The indexing plate is mainly used for milling machines, but also commonly used for drilling machines and surface grinders. It can be used for index drilling or milling, circumferential cutting, circumferential surface machining, straight line machining of planes and part of line segments.

The indexing plate is a graduated circular plate or one with circular rows of holes differently spaced that is used in machines as for graduating circles or cutting gear teeth.

It is one of the main auxiliary files on the machine tool. It clamps the workpiece on the chuck or between the two centers, and makes it rotate, index and position the machine tool auxiliary file. It can be used for index drilling or milling, circumferential cutting, circumferential surface machining, straight line machining of planes and part of line segments on the machine tool. It can be used in other mechanical equipment such as rotary tapping machines and indexing tapping machines. So, it is suitable for machine tool industry and other industries.

According to its transmission and indexing form, it can be divided into worm pair indexing plate, dial indexing plate, hole plate indexing plate, groove plate indexing plate, end tooth plate indexing plate and other indexing plates (including inductance indexing plate) and grating indexing discs).

According to its function, it can be divided into universal indexing plate, semi-universal indexing plate and equal indexing plate.

According to its structural form, there are vertical and horizontal indexing plates, tiltable indexing plates, and cantilevered indexing plates.

As a general-purpose machine tool accessory attachment, the indexing plate is mainly composed of a clamping part, an indexing and positioning part, and a transmission part. The indexing plate is mainly used for milling machines, but also commonly used for drilling machines and surface grinders. It can also be placed on the platform for the fitter to draw lines. There are two main types of indexing discs: general indexing head and optical indexing head.

General Indexing Plate

According to the indexing method and function, it can be divided into 3 types:

Universal indexing plate

the most widely used. The main axis can be tilted at any angle between horizontal and vertical. The indexing mechanism consists of an indexing plate and a worm-worm gear pair with a transmission ratio of 1:40 (see worm drive). Rotate the handle connected to the worm to insert the positioning pin into the selected positioning hole to achieve indexing. When the number of equally divided holes on the indexing plate cannot meet the indexing requirements, the transmission ratio can be changed through the exchange gear between the

worm gear and the main shaft to expand the indexing range. On the milling machine, the exchange gear of the universal indexing plate can be connected with the feed screw of the milling machine table, so that the axial feed of the workpiece and the rotary motion can be combined, and the spiral groove can be milled according to a certain lead;

Semi-universal indexing plate

The structure is basically the same as that of the universal indexing head, but without the exchange gear mechanism, the indexing plate can only be used for direct indexing, and cannot be linked with the milling machine table;

Dividing plate

Generally, a dividing plate with 24 slots or holes is used to directly realize the dividing of 2, 3, 4, 6, 8, 12, and 24 equal parts. There are horizontal, vertical and vertical-horizontal types. 3 types. The vertical-horizontal base has two mutually perpendicular mounting surfaces, and the spindle can be in a horizontal or vertical position. The indexing accuracy of the universal indexing plate is generally ±60".

Optical Indexing Plate

The main shaft is equipped with a precise glass dial or a circular grating, which is subdivided and enlarged by an optical or photoelectric system, and then the angle value is read out by the eyepiece, light screen or digital display device. The indexing accuracy can reach ±1", and the optical indexing plate is used for precision machining and angle measurement.

CNC Indexing Plate

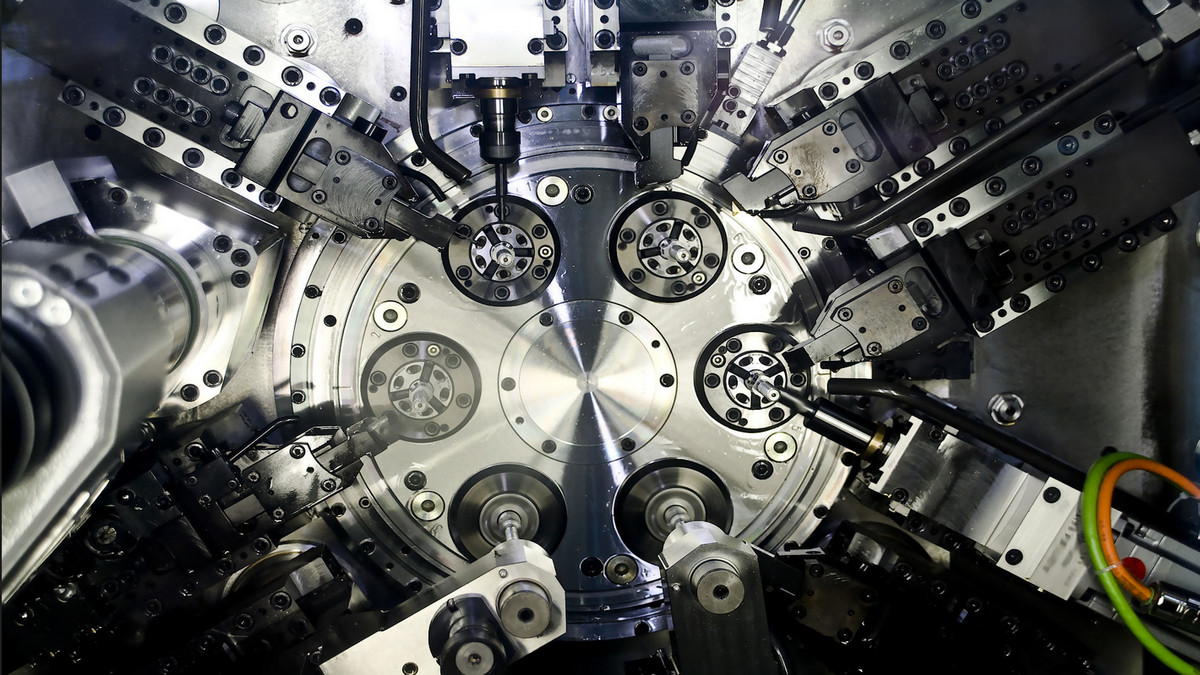

The CNC indexing plate is driven by an AC or DC servo motor, driven by a multi-pitch worm and worm gear mechanism, using a hydraulic embracing locking device, coupled with a solid rigid sealing structure.

CNC indexing discs are widely used in milling machines, drilling machines and machining centers. With the four-axis operation interface of the mother machine, simultaneous four-axis machining can be performed.

The combination of CNC indexing plate and spark machine can be used for bicycle and automobile tire mold processing.

The CNC indexing plate can also be combined with the DC/AC single-axis servo controller to connect to the M-signal for equal division processing.

What is the Importance of Indexing?

Indexing helps to locate the position of the specific document in files at a short period of time. It helps to make a quick decision by providing necessary information stored in files. Therefore, indexing is very important to save time and effort.