When we lightly press the accelerator and enjoy a smooth drive, there’s an invisible hero quietly at work behind the scenes: the CNC machine crafting every precise engine component. For consumers, fuel-efficient cars are often the top choice. For manufacturers, fuel efficiency is a critical factor that defines product competitiveness. Yet few realize that the journey toward efficiency doesn’t start at the gas pump—it begins with the machines that shape every micron of the engine. CNC machines are the unsung heroes making it all possible.

Micron-Level Precision: The Key to Every Kilometer

Traditional manufacturing methods often result in larger tolerances, causing excessive friction, poor sealing, or uneven weight distribution among engine components, which reduces both performance and fuel efficiency. Advanced CNC machines, however, translate design ideals into real-world performance with unparalleled precision.

High-end CNC machines can consistently achieve tolerances of ±0.001 inch (≈±25 microns) or better, ensuring nearly perfect fitment of critical components. This precision minimizes energy loss from friction or leakage. Coupled with real-time thermal compensation and high-performance cutting tools—such as carbide or coated tools—these machines maintain micron-level stability while improving surface quality, further reducing friction and energy waste.

When combined with Abradable Powder Coatings (APC), the coating gradually wears during initial operation to achieve an ideal shape, forming ultra-precise contact surfaces that reduce gaps, lower friction, and enhance sealing and operational efficiency.

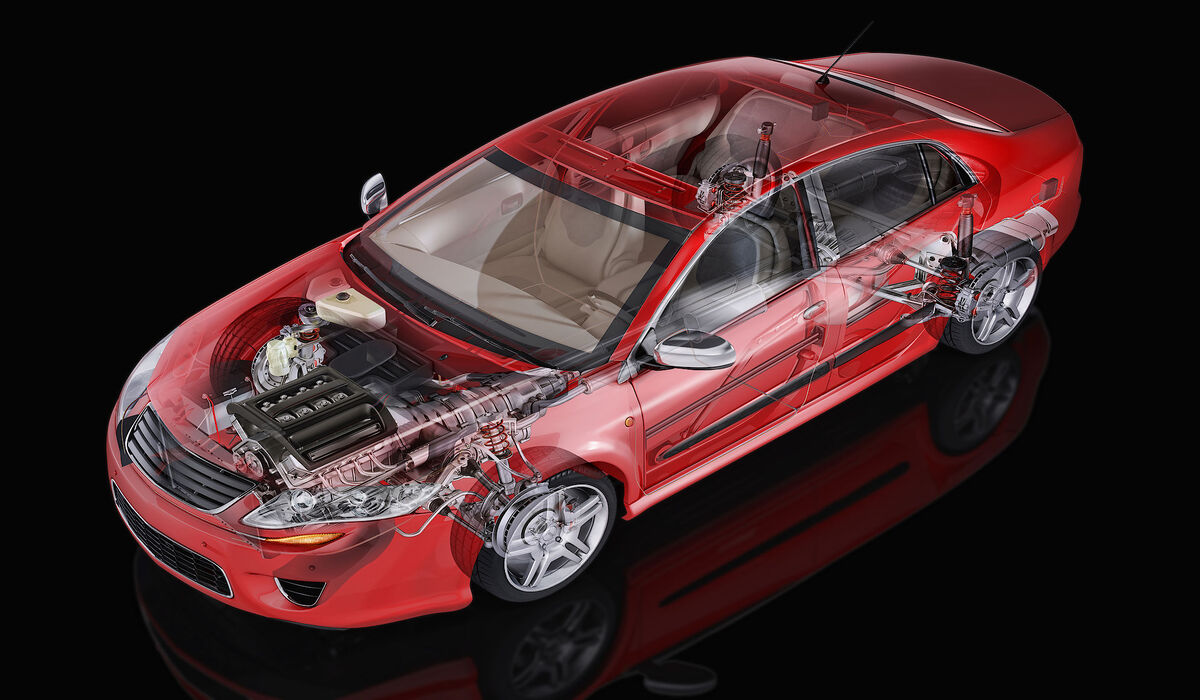

How CNC Machines Build High-Performance Engines

The engine block and cylinder head serve as the “heart” of the engine. CNC machines can precisely finish cylinder walls, ensuring true roundness and optimal surface texture, allowing pistons to move smoothly and fuel to burn more completely.

The crankshaft and camshaft act as the “nervous system” of power output. CNC machining can create their complex geometries with exacting accuracy, maintaining dynamic balance and synchronization, which reduces vibration and energy loss.

The fuel injection system is the “spark” of combustion. CNC-precision nozzles control atomization and spray angles accurately, ensuring that every drop of fuel mixes thoroughly with air for complete combustion.

All these technical details ultimately translate into a smoother driving experience and lower fuel costs for the driver.

Conclusion

In today’s environment of stricter industry standards and rising consumer expectations for performance and eco-friendliness, manufacturers must treat CNC machines as a strategic investment—not merely production equipment. Advanced CNC machining allows companies to produce high-performance, competitive engines while directly addressing the market demand for “fuel efficiency” and “eco-friendliness.” Simply put, companies that master micron-level machining are the ones shaping the future of the automotive engine market.

.jpg)

.png)