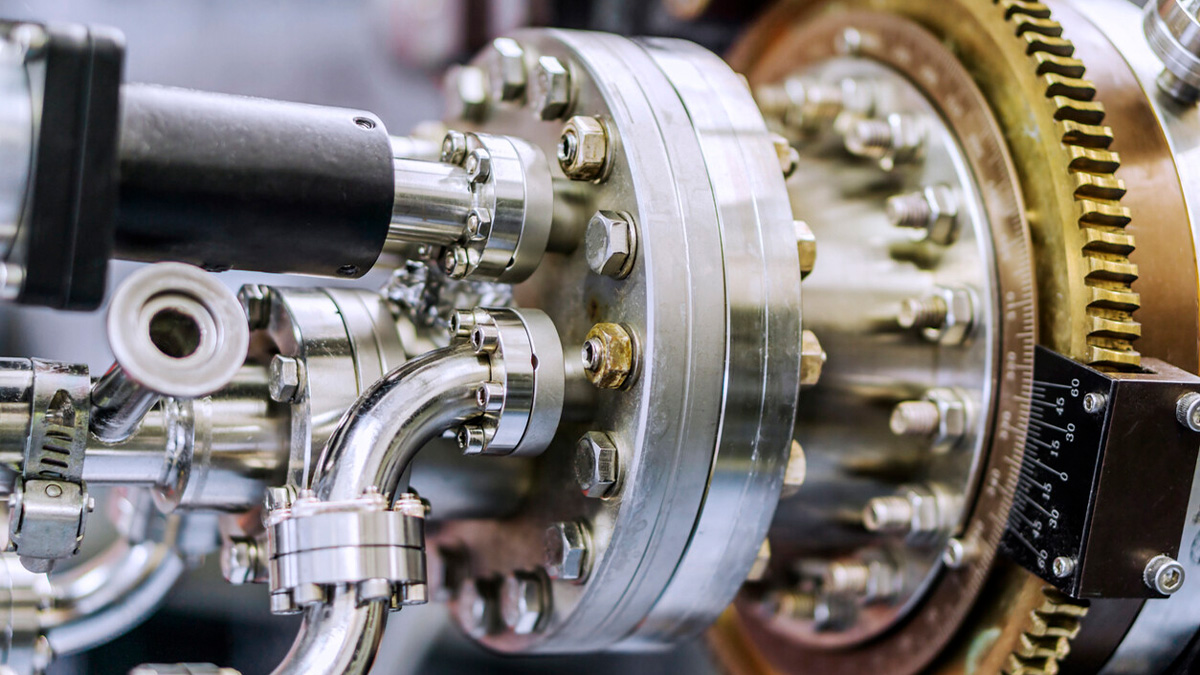

When it comes to fasteners, everyone seems to know a little bit about it. After all, hardware such as screws and nuts are commonplace in life. Fasteners are widely used in many industries and the degree of standardization, serialization and generalization is extremely high.

What Is a Fastener?

“Fastener” is a general term for a type of mechanical part used to fasten two or more parts (or components) into a whole. It is characterized by a wide variety of specifications, different performance uses, and a very high degree of standardization, serialization and generalization. Fasteners are widely used and are in great demand.

Classification of Fasteners

Fasteners can include: Bolts, Studs, Screws, Nuts, Self-Tapping Screws, Wood Screws, Washers, Retaining Rings, Pins, Rivets, Assemblies and Connecting Pair Assemblies, Welding Studs, and Wire Thread Inserts.

- Bolts: A type of fastener consisting of a head and a cylinder shaft with an external thread on the shaft. The bolt is passed through holes in the two parts that are to be fastened and secured with a nut. Bolted connections are used where detachable connections are desired.

- Stud: A type of fastener that is like a bolt, but has no head. Instead, it only has external threads on both ends. When connecting, one end is screwed into a part that has an internal threaded hole, the other end is passed through a “through hole” in the other part being connected. A nut is then fastened to the end of the stud passing through the second part being connected. The stud connection is also a detachable connection.

- Screw: Also a type of fastener consisting of a head and a shaft with threads on the external shaft.

Screws can be divided into three categories according to their purpose: machine screws, set screws and special purpose screws.

1) Machine screws: Mainly used for a fastened connection between a part with a fixed threaded hole and a part with a through hole.

2) Set screws: Mainly used to fix the relative position between two parts.

3) Special purpose screws: An example is a lifting ring screw for lifting parts.

- Nut: Generally, a flat hexagonal or square shaped column with an internal threaded hole. It is usually used with a bolt to connect two parts. Two special kinds of nuts are high-strength self-locking nuts and nylon self-locking nuts.

1) High-strength self-locking nuts are used for road construction machinery, mining machinery, vibration machinery and other heavy equipment.

2) Nylon self-locking nut is a new type of high-vibration resistant and anti-loosening nut which can be used in various mechanical and electrical products within a temperature range of -50-100 ℃. Aerospace, aviation, tanks, mining machinery, automobile transportation machinery, agricultural machinery, textile machinery, electrical products and various types of machinery have seen a sharp increase in the demand for nylon self-locking nuts.

- Self-tapping screw: Similar to a machine screw, but with a special thread for self-tapping. It is used to fasten and connect two thin metal pieces, and is also detachable.

- Wood screw: Also similar to a machine screw, but with a special thread for wood which can be directly screwed into wooden components.

- Washer: A type of fastener ring that is placed between the supporting surface of a bolt, screw or nut and the surface of the connecting parts. It increases the contact surface area of the connected parts, reducing the pressure per unit area and protects the surface of the connected parts from damage.

- Retaining ring: Installed in a groove or hole in the shaft of a machine or equipment to prevent the left and right movement of parts on the shaft.

- Pin: Mainly used for parts positioning, transmitting power. or locking other fasteners.

- Rivet: A type of fastener consisting of a head and a shank. It is used to fasten and connect two parts or components with through holes but is not threaded.

- Assemblies and connecting sub-assemblies: Fasteners supplied in combination, such as certain machine screws or bolts supplied in a combination of special bolts, nuts and washers, such as high-strength hexagon head bolt connection pairs for steel structures.

- Welding studs: A fastener composed of a nail fixed to a part or component by welding so as to be able to connect with other parts.

- Wire Thread Inserts: Sometimes called wire screw sleeves, they have a threaded connection element made of corrosion-resistant wire, shaped like a spring, used to significantly improve the strength and wear resistance of the threaded connection. It is commonly used on low-strength materials such as aluminum, magnesium, cast iron, and plastic.

Processing Technology of Fasteners

With the wide variety of fasteners, their processing techniques are also varied, but commonly used techniques are as follows:

- Wire rolling: A steel billet is heated and rolled to make wire coils for later processing.

- Annealing: A metal heat treatment process in which the metal is slowly heated to a set temperature, maintained for a period of time, and then cooled at a set rate.

- Pickling: A cleaning method using an acid solution to remove oxide scale and rust from metal surfaces.

- Phosphating: An electrochemical process used to form a phosphate layer on the surface of a metal to provide protection against corrosion. It also aids in lubrication by reducing friction.

- Saponification: An oil hydrolysis reaction performed with an alkali catalysis to increase the lubricating properties of a metal surface

- Drawing: Pre-treated wire is extruded to the desired shape and material diameter using a disc die.

- Cold heading: A forging method that uses a die to extrude a metal bar at room temperature. It is used for making screws, bolts, rivets and nuts, etc., and can reduce or replace cutting.

- Turning: A machining process which removes material from a workpiece as it rotates on the machining equipment.

- Threading and tapping: Threads are obtained by extruding or cutting material from the exterior of a shaft, or the interion of a hole in a workpiece.

- Heat treatment: A process where material is heated, kept warm and cooled in a certain controlled environment to change the surface or internal structure of the material.

- Surface treatment: A process that changes the mechanical, physical and chemical properties of the surface layer of a materiel making it different from the substrate material. It is used to increase corrosion resistance, abrasion resistance, appearance, or to obtain other special functional requirements of the product.

.jpg)

.png)