ensure safety.

To allow industrial robots to collaborate with people, first find a way to ensure the safety of workers. These sensors come in various forms, from cameras to lasers, etc. The purpose is to tell the surroundings of the robot. Some safety systems can be set so that when someone appears in a specific area/space, the robot will automatically decelerate to run if the person continues to approach, the robot will stop working.

The simplest example is a laser safety sensor on an elevator door. When the laser detects an obstacle, the elevator door will immediately stop and retreat to avoid a collision.

Other sensors suitable for different applications

There are many sensors on the market that are suitable for different applications. For example, seam tracking sensors, and tactile sensors are also becoming more popular. This type of sensor is generally installed on the gripper to detect and feel what is being grasped. The sensor can usually detect the force and obtain the force distribution, so as to know the exact position of the object so that you can control the grab position and the grip force of the end effector. There are also some tactile sensors that can detect changes in heat.

Vision and proximity sensors are similar to those required for autonomous vehicles, including cameras, infrared, sonar, ultrasound, radar, and LiDAR. In some cases, multiple cameras can be used, especially stereo vision. Using these sensors in combination, the robot can determine the size, identify the object, and determine its distance.

Radiofrequency identification (RFID) sensing can provide identification codes and allow authorized robots to obtain other information.

Microphones (acoustic sensors) assist industrial robots to receive voice commands and recognize abnormal sounds in familiar environments. If a piezoelectric sensor is added, it can also identify and eliminate noise caused by vibration, and avoid the robot from misunderstanding voice commands. Advanced algorithms can even let the robot understand the speaker's emotions.

Temperature sensing is part of the robot's self-diagnosis and can be used to determine the surrounding environment to avoid potentially harmful heat sources. In addition, using chemical, optical, and color sensors, the robot can evaluate, adjust, and detect problems in its environment.

For humanoid robots that can walk, run, or even dance, stability is a major issue. They require the same type of sensors as smartphones in order to provide accurate position information of the robot. In these applications, a 9 degree of freedom (9DOF) sensor or inertial measurement unit (IMU) with a 3-axis accelerometer, 3-axis gyroscope, and 3-axis magnetometer is used.

Obstacle avoidance sensor aimed at mobile robot

Mobile robots need to use sensors to capture real-time obstacle information, including size, shape, and position information, to achieve obstacle avoidance. There are many kinds of sensors used for obstacle avoidance. At present, common sensors include visual sensors, laser sensors, infrared sensors, and ultrasonic sensors.

- Ultrasonic sensor: The basic principle of the ultrasonic sensor is to measure the time of flight of the ultrasonic wave and measure the distance through d = vt / 2, where d is the distance, v is the speed of sound, and t is the time of flight.

When the distance of D is close enough, the value of L will become relatively large. If it exceeds the detection range of the CCD, although the object is very close, the sensor may not be seen. When the object distance D is large, the L value will be small, and the measurement accuracy will be deteriorated. Therefore, the measurement distance of common infrared sensors is relatively short, which is smaller than that of ultrasonic waves, and at the same time, the distance measurement also has a minimum distance limit. In addition, for transparent or nearly black-body objects, infrared sensors cannot detect distance. But compared to ultrasound, infrared sensors have higher bandwidth.

- Laser sensor: Common laser radars are based on time-of-flight (ToF). The distance d = ct / 2 is measured by measuring the time-of-flight of the laser, similar to the previously mentioned ultrasonic ranging formula, where d is the distance and c is the speed of light Is the time interval from the transmission to reception.

A simpler solution is to measure the phase shift of the reflected light. The sensor emits modulated light of a certain amplitude at a known frequency and measures the phase shift between the transmitted and reverse signals.

The wavelength of the modulated signal is lamda = c / f, where c is the speed of light, and f is the modulation frequency. After measuring the phase shift difference theta between the emitted and reflected beams, the distance can be calculated by lamda * theta / 4pi, as shown above.

- Visual sensor: There are many common computer vision solutions, such as binocular vision, depth camera based on ToF, depth camera based on structured light, etc.

The light emitted by the depth camera based on structured light will produce a relatively random but fixed spot pattern. The light spot hits the object because the distance from the camera is different and the position captured by the camera is also different. First, calculate the offset between the spot and the calibrated standard pattern at different positions. The distance between the object and the camera can be calculated using parameters such as the camera position and sensor size.

The binocular vision distance measurement is also a triangulation method in nature. Due to the different positions of the two cameras, just like the two eyes of a person, the objects they see are different. The same point P seen by the two cameras will have different pixel positions during imaging. At this time, the distance of this point can be measured by triangulation.

Conclusion:

In the "Industry 4.0" era, the emphasis was placed on the integration of automation and informatization. As an important participant in the automated manufacturing process, industrial robots directly affect the level of industrial manufacturing automation.

As the requirements for the complexity and precision of industrial products continue to increase, the applications and requirements of robots are becoming more and more complex and demanding. The computing platform for robots has expanded from traditional PC platforms and embedded platforms to smartphones and tablets for mobile devices, sensors equipped with robots have developed from simple photoelectric switches and touch switches to high-level sensors such as tactile, acoustic, and visual. The communication method between the robot servo system and the control system has also changed from the original "pulse". "Direction" communication cables have been developed to various on-site busbars with more efficient communication and a larger amount of communication data.

The robot control system is changing towards openness. The development of technologies such as the Industrial Internet of Things, big data analysis, and virtualization has also made robots better integrated into manufacturing applications.

.jpg)