The primary advantage provided by various types of CNC machine tools is enhanced automation, as it allows for the reduction or elimination of operator intervention in the production of workpieces.

The advantage of many CNC machines is their ability to operate unattended throughout the entire machining cycle, providing the operator with the freedom to engage in other tasks. This not only reduces operator fatigue but also minimizes errors resulting from operational mistakes. Additionally, it ensures a consistent and predictable machining time for each workpiece. As the machine operates under program control, the skill level required of the CNC operator is lower compared to a machinist using conventional machine tools.

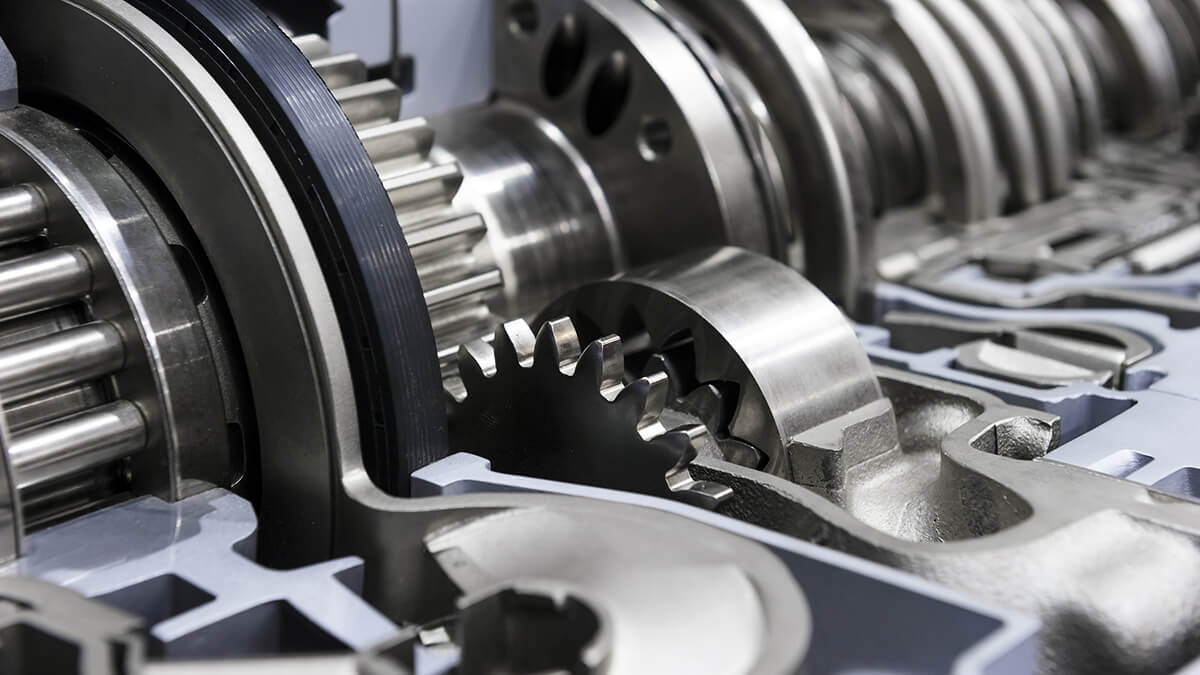

At the core of CNC functionality lies motion control—a fundamental and essential aspect. All types of CNC equipment feature two or more axes for precise and automatic positioning along their respective lengths of travel. Unlike conventional machines that rely on manual cranks and handwheels for motion, CNC machines utilize servomotors controlled by the CNC and guided by the part program. This allows for programmable motion types, such as rapid, linear, and circular, specifying the axes to move, the extent of motion, and the feed rate, in almost all CNC machine tools.

The execution of a CNC command involves the control system instructing the drive motor through a program to rotate a precise number of times. The rotation of the drive motor, in turn, moves the ballscrew, which drives the linear axis. A feedback device at the opposite end of the ballscrew confirms the completion of the commanded rotations, ensuring precision.

While a simple analogy to a table vise's linear motion helps illustrate the concept, the precision of a CNC machine's linear axis is far superior. The number of revolutions of the axis drive motor precisely dictates the amount of linear motion along the axis.

Understanding the programmable motion directions (axes) is crucial for CNC programmers. The axis names vary between machine tool types and are denoted by letter addresses, with common names like X, Y, Z, U, V, and W for linear axes, and A, B, and C for rotary axes. Programs consist of commands, and commands consist of words, each with a letter address and a numerical value. CNC control manufacturers may differ in how they determine word names, requiring reference to the manufacturer's programming manual for clarity.

A brief list of some common word types includes:

- O: Program number (used for program identification)

- N: Sequence number (used for line identification)

- G: Preparatory function

- X, Y, Z: Linear axis designations

- R: Radius designation

- F: Feedrate designation

- S: Spindle speed designation

- H: Tool length offset designation

- D: Tool radius offset designation

- T: Tool designation

- M: Miscellaneous function

Rotary axis departures also require a letter address (usually A, B, or C) along with the endpoint specified in degrees.

The three most basic motion types in CNC machines are:

Rapid Motion (Positioning): Used to command the machine's fastest possible rate, minimizing non-productive time during the machining cycle. Common applications include positioning the tool to and from cutting positions, moving to clear clamps and obstructions, and any non-cutting motion during the program.

Straight Line Motion: Enables the programmer to command perfectly straight line movements, as discussed in linear interpolation. This motion type allows the specification of the motion rate (feed rate) during the movement and can be employed for straight cutting movements, such as drilling, turning straight diameters, faces or tapers, and milling straight surfaces.

Circular Motion: Causes the machine to move in a circular path, generating radii during machining. This motion type, discussed in circular interpolation, maintains feed rate considerations made in straight-line motion.

.jpg)

.png)