The worldwide manufacturing sector is shifting toward smart manufacturing, with Industry 4.0 leading the way by promoting greater efficiency, reduced costs, and intelligent, adaptable production processes. The nine key technologies of Industry 4.0 encompass Big Data, Layered Manufacturing, Cloud Technology, Automation, System Integration, Internet of Things, Cybersecurity, Augmented Reality, and Simulation.

Key Technological Advances in the Transition to Industry 4.0

The modern manufacturing industry is undergoing a significant technological revolution driven by Industry 4.0. This transformation is aimed at achieving higher production efficiency, cost reduction, and more flexible and intelligent production processes. Future factory concepts will prominently feature major technologies such as multi-layer manufacturing, big data, system integration, and automation. Numerous enterprises and research and development units have invested heavily in the exploration of multi-layer manufacturing technology, which stands as one of the core technologies driving this change. The traditional concept of prototyping and mass production of tools is gradually giving way to rapid proofing. This transition signifies that design and manufacturing are entering an era of highly customized digital manufacturing technology.

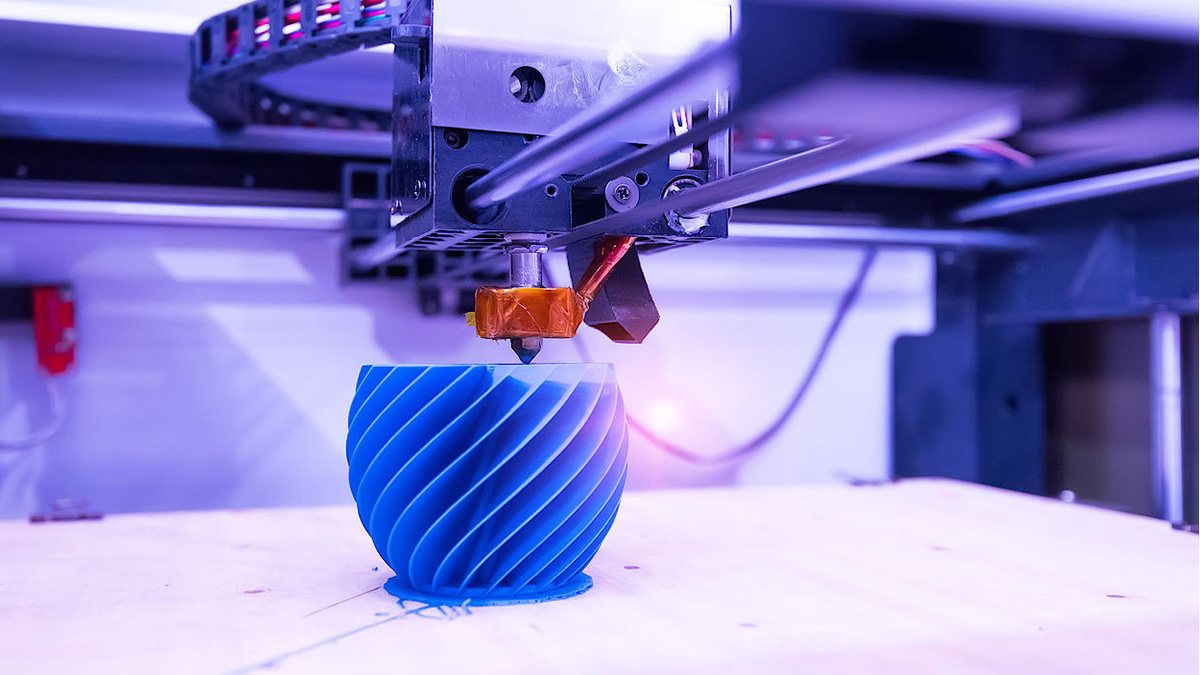

Among the nine major technologies associated with Industry 4.0, laminated manufacturing, often referred to as 3D printing, is considered to have the greatest potential to profoundly alter the manufacturing landscape. Rapid proofing is progressively replacing the conventional practice of tool prototyping, offering direct product realization. This shift has ushered in new business models and product innovation capabilities. As this technology matures, we are witnessing the advent of an era characterized by high customization and digital manufacturing technology.

Metal laminated manufacturing represents an additive approach to manufacturing, enabling the creation of complex structures without the need for molds. The high degree of design freedom makes it easier to develop applications that were previously unattainable using traditional subtractive or plastic forming processes. Additive manufacturing facilitates the production of intricate structural components, unique interior features, and highly customized, lightweight, and material-efficient products.

In recent years, the increasing number of companies and individuals adopting laminated manufacturing for component and product production has sparked innovative ideas, further fueling industry growth. Currently, laminated manufacturing is the most widely employed technology. However, owing to material limitations, it remains primarily suitable for proofing models and for creating structures with no safety constraints. The demand for innovation in the metal laminated manufacturing industry has surged across various sectors, including automotive, medical, food, aerospace, and industrial, driving the development of high-speed, high-precision manufacturing.

From Product Design to Manufacturing: Analyzing the Current State of Metal Laminated Manufacturing

Metal laminated manufacturing technology has become increasingly crucial in emerging industries, experiencing year-on-year growth in demand. Its application areas span the entire production cycle, including product design, equipment and material applications, manufacturing, and post-processing.

- Upstream - Product design: In product design, computer 3D programs scan, reverse-engineer, and create 3D drawings for products.

- Midstream - Equipment and material applications: Mainstream metal laminated manufacturing methods include Binder Jetting (BJ), Powder Bed Fusion (PBF), and Directed Energy Deposition (DED). Materials employed in metal laminated manufacturing encompass adhesives and metal powders, including stainless steel alloy powder and titanium alloy powder, among others.

- Downstream - Manufacturing, post-processing: Following metal lamination, parts undergo post-processing, involving cutting, polishing, surface treatments, and more. Post-processing ensures that the surface meets the required appearance and size standards for the final product.

Currently, traditional manufacturing methods encompass cutting, casting, and plastic forming. Due to the technical limitations of these traditional processes, the production of relatively complex products like turbine blade parts poses significant challenges. Metal laminated manufacturing offers a faster and more convenient solution for the creation of these special lightweight structures.

Evolution of Metal Laminated Manufacturing Technology:

Since 1990, metal laminated manufacturing has experienced considerable growth, with various processes being developed. Selective laser melting (SLM) stands as the most widely adopted method in the market. In the aerospace and medical industries, mainstream manufacturers have successfully produced highly specialized processing equipment.

SLM is distinguished by its ability to create finished products with structural flexibility, utilizing a broad range of materials. SLM processing enables the production of complex, irregular structures, combining molding and integrated techniques. This approach allows for the creation of single-piece, large composite structures that are otherwise unattainable with alternative methods. By aggressively promoting SLM, the industry can overcome traditional process limitations, further enhancing the technology's integrity.

Metal Laminated Manufacturing Technology:

Metal laminated manufacturing primarily comprises three molding technologies: Laser Powder Bed Fusion (LPBF), Binder Jetting printing (BJ), and Directed Energy Deposition (DED).

-

Laser Powder Bed Fusion Technology (LPBF):

Laser powder bed fusion is presently the most common metal laminated manufacturing method. It employs a laser as an energy source to scan and heat flat powder. After each scanning pass, the platform's Z-axis drops by a specific thickness. A powder spreading device then distributes fresh powder on the platform, and the energy source scans a new layer. By repeating this process, three-dimensional objects are incrementally constructed using laminated manufacturing principles. Post-processing involves removing any loose powder untouched by the laser to obtain the finished product.

-

Binder Jetting Technology (BJ):

The adhesive jet printing process utilizes two or more materials, with powder serving as the base and adhesive acting as the binding agent between powder particles. The powdered material is spread in the construction task, and the inkjet head applies adhesive to the selected printing positions before applying a new layer of powder. The printed product requires post-processing, including debinding to remove the initial adhesive and sintering to fuse the degreased brown embryo into a solid metal printed product.

-

Directed Energy Deposition Technology (DED):

DED technology primarily utilizes powder cladding to transport inert gas and metal powder coaxially, depositing the powder into a high-temperature melting zone via a laser or other energy sources. DED technology is not limited by the size of the powder bed and can create large-sized metal objects or intricate structures on curved workpieces. It is particularly suitable for the manufacture and repair of aerospace components.

Features of Metal Laminated Manufacturing

Due to its high degree of flexibility and reliability, metal laminated manufacturing has found applications in a wide range of fields. The three mainstream metal laminated technologies possess unique characteristics, making them indispensable in various respects.

-

Efficiency of Formation:

Among the three mainstream metal laminated manufacturing technologies, BJ is most suitable for mass production. The matrix nozzle allows large-scale graphic printing, enabling the rapid production of multiple molded objects. SLM has advanced through the use of laser co-forming technology, significantly reducing the molding time. DED technology manufacturing has yet to show substantial improvements in shortening processing time.

-

Mechanical Behavior:

The performance of laminated components is closely linked to the density of the finished product. BJ relies on adhesives rather than direct metal melting, resulting in finished products that are affected by pores and struggle to achieve high theoretical density. In contrast, finished products produced using LPBF and DED use high-density energy to melt metal powders. Deposition molding can achieve over 99% of the theoretical density, ensuring high strength.

-

Formation Size:

BJ-formed items contain binders and require degreasing and sintering to obtain metal products. The need for degreasing and the time-consuming nature of this process limit the production of thicker objects. LPBF requires processing in an inert gas atmosphere or vacuum, constraining the size of the finished product by the molding chamber's dimensions. In contrast, the DED print head can simultaneously dispense powder and protective gas, eliminating the powder bed mechanism's constraints and enabling the production of large objects.

Applications of Metal Laminated Manufacturing

-

Reducing Manufacturing Time:

Traditional metal processing methods encompass cutting, molding, and casting. Cutting methods involve various precision machining techniques, often requiring specialized fixtures for precise processing. Molding methods, including stamping, powder pressing, metal powder injection molding, and die casting, necessitate the production of intricate molds. Mold production can take anywhere from 5 to 60 days, with more complex product structures requiring even longer. Traditional casting methods such as sand casting and lost wax casting have limitations in achieving the appearance characteristics required for many objects. Metal laminated manufacturing eliminates the need for jig and mold production, resulting in significant time savings.

-

Small-Batch Production:

When only a single sample object is required, there is no need for prototype and mold production. Given the high costs and time associated with prototype and mold creation, metal laminated manufacturing substantially reduces expenses and production time.

-

Complex Geometries:

Complex shapes and structures that are often unachievable through traditional lattice structures or mold processing methods can be realized through metal laminated manufacturing.

-

Single-Piece Processing:

In light of increasing environmental regulations, the single-piece molding process enabled by metal laminated manufacturing significantly reduces material defects resulting from traditional processing methods.

.png)