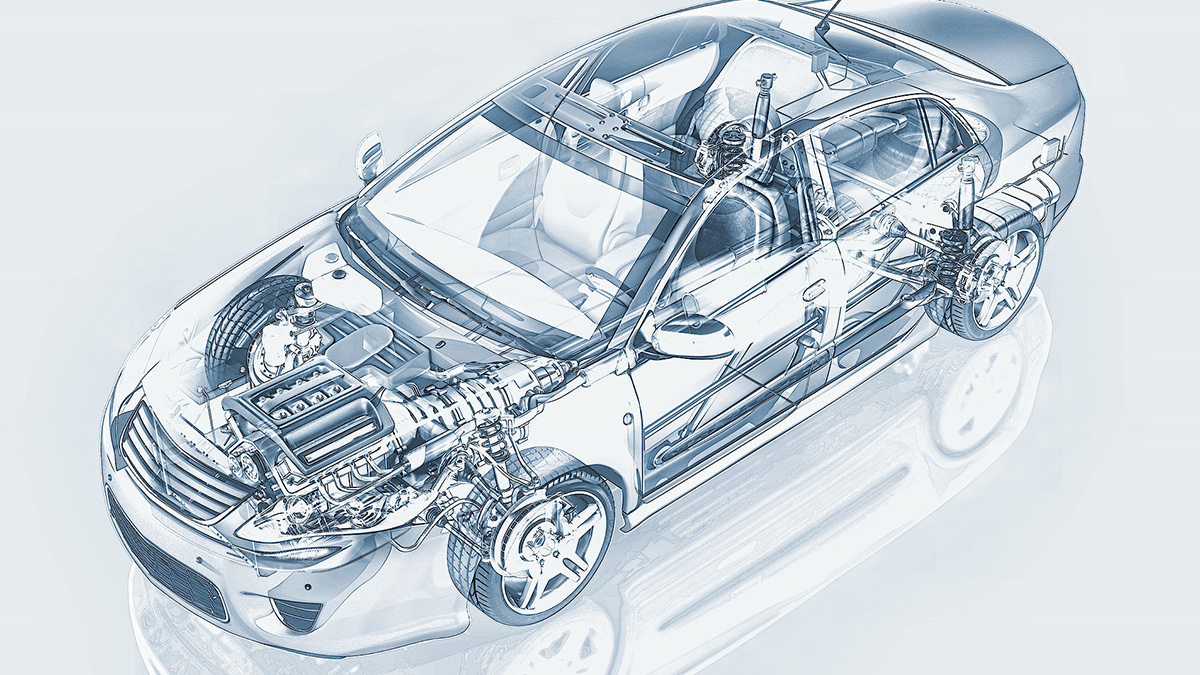

With the development of the electric vehicle market, the braking energy recovery system has received extensive attention, because driving distance can be extended through the braking energy recovery system.

During the deceleration and braking of traditional internal combustion engine vehicles, the energy of deceleration is converted into heat energy and released through the braking system. In electric vehicles and hybrid vehicles, this wasted energy can be converted into electrical energy through braking energy recovery technology, stored in the battery, and further converted into driving energy. The braking energy recovery system includes a generator, a battery, and an intelligent battery management system. With an Electromechanical Brake Servo (eBKV) system, the energy recovery system is coordinated with the mechanical braking system for vehicle braking.

Brake energy recovery system concept:

The braking system with braking energy recovery was developed for vehicles with three-phase current drives. Depending on the motor speed, the temperature of the high-voltage battery, and the charge level, the three-phase current drive can decelerate the vehicle in alternator mode. These factors fluctuate in electrical deceleration and may require hydraulic compensation. The alternation between electrical and hydraulic deceleration is called hybrid braking.

The electric drive system retrieves the electromotive energy released while braking. The three-phase current drive braking system controls the transfer of the generated energy to the high-voltage battery, where is stored for later use, thus increasing the cruising range of the electric vehicle.

The braking system includes:

Tandem master cylinder, wheel brakes, electromechanical brake booster, electronic stability control/anti-lock braking system (ESC/ABS), brake system accumulator, and three-phase current drive. The electromechanical brake booster increases the brake force applied by the driver to the brake petal.

The composition and working principle of eBKV:

When the driver operates the brake pedal, the push rod transmits the pedal actuation force through the piston rod to the tandem brake master cylinder. A brake pedal position sensor detects the force on the brake pedal and converts its value to a numerical amount. This value is sent from the brake pedal position sensor to the brake booster control unit. At the same time, the electromechanical brake booster detects the operating condition of the electric motor. This information indicating the operating condition of the engine comes from the engine (electric motor) position sensor of the electric motor/transmission unit. The brake booster control unit calculates the required increased braking force based on the driver's braking request combined with the motor condition information. The pinion shaft of the motor is engaged to allows the motor to supplement the braking force applied by the driver. The braking force applied to the brake petal can be amplified six-fold.

The composition and working principle of the accumulator:

The brake system accumulator stores brake fluid and directs it back into the brake system when needed. Its purpose is to reduce brake pressure. If the brake booster control unit detects insufficient alternator deceleration, the pressurized brake fluid in the accumulator is sent back into the brake system. A corresponding signal is sent from the brake booster control unit to the control unit of the pressure accumulator. If the alternator decelerates sufficiently, the hydraulic brake pressure on the wheel brakes is reduced. This is achieved by flow of brake fluid into the accumulator, as the piston in the brake accumulator is pushed back.

The working process of hybrid braking:

-

Deceleration request:

The driver depresses the brake pedal to slow the vehicle and bring it to a complete stop. The driver's braking request is communicated via the brake booster control unit using the brake pedal position.

-

Friction deceleration:

The driver's request to decelerate increases the pressure in the hydraulic brake system to reduce vehicle speed.

-

Energy recovery deceleration:

- Support for regenerative deceleration: The brake boost control unit receives information from the power and control electronics of the electric drive to determine if the three-phase current drive is capable of supporting the hydraulic braking system. This condition will be met when the vehicle is moving at high speed. Depending on the available alternator braking torque, the hydraulic brake pressure will remain unchanged or it will be decreased. As the vehicle speed decreases, the braking torque of the alternator increases. The hydraulic brake pressure on the wheels is then reduced according to the available alternator braking torque. For this purpose, the brake system accumulator draws in brake fluid to reduce the pressure in the hydraulic brake system. This means that only the braking torque of the alternator will be used for deceleration for a period of time.

- Insufficient support of three-phase current drive device: If the braking torque of the alternator decreases during deceleration, the brake booster control unit sends a signal to the control unit of the brake system accumulator. The accumulator then returns the stored brake fluid to the brake system, increasing the pressure in the hydraulic brake system. This also occurs when the vehicle brakes and comes to a complete stop. The alternator torque is discontinued when the vehicle speed is below 10 km/h. At this time, the vehicle is braked by hydraulic pressure alone.

-

Function backup mechanism:

- When the eBKV has a component failure (such as the controller, booster motor, sensor, etc.), resulting in no brake booster, the eBKV will light up a yellow or red brake warning light on the vehicle instrument panel. If the Electronic Stability Control (ESC) is still working normally and the driver brakes at this time, the ESC will activate the eBKV function to supplement the force the driver applies to the brake pedal.

- When the eBKV and ESC have functional failures at the same time, and there is no brake booster, the eBKV will, like a traditional vacuum booster, ensure that the mechanical device can still meet the 0.25g deceleration of the whole vehicle under the 500N pedal force required by the national standard.

.png)