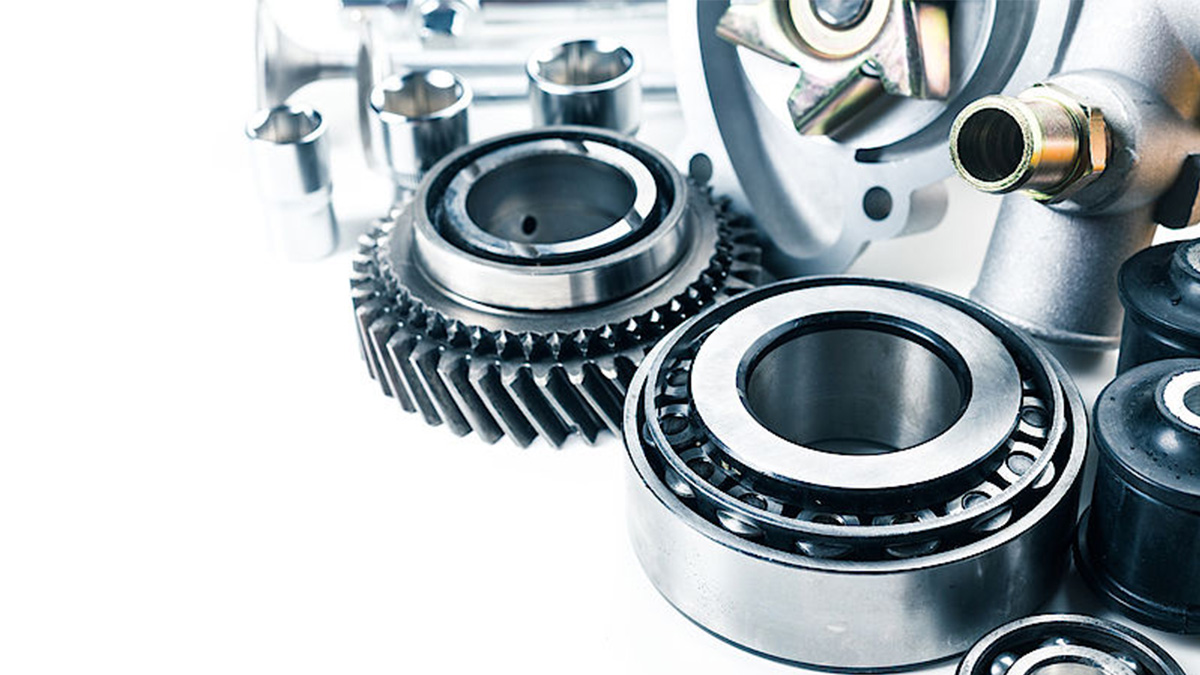

Roller bearings are designed to support the shaft of a rotating body, or the shaft of a linear moving body in a machine.

What is Bearing?

Bearings are devices used to reduce friction and handle stress caused by rotational motion of an object or machine. Bearings are similar to wheels in that they enable the device to roll, thereby reducing friction between the bearing surface and its rolling surface.

The Working Principle of the Bearing:

The bearing uses a relatively simple construction: It contains balls or cylindrical pins inside a casing. Smooth surfaces on the balls, pins, and casings aid in rolling. The casing has an inner ring which fits tightly on the shaft and rotates with the shaft. An outer ring maintains contact with the housing that the shaft rotates in. The housing evenly separates the rolling elements (balls or pins) and guides the rolling elements to move within a guiding track. The rolling elements bear the load as the bearing rotates.

Bearings can be classified according to the direction of the load that the bearing bears:

- Radial load bearings: The weight of the load is placed on the bearing perpendicular to the axis of the rotating shaft.

- Thrust load bearings: Thrust bearings are ball bearings that are used where a force is placed on the bearing parallel to the shaft, such as with helical gear shafts.

Bearings can also be classified according to:

- The size of the bearing

- The shape of the bearing rolling element

- The bearing movement mode

- The number of rows of bearing rolling elements

- Whether the bearing parts can be separated or not

The Function of Roller Bearings:

The main function of a bearing is to support a mechanical rotating body, reduce friction during movement, and ensure rotation accuracy.

Roller bearings use rolling contact between components to replace sliding resistance. This eliminates the static friction encountered when movement is initiated, and reduces power consumption during operation. The bearing fixes the shaft position, controlling its axial and radial movement, ensuring its rotation accuracy.

Other Types of Bearings:

- Roller Bearings vs Sleeve Bearings

A sleeve or plain bearing, is a bearing that has the moving surfaces slide against each other. The surfaces make direct contact to each other, in contrast to rolling bearings where the surfaces are separated by the rolling elements.

- Radial Bearings vs Axial Bearings

Bearings can transmit loads radially (perpendicular to the shaft) or axially (thrust-parallel to the shaft), and in many cases a combination of radial and axial loads may be encountered. The choice of bearing design depends on the relevant application.

Different Types of Bearings

- Sliding bearings:

Any type of bearing that uses sliding friction between moving surfaces, such as sleeve bearings. The sliding surfaces are separated by lubricating oil to reduce friction and surface wear. Sliding bearings work smoothly, reliably, and without noise.

- Deep groove ball bearing:

Deep groove ball bearings are designed to support loads whose line of application is not perpendicular to the bearing axis. They mainly bear the radial load, but can also bear a certain amount of axial load. Deep groove ball bearings are the most common type of bearing produced, with the largest production volume and the widest application range.

- Self-aligning ball bearings:

The self-aligning ball bearing has two rows of ball bearings in the inner ring, and a spherical raceway in the outer ring. The spherical shape of the outer ring raceway allows the shaft to operate at an angle to the bearing direction. Self-aligning ball bearings can compensate for the angular misalignment of the shaft relative to the housing caused by the bending of the shaft or a deformation of the housing.

- Angular contact ball bearing:

The inner and outer ring raceways of angular contact ball bearings are displaced relative to each other to allow the shaft to turn in direction offset from the bearing axis. They can simultaneously accommodate both radial and axial loads. The axial load capacity is determined by the contact angle and increases with the increase of the contact angle.

- Cylindrical roller bearing:

The rollers of cylindrical roller bearings are guided by two ribs in a bearing ring cage. The cylindrical rollers are capable of taking some axial load. These kinds of bearings are easy to install and disassemble.

Uses and Applications of Bearings:

Due to the wide range of applications, the variety and complexity of bearings is extensive. Bearing quality and efficiency varies greatly, with some high-quality bearings designed to meet very strict requirements. Bearing production requires precision manufacturing and accuracy is measured by 0.001mm, compared to ordinary manufacturing tolerances of generally only 0.01mm.

The noise and vibration of a motor depends to a large extent on the bearing quality. During production, close attention is paid to conditions such as the swing difference of tooling, temperature rises of the machine tool etc., to ensure bearing quality. In highly sensitive applications, such as in the rotating device of communication satellites, the bearing performance directly affects the accuracy of communication.

Bearings are used in:

- Automotive: Engines, wheel axels, transmissions, electrical motors, differential gear shafts, steering components etc.

- Electrical: Electric motors, household appliances etc.

- Industrial machinery: Internal combustion engines, construction machinery, railway vehicles, handling machinery, agricultural machinery, high-frequency motors, gas turbines, centrifugal separators, oil pumps, air compressors, fuel injection pumps, printing machinery, motors, generators, reduction gears, etc.

.jpg)

.png)