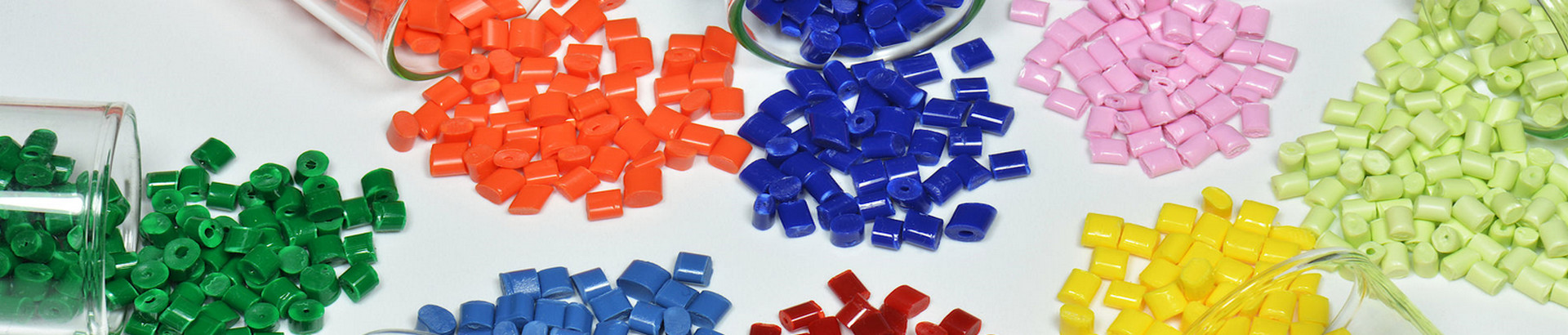

With the wide application of plastic products worldwide, the disposal of waste plastics has become a difficult and urgent problem. One method used to reduce environmental pollution caused by plastics is the granulation of plastics for reuse.

Plastic products play an important role in numerous industrial and agricultural fields. They are lightweight, high strength, corrosion resistance, and easy to process. With the rapid development of the plastic industry, the plastic granulator industry has also developed rapidly. A plastic granulator forms recycled plastic products into plastic granules for reuse. The granulator is not only an indispensable production link for many industrial and agricultural products, but also plays an important role in reducing pollution from plastic, by improving the reuse rate of plastic products.

As the recycled plastics industry grows, granulation is receiving more and more attention worldwide becauses it is a highly sustainable method for recycling plastics.

What is the Granulation Process?

Pelletizing equipment takes recycled plastic material and molds it into pellets. High-temperature melting, plasticizing, and extrusion is used to change the physical properties of the plastic to achieve plasticizing and molding of the plastic. The granulated plastic is them used mainly for making waste plastic films, woven bags, agricultural convenience bags, basins, barrels, beverage bottles, furniture, daily necessities, etc. Granulation is suitable for most common waste plastics and is widely used in the waste plastic recycling industry.

Types of Granulators:

Granulators can be divided into single-screw granulators and twin-screw granulators according to the number of screws. When the single-screw granulator is operating, the plastic is conveyed forward in a spiral shape in the barrel. When the twin-screw granulator is operating, the plastic is transported forward in a straight line in the barrel. When the twin-screw machine is stopped, the material in the machine will be completely emptied, while the single-screw machine will store a small amount of residual material. Most plastic granulation processes can use either single-screw or twin-screw machines.

How Does the Granulation Process Work?

Granulation Process:

Sorting and shedding => Drying => Granulation

Plastics to be recycled are collected are brought to a sorting facility where they are separated into the various types of plastics. They are then washed, shredded, and dried to prepare the material for the granulation process.

Most polymers must be mixed and then pelletized so that they can be used in plastic injection machines to make final products. There are many different pelletizer designs, but the two systems most commonly used are cold pelletizing systems and die-face hot pelletizing systems. The difference between the two is the cooling method used during the pelletizing process.

- Cold pelletizing system: In the cold pelletizing system, a continuous strand of plastic is extruded from a die, and the strand then passes through a cooling zone where it solidifies before it is cut into round or square pellets.

- Hot Pelletizing System: In a die face hot pelletizing system, as the molten plastic emerges from the die it is cut into pellets while still molten, and the pellets are cooled downstream.

The Composition of Plastic Granulator:

The main body of the plastic granulator consists of the extrusion system, a transmission system, and a heating and cooling system.

Extrusion system:

The extrusion system of the plastic granulator includes a screw, a barrel, a hopper, a head, and a mold. The plastic is plasticized into a uniform melt through the extrusion system, and under the pressure established in this process, it is continuously fed by the screw to the extruder head.

- Screw: The screw is an integral component of the plastic granulator. It forces the plastic through the extruder head and its construction determines the application range and production efficiency of the extruder. It is made of high-strength and corrosion-resistant alloy steel.

- Barrel: The barrel encases the screw and adds heat to the plastic to melt it. It is generally made of heat-resistant, high compressive strength, durable, corrosion-resistant alloy steel, or lined with alloy steel.

- Hopper: The hopper controls the feed rate of raw plastic material into the granulator. The bottom of the hopper is equipped with a cut-off device to adjust the material flow. Often the side of the hopper is equipped with a viewing hole and a calibration device.

- Die head: The die head converts the rotating motion of plastic melt into parallel linear motion as it is extruded. It must ensure that the molten plastic is smoothly and evenly extruded from the granulator. It is usually made of carbon steel to withstand the necessary molding pressure.

Transmission system:

The transmission system controls the pressure, speed, and torque required to drive the screw during the extrusion process. It is usually composed of a motor, and reduction gears.

Heating and Cooling Devices:

Maintaining even heating and cooling is important during the plastic extrusion process. The barrel, screw and die head may be heated with electric coils, or with heated oil or steam. As plastic is extruded it can be either be cooled in the air or under water. Under water cooling is a faster process, but requires drying of the pellets after extrusion.

Applicable industries for Granulation:

- Pharmaceutical: Granulation and drying of traditional Chinese medicine, western medicine, and biotechnology products.

- Food: Granulation and drying of granules, fruit juice powder, meat powder, seasonings, lactic acid bacteria, and other products.

- Chemical industry: Drying of synthetic raw materials; granulation and drying of powder.

.png)