Direct Energy Deposition (DED), also known as metal laser cladding, is one of the methods used to fabricate metal workpieces by additive manufacturing technology.

In recent years, various industries have developed many new types of processing technologies in response to the processing needs of the new era. Among them, laser-related processing technologies have been developed for welding, cutting, repairing, anti-wear coating, and laminate manufacturing. They have been widely used in engineering fields, including aerospace, automotive, shipbuilding, mold, and biomedical industries.

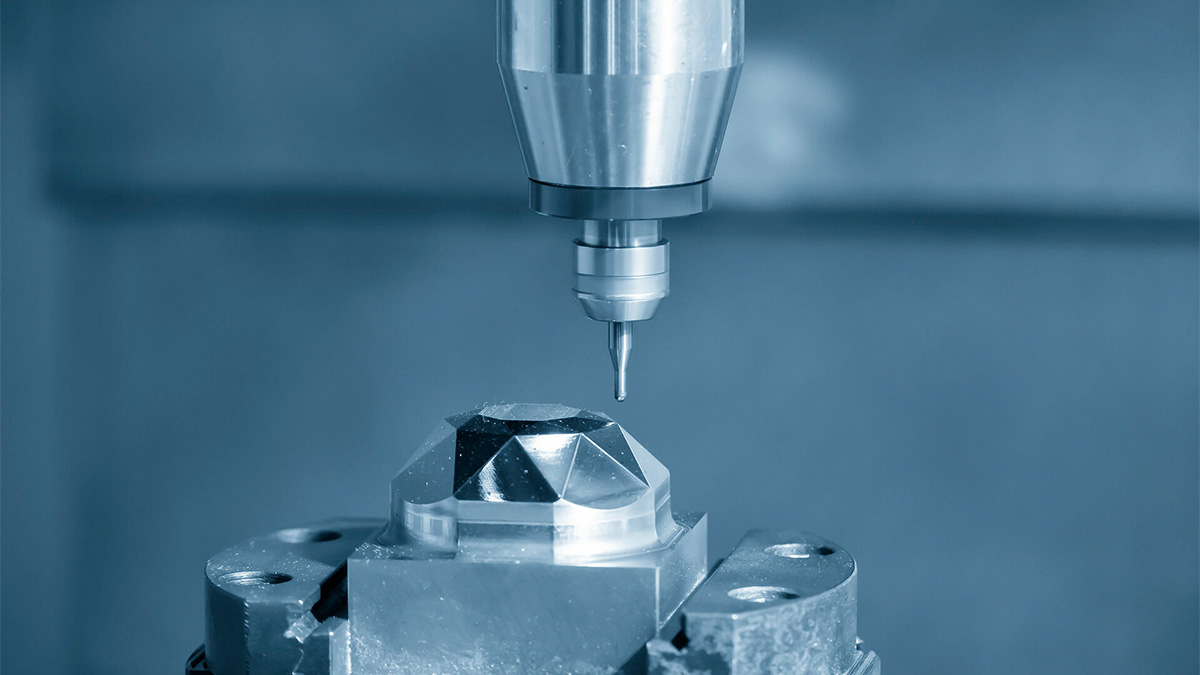

DED uses high-energy lasers to simultaneously heat powder particles in flight, and the surface of a substrate, to form a molten pool, which can be stacked in layers to form a three-dimensional shape.

This three-dimensional Laser Deposition technology is a form of laminated manufacturing technology. Laminated manufacturing technology is also known as 3D printing technology. 3D printing technology allows industries to produce complex metal components as 3D structures can be combined to form products with unique, practical, and aesthetic properties.

What is Direct Energy Deposition Technology (DED)?

During DED processing, material is directly fed into a high-temperature melting area in the form of powder or filament. The melted material is then deposited layer by layer onto a substrate. Laser direct energy deposition is an additive manufacturing process. 3D objects can be formed by continuous layer-by-layer fusion.

Direct laser deposition (DLD) technology can also be used to add coatings to three-dimensional objects by laser melting metal, alloy, or ceramic gold powder materials to the object. It has the advantages of rapid prototyping and can quickly produce large-scale coatings or components.

Direct Energy Deposition (DED) Technology Principle and Processing Method

- Machine technology:

DED machines can be equipped with independent controllers which control the machines through external input-output (IO) interfaces and programmable logic controllers (PLC) Integrating DED with man-machine interface control function can automate the cladding processing. The parameters of the DED machine are integrated and optimized, and then written into CAM software, so that the process parameters, microstructure, and mechanical properties can be predicted.

- Process molding technology:

This technology integrates and optimizes the process parameters of the DED machine, determines the setting value or range of each process parameter by regression analysis, and conducts a factor experiment for three significant control factors: laser power, scanning speed, and powder supply amount. Gas path optimization determines the best process parameters, and observe the results of each path covered by path planning. Finally, after optimization, the results are written into the CAM path planning software to improve the appearance, flatness, and mechanical properties of the finished product, and achieve the goal of predictable process parameters, microstructure, and mechanical properties.

If the workpiece can be integrated and designed, a workpiece that originally required many parts can be produced as a single part, which has a great advantage in reducing costs. So the future application of DED is promising.

What are the Technical Advantages of Direct Energy Deposition (DED)?

In direct laser deposition, material is melted and attached to a substrate, so the utilization rate of the material is low compared with the traditional machining production methods which may waste more than 50% of the material in the production process. Direct laser deposition is especially helpful to save on material costs in industries such as aerospace, semiconductor, LCD, mold, power generation, and biomedicals where materials and manufacturing costs can be very high. Repairs can be performed when components are partially damaged using small quantities of material so costs can be reduced.

Direct laser deposition equipment can be individually designed for customers to create customized systems. The mobile control system can be adjusted to suit the needs, including integrating with robots, or rotary tables, etc.

What is the Industrial Applicability of Direct Energy Deposition (DED)?

The applications of direct laser deposition technology can be divided into: 3D printing of new components, coating, and repairing the surface of components. When new components are manufactured by direct laser deposition 3D printing, a carrier substrate is required. After the 3D component is produced, the carrier can be cut off, or the carrier itself may be part of the component. Therefore, direct laser deposition technology can add 3D printed components or additional functions to existing components.

DED powder spraying technology has great potential for producing workpieces that require fine detail, such as aerospace, automobile, and other industries. DED can make very complex workpieces, and workpieces can be made of integrated parts, reducing the total number of parts required for a design. DED is very suitable to use with new alloy materials, especially materials such as gradient materials that are not easy to manufacture with by other methods, so DED technology has a promising future.

.jpg)

.png)