MCUs (microcontroller units) have a wide range of terminal applications, including home appliance controls, automotive electronics, education and entertainment, medical equipment, etc. Among them, automotive electronics and the Internet of Things are the main driving forces of the MCU industry.

Consumers in the automotive market desire convenience, safety, and energy-savings. These expectations represent some of the increasing requirements for intelligent and energy-saving automobiles, and are a driving force in the research and development of automotive electronic technology. Major car manufacturers are focusing more on automotive electronics, and the proportion of automotive electronics costs of automobiles has risen from 2 to 3% in the 1980s to now making up to as much as 40 to 50% of the overall cost.

Consumers in the automotive market desire convenience, safety, and energy-savings. These expectations represent some of the increasing requirements for intelligent and energy-saving automobiles, and are a driving force in the research and development of automotive electronic technology. Major car manufacturers are focusing more on automotive electronics, and the proportion of automotive electronics costs of automobiles has risen from 2 to 3% in the 1980s to now making up to as much as 40 to 50% of the overall cost.

Secondly, intelligent safety features can enhance the safety performance of the vehicle. Safety control operations are mainly divided into three processes: data acquisition, data processing, and sending of instructions to the driver.

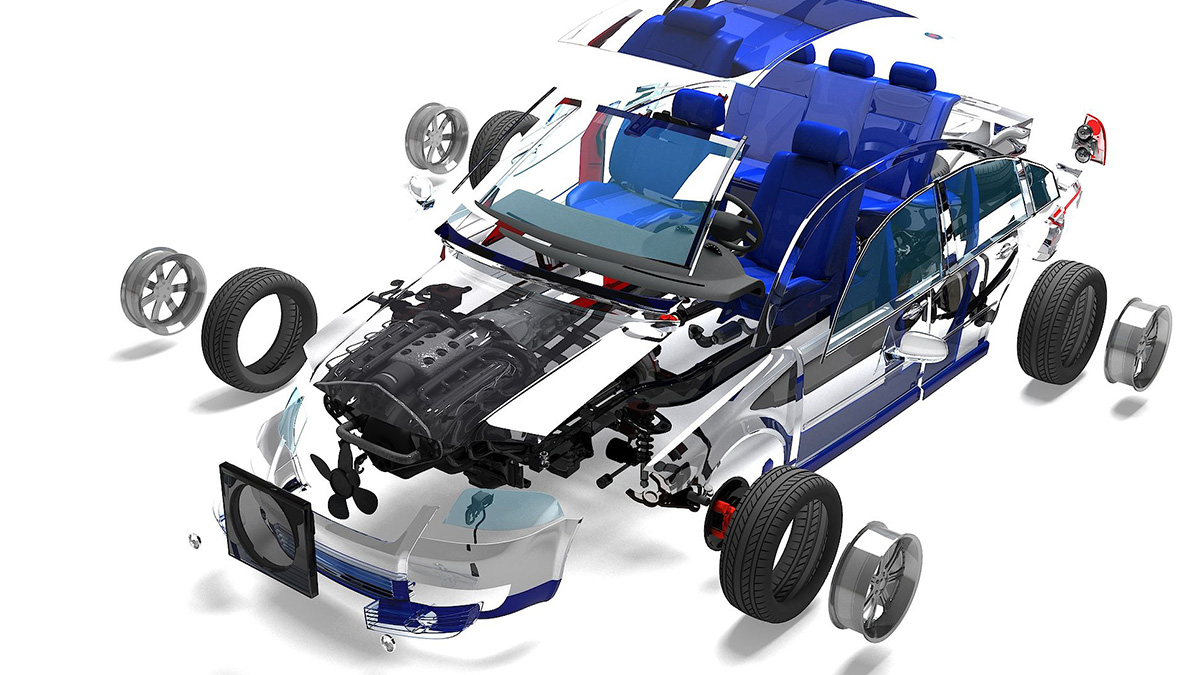

Entertainment, convenience, and safety features all require that the car be able to detect the environment, analyze the information, and make appropriate, efficient and accurate responses. All processes are completed by automotive electronics throughout systems, of which ECUs, (Electronic Controller Unit) MCUs, and sensors are the most important elements. All these components require semiconductors to function.

Automotive semiconductor key components:

- ECU: Electronic Control Unit

The first step in understanding automotive electronics is to understand the (ECU). Almost every automotive electronic system has an ECU as its core. An ECU is like an embedded computer which is used to control the major systems of the car. The ECU internal components include a microcontroller (MCU), input and output devices, circuits, AD (analog and digital) conversion circuits, power supply components, in-vehicle communication circuits, etc. As the complexity of the various control systems in the car increases, the number of ECUs in the car also increases. At present, there are hundreds of ECUs on some high-end model cars.

-

MCU:

Microcontrollers (MCUs) are most often used in consumer electronics, with the second-largest application being in automotive electronics. The most important task of the MCU in an ECU is to integrate of the central processing unit (CPU), memory, various input/output interfaces, timer/counter (timer/counter) etc. into one IC. The MCU is divided into four grades according to the bandwidth of the internal data bus: 4-bit, 8-bit, 16-bit, and 32-bit. Due to the complexity of application fields, different grades of MCUs are applicable. Simple functional systems, such as car air conditioners, windows, rear mirrors, etc., can use low-cost 8-bit MCUs. Brakes, airbags, and body stability controls that require high computing/processing capabilities use 16-bit MCUs. As automotive electronics moves towards greater intelligence, 32-bit is becoming more mainstream for components such as multimedia and entertainment devices, as well as driving control and other higher-end electronic information operations.

Besides being used in automotive electronics, 32-bit MCUs are used in the power system of the car to control the fuel ignition system. By increasing the accuracy of fuel injection and combustion control, fuel efficiency can be improved. 8-bit systems can no longer keep up with the processing speed requirements of fuel systems to meet modern environmental regulations. Hybrid engines and electronic vehicles also have high requirements for voltage control and electric recharge current control. When you step on the accelerator, because the system is controlled by electronics instead of traditional hydraulics, the power feedback requires extremely precise communication between systems to provide sufficient control. In hybrid or battery-powered vehicles, the battery not only powers the engine, but also powers the surrounding sensor subsystems. Interaction and feedback between the subsystems and the main system require the support of high-performance architecture.

-

Sensor:

The ECU / MCU of automotive electronics is responsible for data processing operations, and control of the various sensors responsible for collecting data. Driver assistance systems use image sensors, millimeter-wave radars, laser radars, acceleration sensors, angular velocity sensors, wheel speed sensors, tire pressure sensors, etc. These sensors are becoming more and more advanced, necessitating more advanced control systems.

With the advancement of imaging technology, and the improvement of system integration capabilities of car manufacturers, the information from multiple image sensors distributed inside and outside the vehicle, can make up for the lack of human vision and assist driving and improve safety. For example, single systems such as lane departure warning systems, parking assist systems, blind-spot detection systems, and reversing warning can protect the safety of the driver. By further integrating these systems, a more comprehensive system can be constructed to give a safe and comfortable driving experience. The development of autonomous driving technology is constantly improving.

Ability to adapt to the environment:

In addition to the functional development and processing capabilities of key components that must keep pace with applications, automotive semiconductors must face more challenges in the operating environment than general consumer electronics or even industrial semiconductors. Vehicles must adapt to the climate environment of different countries and take into account long-term mobility and safety. Therefore, in addition to the low environmental requirements of IC components installed inside the body of the vehicle, other automotive electronic components must be designed to operate in harsh environments. Tolerable ambient temperature requirements for general ICs are at most minus 10°C to 70°C, but the requirements for automotive electronics are from minus 40°C to 155°C, with more than 1,000 cycles being required. In addition to moisture resistance, the requirements for high-temperature resistance, shock resistance, and failure rate are much stricter than those of general consumer electronic parts. Coupled with the long service life of the car, operating life and durability are also severely tested, and the supply life of parts must exceed 30 years.

Efficiency, decreased power consumption, and integration are the main technology development trends

At present, the mainstream design of MCUs includes three major trends: high performance, low power consumption, and high integration. In terms of high performance, 32-bit MCUs have become mainstream, especially in recent years. With the accelerated speeds of the Internet of Things, 32-bit MCUs have rapidly become popular. The price difference between 8-bit and 32-bit MCUs has gradually narrowed. Computing speed performance has reached 100MHz and above, and performance has also improved. The cores of 32-bit MCUs are mostly ARM Cortex-M4 to M7, which can support DSP and single-precision floating-point operation instructions. The clock operation frequency can also reach 400MHz, which is quite suitable for the Internet of Things with edge computing design.

Another trend is towards lower power consumption. Although low power consumption has always been a focus of MCU design, in the era of the Internet of Things, this feature will be further strengthened, especially for mobile devices that rely on battery power, where low power consumption is essential.

The first step in the operation of the IoT architecture is to gather the signals transmitted by a large number of low-level devices. These low-level devices are often scattered over a wide areas where power cable connection is not possible. Due to their large numbers, it is impossible to continually replace batteries, so low-power design is inevitable. For these types of applications, most manufacturers have proposed ultra-low-power MCU products, so that each product devise and its sensing node can maintain long-term operation.

Due to the diverse functions of the Internet of Things, to achieve high-integration, a single device must integrate as much hardware and software as possible. In addition to improving the performance of systems, manufacturers must continually reduce total material costs to remain competitive. At present, MCUs are integrating common technologies including the I/O interface, UART, USB, Ethernet, etc.

In the past, encryption and decryption were mainly calculated using software, but this process lengthens the response time of the system and increase the power required for computing. Existing manufacturers now design the hardware to perform this function. This not only speeds up the computing process and reduces power consumption, but also improves security, making it more difficult to crack the encryption.

As good communication is one of the most important requirements in IoT systems, advancements in wireless technology are also being developed. In the past, the MCU was used in conjunction with a wireless communication module. Recently, manufacturers have launched system-on-chip (SoC) which integrates the two. This important product strategy will help manufacturers increase user acceptance of the Internet of Things. With the gradual expansion of the market, more and more product types with improved functions will be developed.

The Internet of Things is undoubtedly the most important growth driver for MCU development. This trend not only drives market growth but also forces MCU technology to continually make breakthroughs. Combining high performance, low power consumption, and high integration will be the most important design focus of MCUs.

Taiwan's auto industry has long been biased towards back-end manufacturing and assembly, and there has been little in-depth discussion on front-end system design. However, with some auto industries becoming fully autonomous, vehicle intelligence has become a focus of development. Taiwanese companies are investing far more than before in system integration systems, from front-end chips to back-end software, and are developing automotive technologies to meet future trends. With the acceleration of the demand for intelligent systems, the demand for MCUs will continue to rise in the future.

.jpg)

.png)