The global manufacturing industry is moving towards intelligent manufacturing, and Industry 4.0 is driving the manufacturing industry towards trends of higher efficiency, lower costs, and intelligent and flexible production. The nine technologies of Industry 4.0 include Big Data, Laminated Manufacturing, Cloud Technology, Automation, System Integration, Internet of Things, Cyber Security, Augmented Reality, and Simulation.

Indispensable technological manufacturing technologies in the transformation of Industry 4.0:

Today's manufacturing industry is undergoing a huge technological revolution. Industry 4.0 is orienting towards high production efficiency, cost reduction, and flexible and intelligent production. Future factory concepts will include the increased use of major technologies such as multi-layer manufacturing, big data, system integration, and automation. Various enterprises and R&D units have invested much in the research of multi-layer manufacturing technology, one of the core technologies. The concept of prototyping and mass production of tools is gradually being eliminated and is being replaced with rapid proofing. Design and manufacturing are entering an era of highly customized digital manufacturing technology.

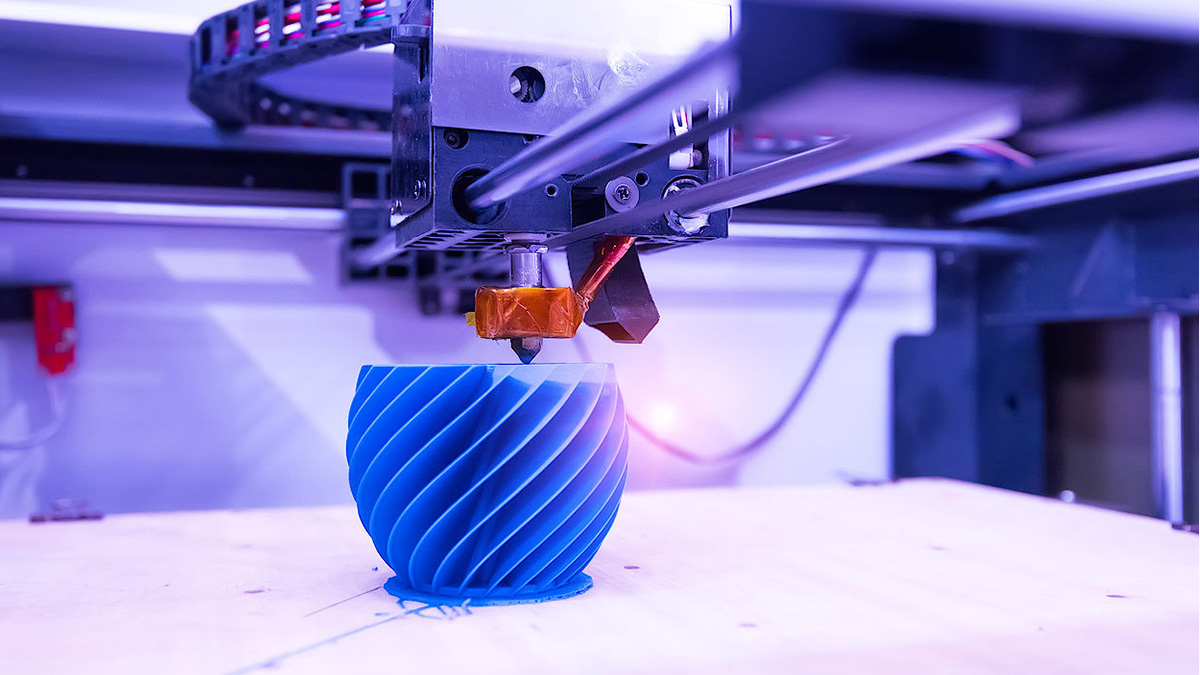

Among the nine major technologies of Industry 4.0, laminated manufacturing (also known as 3D printing) is regarded as the technology with the greatest potential to significantly change the manufacturing industry. The use of rapid proofing is gradually eliminating the prototyping of tools and is providing direct product realization. This has brought about new business models and product innovation capabilities. As technology matures, an era of high customization and digital manufacturing technology is taking place.

Metal laminated manufacturing is an additive form of manufacturing where objects with complex structures can be manufactured without the use of molds. Because of the high degree of design freedom, it is easier to develop applications which cannot be achieved by the use of traditional subtractive processes or plastic forming processes. Additive manufacturing can be used to make complex structural objects, special interior feature variations, and highly customized products which are lightweight and material saving.

In recent years, with the number of companies and individuals using laminate manufacturing to produce components and products increasing, innovative ideas have been introduced which have further stimulated growth in the industry. Laminated manufacturing is currently the technology most used. However due to material property restrictions, it is only suitable for proofing models and for forming structures that do not face safety considerations. Whether it is automotive, medical, food, aerospace, or even industrial, the demand for innovation in the metal lamination manufacturing industry has turned into a torrent, and is driving the development of high speed and high precision manufacturing.

From Product Design to Manufacturing-Analyzing the Current Situation of Metal Lamination Manufacturing

Metal lamination manufacturing technology has become important in the development of emerging industries, and the demand has grown year by year. It’s application areas include upstream design products, midstream equipment and material applications, downstream processing and manufacturing, and post-processing.

- Upstream - Product design: In product design, computer 3D programs will scan, reverse engineer and construct 3D drawings for products.

- Midstream - Equipment and material applications: Mainstream metal laminate manufacturing includes Binder Jetting (BJ), Powder Bed Fusion (PBF), and Directed Energy Deposition (DED); The materials used in metal laminate manufacturing include adhesives and metal powder (stainless steel alloy powder, titanium alloy powder, etc.).

- Downstream - Manufacturing, post-processing: After metal laminating, the parts undergo post-processing (cutting, polishing, surface treatment, etc.), and after post-processing, the surface is processed to meet the required appearance and size standards of the final product.

At present, traditional manufacturing technology methods include cutting, casting, and plastic formation. Due to technical limitations of traditional manufacturing processes, relatively complex products like turbine blade parts are difficult to form. These special lightweight structures can be manufactured faster and more conveniently using metal lamination production.

Metal build-up manufacturing technology evolution:

Since 1990, metal lamination manufacturing has flourished, and various processes have been developed. Selective laser melting (SLM) is the most widely used method in the market. In the aerospace or medical industry, mainstream factories have successfully produced highly specialized process equipment.

SLM is characterized by the ability to produce finished products with structural flexibility using a wide range of materials. Multiple irregular structures can be made using SLM processing, integrated molding, or a combination of the two. One-piece, large composite structures can be made with SLM that are not possible to make by other processes. If vigorously promoted, SLM will enable the industry to make break-throughs that will eliminate the bottlenecks of traditional processes, and further improve the integrity of this technology.

Metal Lamination Manufacturing Technology:

Metal lamination manufacturing mainly includes three molding technologies: Laser Powder Bed Fusion (LPBF), Binder Jetting printing (BJ), and Directional Energy Deposition (DED).

-

Laser Powder Bed Fusion Technology (LPBF):

Laser powder bed fusion technology is currently the most common forming method in metal lamination manufacturing. The laser is used as the energy source to scan and heat the flat powder. After the scanning is completed, the Z-axis of the platform drops to a certain thickness. Then the powder spreading device spreads the new powder on the platform, and the energy source scans a new layer. By repeating the above process, the three-dimensional object is gradually formed using the principle of lamination manufacturing. After the process, the loose powder that has not been scanned by the laser is removed to obtain the finished product.

-

Binder Jetting Technology (BJ):

The adhesive jet printing process uses two or more materials, with powder as the base, and the adhesive as the bond between the powder and the powder. Spread the powdered material in the construction task, and then use the inkjet head to spray the adhesive on the selected printing position, and then spread a new layer of powder. The printout is complete. The printed product of this technology needs to go through post-processing. The function of debinding is to remove the adhesive in the initial embryo; sintering is to combine the degreasing brown embryo into one, and after it is cooled and taken out, the metal printed product can be obtained.

-

Directed Energy Deposition Technology (DED):

DED technology mainly uses powder cladding to transport inert gas and metal powder coaxially, and deposit the powder in the high-temperature melting zone through laser or other energy sources. Its characteristic is that it is not limited by the size of the powder bed, and can make large-sized metal objects or make slender structures on curved workpieces. It is especially suited for the manufacture and repair of aerospace components.

Features of metal lamination manufacturing:

Due to its high degree of flexibility and reliability, metal lamination manufacturing has spread to many fields. The three mainstream metal laminate technologies have unique characteristics and are irreplaceable in many aspects.

-

Forming efficiency:

Among the three mainstream metal lamination manufacturing technologies, BJ is most suitable for mass production. The matrix nozzle can perform large-area graphic printing, and produce multiple molded objects at high speed. SLM has developed using laser co-forming technology that greatly reduces the molding time. DED technology manufacturing has not yet shown signs of significant improvement in shortening the processing time.

-

Mechanical behavior:

The performance of laminated parts is closely related to the density of the finished product. BJ needs to be formed by adhesives instead of directly melting the metal during the process. The finished product is affected by pores and it is difficult to achieve a high theoretical density; while LPBF and DED finished products use high-density energy to melt the metal powder. Deposition molding can reach more than 99% of the theoretical density and has high strength.

-

Forming size:

BJ formed items contain binders and require degreasing and sintering to obtain metal products. The need to complete degreasing and the high time costs, make it difficult to make thicker objects. LPBF needs to be processed in an inert gas atmosphere or vacuum, so the size of the finished product is limited by the size of the molding chamber. In contrast, the DED print head can output powder and protective gas at the same time, without the limitation of the powder bed mechanism, so can produce large objects.

Metal Lamination Manufacturing Applications:

-

Shorten manufacturing time:

Traditional metal processing methods are divided into the cutting method, molding method, and casting method. The metal cutting method is the most commonly used metal processing method. The main methods are turning, milling, planning, grinding, drilling, etc. Usually, it is necessary to cooperate with a specific special fixture to perform precise processing in a specific position. This method requires the production of a jig for smooth processing. The common molding methods include stamping, powder pressing, metal powder injection molding, and die casting. This method requires the production of complex molds to form. Generally, the mold production time is about 5 to 60 days, and the complex product structure even requires a longer manufacturing time to complete the mold manufacturing.

Common traditional casting methods include sand casting and lost wax casting. The characteristics of these casting methods are insufficient to provide the appearance characteristics required for many objects. Metal lamination manufacturing can eliminate the time required for jig and mold making, saving a large amount of production time.

-

Few in number:

When only one sample object is required, there is no need to manufacture mockups and molds. Because the cost of mockups and molds remains high, and take a large amount of time to produce, metal laminate manufacturing can greatly reduce this cost and save time.

-

Complex shape:

The complex shapes and structures are currently not possible to make with traditional, lattice structure, pour mold processing methods. Metal laminate manufacturing can completely overcome these challenges.

- One piece processing:

In the face of increasing environmental requirements, the one-piece molding process made possible with metal lamination manufacturing can greatly reduce material defects caused by traditional processing.

.png)