Surface treatment is a process for artificially forming a surface layer with different mechanical, physical and chemical properties on the surface of the substrate. The purpose of surface treatment is to have the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For metal castings, the more commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, and spraying the surface. The following will talk about details among all these different methods.

Generally speaking, there are two explanations for surface treatment. One is surface treatment in a broad sense, that is, the process methods including pretreatment, electroplating, painting, chemical oxidation, thermal spraying and many other physical and chemical methods; the other is surface treatment in a narrow sense. Treatment, that is, only including sandblasting, shot blasting, etc. What we are talking about below mainly focuses on surface treatment in a narrow sense.

In the process of processing, transportation, storage, etc., the surface of the workpiece often has oxide scale, rust molding sand, welding slag, dust, oil and other dirt. If the coating can be firmly attached to the surface of the workpiece, the surface of the workpiece must be cleaned before painting. Otherwise, it will not only affect the bonding force and corrosion resistance between the coating and the metal, but also make the base metal even if there is a coating. It can also continue to corrode under the protection of the layer, causing the coating to peel off and affecting the mechanical properties and service life of the workpiece. Therefore, the surface treatment of the workpiece before painting is an important guarantee and measure to obtain a high-quality protective layer and prolong the service life of the product.

Since there are human beings on the earth, surface treatment is one of the earliest technologies that human beings have mastered. Primitive humans lived an extremely hard life and lived in groups. In order to survive, they made stone tools and applied grinding technology to make the stone tools have sharp edges and produce a "sharp" effect. In the Neolithic Age, the whole body of the stone tools used by primitive people has been ground, the surface is delicate and smooth, and the decorative effect has become the mainstream of the times.

In primitive society, as important as grinding stone tools is primitive painting technology. Primitive humans already have a sense of beauty, and in the late Paleolithic period, they used mineral dyes to paint and paint small personal entertainment items. In the new period, the invention of pottery brought the original color coating technology to its peak, forming the famous color pottery art in history, and opening the prelude to the surface treatment coating technology.

Manual Processing

Such as scrapers, wire brushes or grinding wheels. The rust and oxide scale on the surface of the workpiece can be removed by hand, but manual processing is labor-intensive, low in production efficiency, poor in quality, and incompletely cleaned.

Chemical Treatment

It is mainly to use acid-base or alkaline solution to chemically react with oxides and oil stains on the surface of the workpiece, so as to dissolve it in an acid or alkaline solution to remove rust, oxide scale and oil stains on the surface of the workpiece. Chemical treatment is suitable for cleaning thin plate parts, but the disadvantage is: if the time is not properly controlled, even if the corrosion inhibitor is added It can also cause over-corrosion of steel. For more complex structural parts and parts with holes, after acid pickling, the residual acid immersed in the gaps or holes is difficult to completely remove. If it is not handled properly, it will become the hidden danger of corrosion, and the volatile chemicals, high cost, and difficult chemical discharge after treatment, if not handled properly, it will cause serious pollution to the environment. With the improvement of people's awareness of environmental protection, this treatment method is being replaced mechanically.

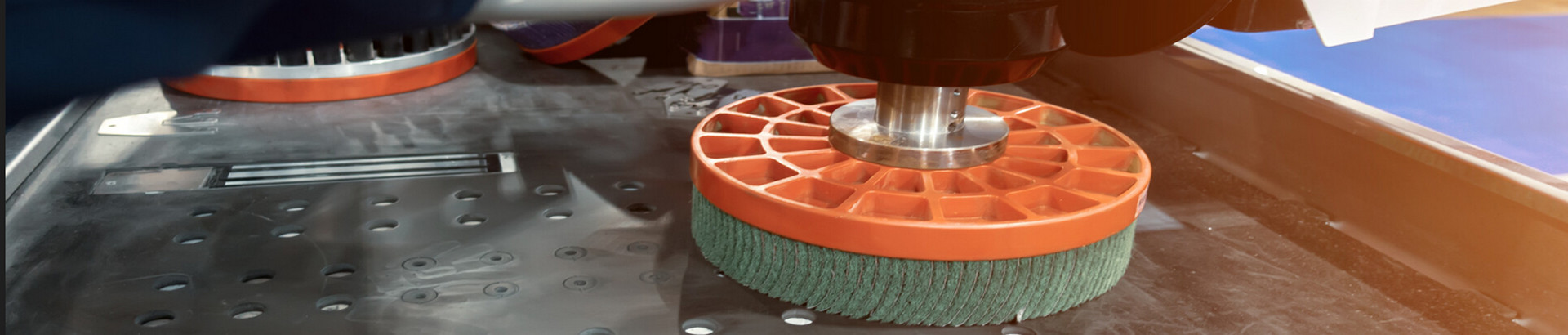

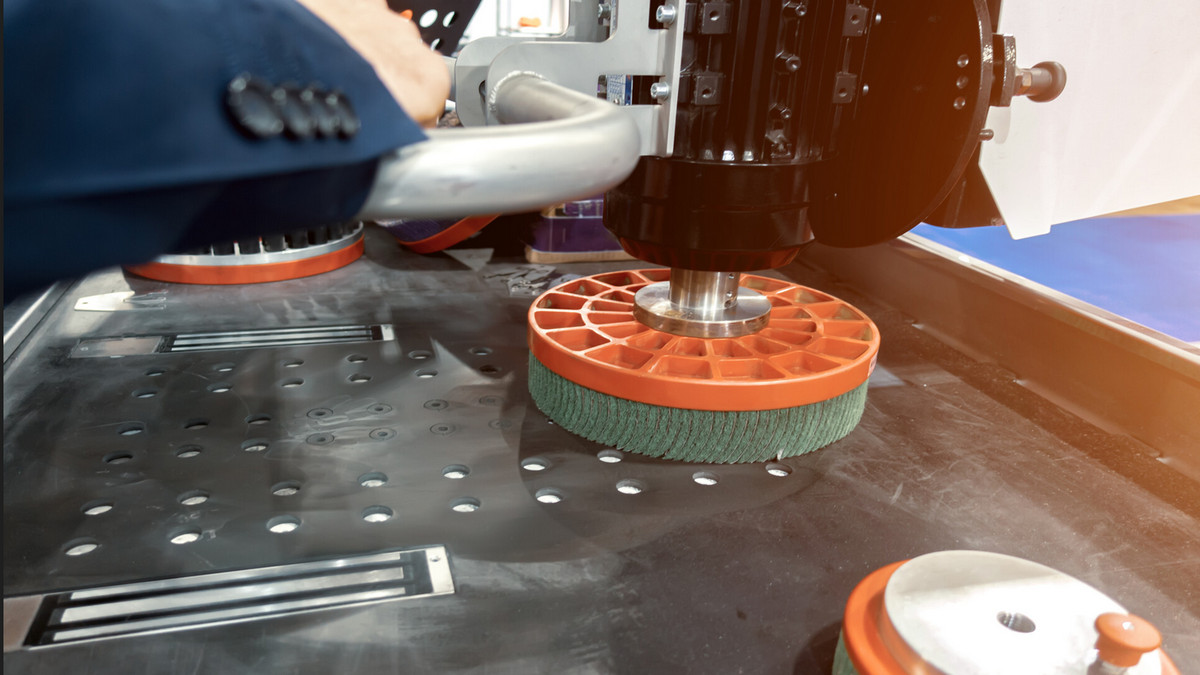

Mechanical Processing

It mainly includes wire brush roller polishing method, shot blasting method and shot peening method. The polishing method is that the brush roller is driven by the motor, and the brush roller rotates at a high speed on the upper and lower surfaces of the strip in the opposite direction to the movement of the rolling piece to remove the oxide scale. The brushed iron oxide scale is washed away by a closed circulating cooling water flushing system. Shot blasting is a method of using centrifugal force to accelerate projectiles and project them to the workpiece for rust removal and cleaning. However, the flexibility of shot blasting is poor, limited by the site, and it is somewhat blind when cleaning the workpiece, and it is easy to produce dead corners that cannot be cleaned on the inner surface of the workpiece. The structure of the equipment is complex, there are many wearing parts, especially the blades and other parts wear quickly, the maintenance man-hours are long, the cost is high, and the one-time investment is large.

Surface treatment with shot peening has a strong impact and obvious cleaning effect. However, the treatment of thin-plate workpieces by shot peening is easy to deform the workpiece, and the steel shot hits the surface of the workpiece (whether shot blasting or shot peening) to deform the metal substrate. After peeling off, the oil film is deformed together with the material, so for the workpiece with oil pollution, shot blasting and shot peening cannot completely remove the oil pollution. Among the existing workpiece surface treatment methods, the best cleaning effect is sandblasting. Sandblasting is suitable for cleaning the workpiece surface with high requirements. However, most of the general sandblasting equipment is composed of primitive and bulky sand conveying machinery such as auger, scraper, and top hoist. The user needs to build a deep pit and make a waterproof layer to install the machinery. The construction cost is high, the maintenance workload and maintenance cost are huge, and a large amount of silica dust generated during the sandblasting process cannot be removed, which seriously affects the health of the operators and pollutes the environment.

Factories that need to do blasting process must fully consider the actual production situation when selecting sand conveying equipment and dust removal equipment, and try to choose equipment with greater power than production needs, because shot blasting equipment generally wears out faster, after long-term use, this or that problem will affect production a lot, and the selection of equipment with higher power will greatly reduce the wasted time and cost of future maintenance.

Insufficient dust removal equipment power not only damages the health of workers, but also seriously affects the visibility of the sandblasting room. The inability of dust to be discharged will also affect the quality of the sand itself and affect the surface roughness of the workpiece.

The manual sandblasting room should be designed according to the actual situation to be more spacious than the workpiece. It should not be too restrained or it will affect the manual work of the workers. At the same time, the lighting conditions must be good. For dry working areas, sandblasting can be carried out outdoors.

Plasma Surface Treatment

Plasma is a collection of positively charged positive particles and negative particles (including positive ions, negative ions, electrons, free radicals and various active groups, etc.), in which the positive and negative charges are equal. Therefore, it is called plasma, which is the fourth state of matter in addition to solid, liquid and gaseous states - plasma state.

The plasma surface processor consists of a plasma generator, a gas delivery pipeline and a plasma shower head. The plasma generator generates high-voltage high-frequency energy and generates low-temperature plasma in the activated and controlled glow discharge in the nozzle steel pipe. The plasma is sprayed on the surface of the workpiece, and when the plasma and the surface of the object processed, the object changes and chemical reactions are produced. The surface has been cleaned, and hydrocarbon contaminants, such as grease, auxiliary additives, etc., have been removed, or it has been roughened by etching, or a dense cross-linked layer has been formed, or oxygen-containing polar groups (hydroxyl, carboxyl) have been introduced. The agglomeration promotes adhesion of various coating materials and is optimized for bonding and paint applications. Under the same effect, the application of plasma treatment to the surface can obtain very thin high tension coating surface, which is beneficial to bonding, coating and printing. No strong action ingredients such as other machines, chemical treatments are required to increase adhesion.

Chemical Treatment

This method is no current action, the use of chemical interaction to form a plating layer on the surface of the workpiece. The main methods are:

Chemical conversion coating treatment

In the electrolyte solution, the metal workpiece has no external current, and the chemical substances in the solution interact with the workpiece to form a coating on its surface, which is called chemical conversion coating treatment. Such as bluing, phosphating, passivation, chromium salt treatment, etc. on the metal surface.

Electroless Plating

In the electrolyte solution, the surface of the workpiece is catalytically treated without external current. In the solution, due to the reduction of chemical substances, certain substances are deposited on the surface of the workpiece to form a coating process, which is called electroless plating, such as electroless nickel plating, Electroless copper plating, etc.

Thermal Processing Method

In this method, the material is melted or thermally diffused under high temperature conditions to form a coating on the surface of the workpiece. Its main methods are:

Hot dip plating

The process of placing a metal workpiece into molten metal to form a coating on its surface is called hot-dip plating, such as hot-dip galvanizing, hot-dip aluminizing, etc.

Thermal spray

The process of atomizing molten metal and spraying it on the surface of the workpiece to form a coating is called thermal spraying, such as thermal spraying zinc, thermal spraying aluminum, etc.

Hot stamping

The process of heating and pressing metal foil to cover the surface of the workpiece to form a coating layer is called hot stamping, such as hot stamping aluminum foil.

Chemical heat treatment

The process of contacting and heating the workpiece with chemical substances, and making a certain element enter the surface of the workpiece at a high temperature is called chemical heat treatment, such as nitriding, carburizing, etc.

Surfacing

By welding, the process of making the deposited metal accumulate on the surface of the workpiece to form a welding layer is called surfacing, such as surfacing wear-resistant alloys.

Vacuum Treatment

This method is a process in which materials are vaporized or ionized and deposited on the surface of the workpiece in a high vacuum state to form a coating. Its main method is.

Physical vapor deposition (PVD)

Under vacuum conditions, the metal is vaporized into atoms or molecules, or ionized into ions, and deposited directly on the surface of the workpiece to form a coating process, which is called physical vapor deposition. The deposition particle beam comes from non-chemical factors, such as evaporation sputtering, ion plating, etc.

Ion implantation

The process of implanting different ions into the surface of the workpiece under high voltage to modify the surface is called ion implantation, such as boron implantation.

Chemical vapor deposition (CVD)

Under low pressure (sometimes also normal pressure), the process in which gaseous substances form a solid deposition layer due to chemical reaction on the surface of the workpiece is called chemical vapor plating, such as vapor deposition of silicon oxide, silicon nitride, etc.

Other Methods

Mainly mechanical, chemical, electrochemical, physical methods. The main method of which are:

Painting

The process of applying paint (organic or inorganic) to the surface of the workpiece to form a coating is called painting, such as spray painting, brushing, etc.

Impact plating

The process of forming a coating layer on the surface of the workpiece by mechanical impact is called impact plating, such as impact galvanizing.

Laser surface treatment

The process of irradiating the surface of the workpiece with a laser to change its structure is called laser surface treatment, such as laser quenching, laser remelting, etc.

Super hard coating technology

The technology of preparing super hard film on the surface of the workpiece by physical or chemical methods is called super hard film technology. Such as diamond film, cubic boron nitride film and so on.

Electrophoresis and electrostatic spraying

(a) Electrophoresis

The workpiece is put into the conductive water-soluble or water-emulsified paint as an electrode to form a solution circuit with the other electrode in the paint. Under the action of the electric field, the coating solution has dissociated into charged resin ions, the cations move to the cathode, and the anions move to the anode. These charged resin ions, together with the adsorbed pigment particles, are electrophoresed to the surface of the workpiece to form a coating, a process called electrophoresis.

(b) Electrostatic spraying

Under the action of DC high voltage electric field, the atomized negatively charged paint particles are directed to fly to the positively charged workpiece to obtain a paint film, which is called static spraying.

.png)