- Showing results for

- Machine Tools

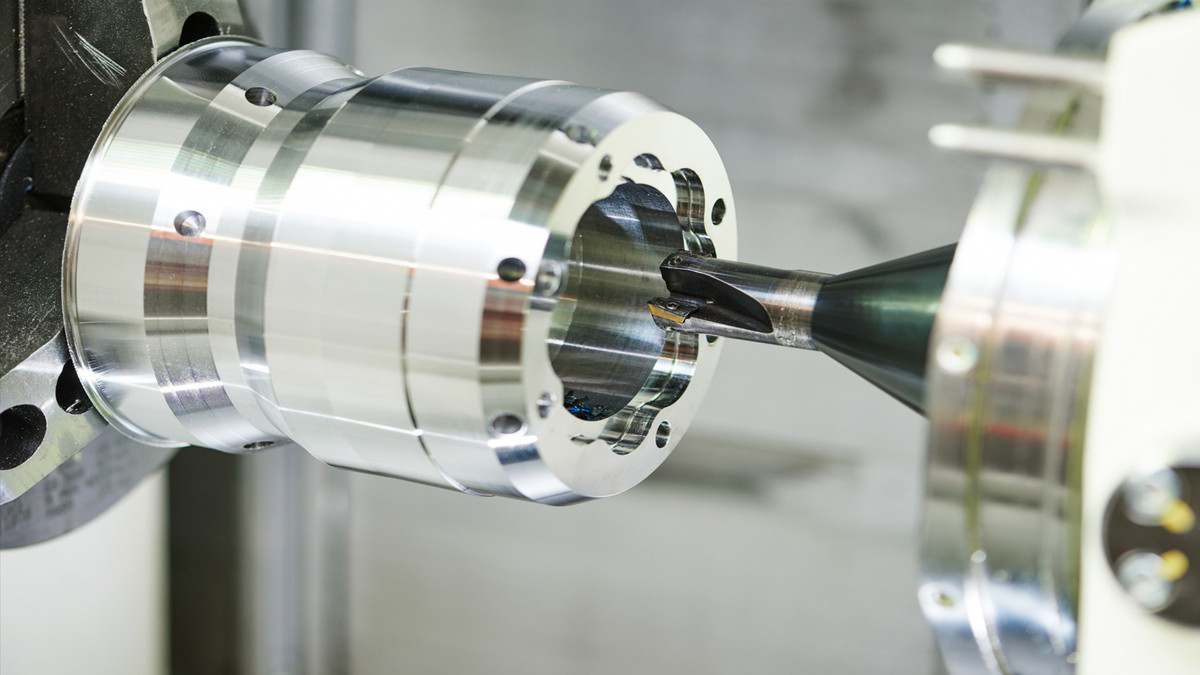

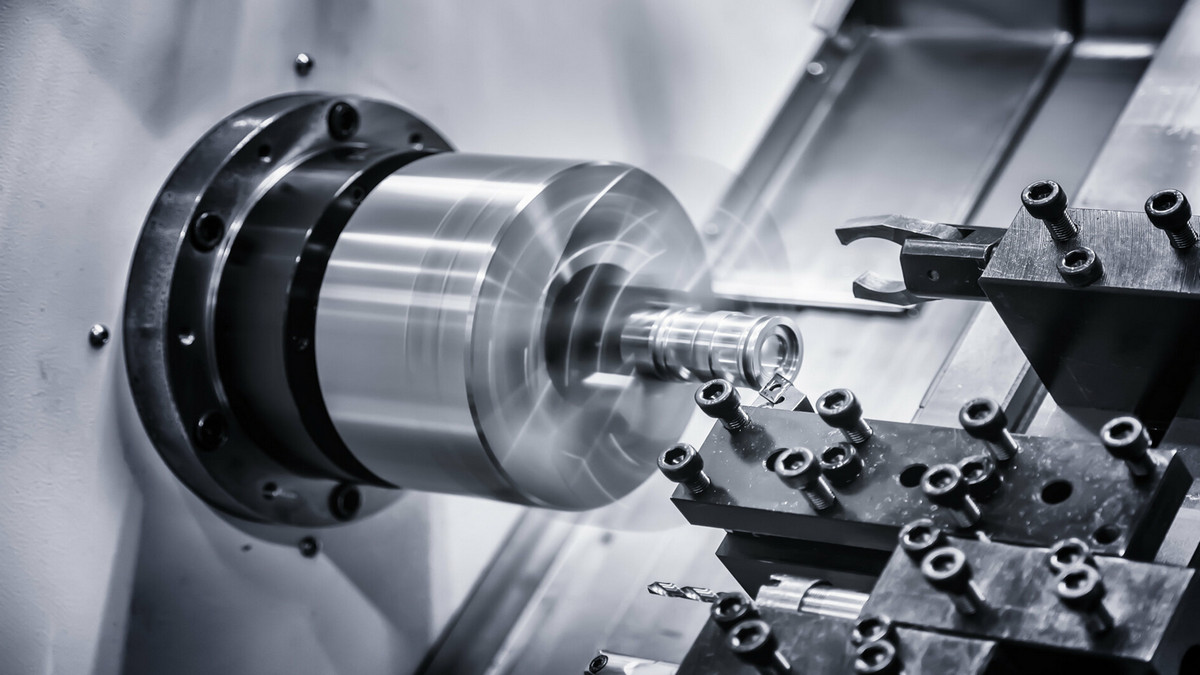

As the global manufacturing sector regains momentum following recent supply chain disruptions and economic slowdowns, multinational companies are re-evaluating where and how they source their machinery. Taiwan—once viewed as a mid-tier supplier—is now emerging as a strategic investment destination for global brands seeking high-precision CNC machining, tooling innovation, and smart manufacturing integration. With projections of double-digit growth for 2025 following a temporary downturn, Taiwan’s machine tool sector is proving its resilience and global competitiveness. As demand for automation, customization, and advanced manufacturing solutions intensifies, more international buyers are shifting their attention - and capital - toward Taiwan’s CNC and precision tooling ecosystem.

2025-05-07 10:24:20

Established in 1988 and headquartered in the heart of Taiwan’s manufacturing hub, Taichung City, Chung Sing Machinery Co., Ltd., operating under the well-known brand name FORTWORTH, has earned a global reputation for excellence in the design and manufacturing of high-performance boring and milling machines. With over 30 years of engineering expertise, Chung Sing is a trusted partner for companies seeking advanced, reliable, and cost-effective machining solutions.

2025-04-23 11:15:28

Established in 1988, Earth-Chain Enterprise Co., Ltd. is a leading Taiwanese manufacturer of magnetic workholding solutions. With over three decades of experience, more than 30 patents, ISO 9001 and CE certifications, and multiple prestigious awards—such as the Taiwan Excellence Award and the Taiwan SMEs Innovation Award—Earth-Chain has earned a global reputation for excellence in the design and manufacturing of Electro-Energetic Permanent Magnets, more commonly known as Electro-Permanent Magnetics (EEPM), including Electro-Permanent Magnetic Chucks, Permanent Magnetic Clamping Blocks, Electro-Permanent Lifting Magnets, and more. As a pioneer in magnetic clamping systems, Earth-Chain's private label "E.C.E." is distributed across five continents through a network of agents and distributors in more than 40 countries. The company’s dedication to innovation, honesty, and responsibility makes it the ideal partner for high-performance magnetic solutions.

2025-04-23 10:53:07

Let's explore the definitions of planers and shapers. Planers and shapers are both machine tool applications frequently found in the machine tool industry.

2024-12-25 09:39:08

Fiber laser welding is an advanced welding technology that uses a highly focused laser beam generated through fiber optics, enabling accurate and high-speed material joining with minimal thermal distortion. Fiber laser welding technology has revolutionized manufacturing industries with its precision, efficiency, and versatility, offering innovative, efficient, and environmentally friendly solutions.

2024-12-24 14:03:22

Rotary Indexing Plates are precision components of milling machines that facilitate the precise angular positioning of workpieces and cutting tools. They are used in both metal machining and woodworking, and while they share a fundamental purpose, there are notable differences in their design, capabilities, and applications due to the distinct characteristics of the materials and processes involved.

2024-11-18 15:19:30

Metal and wood planing machines are essential tools in the machining industry. Wood planers use a rotating cutterhead equipped with sharp blades to smooth and size workpieces, ensuring uniformity in woodworking projects. Metal planers use a cutting tool mounted on a reciprocating tool head to remove excess material from metal surfaces, achieving precise dimensions in components. Both types of planning machines enhance efficiency, precision, and the overall quality of finished products. Understanding the key features of the various types of planing machines will help you choose the right machine best suited for your machining needs.

2024-11-18 14:45:43

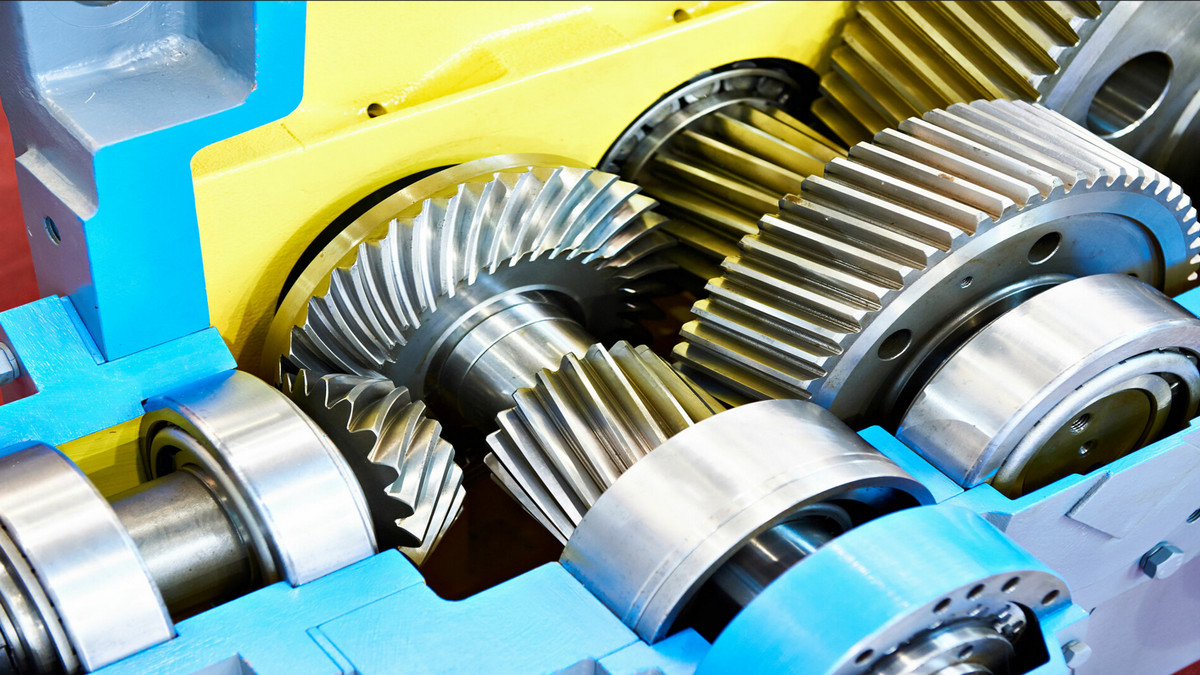

Speed reducers are powerful mechanical devices generally used in machining tools to multiply the force or torque generated by an input power source, thereby increasing the usable force, enhancing the performance and precision of the machining tool. They are also used in material handling systems such as conveyor belts and lifting mechanisms to control the speed of material transfer and manage heavy loads efficiently. By multiplying the available output force, they enable the use of a reduced input power source, resulting in cost savings for machine tool investments. When choosing the appropriate speed reducer, the torque, speed, and horsepower of the input, as well as the mounting configuration, efficiency, and required lifetime all need to be considered. The quality of the machine chosen will also be reflected in the amount of backlash, transmission error, torsional rigidity, and inertia experienced during machining.

2024-10-28 14:07:11

Stamp press technology, also known as stamping or pressing, is a manufacturing process that utilizes a press to shape or cut materials into desired forms. This process involves the use of a die and a punch to form or cut the material, creating intricate shapes with high precision. Widely employed for mass production due to its speed, accuracy, and repeatability, this process is a crucial part of modern manufacturing.

2024-10-28 13:45:08

The traditional image of saws as just cutting tools is being reshaped by cutting-edge advancements that integrate automation and robotics in sawing technologies, paving the way for greater precision and efficiency of sawing technology in manufacturing.

2024-10-28 11:14:18

The integration of additive manufacturing (AM) and subtractive milling processes has emerged as a transformative manufacturing process known as hybrid milling. This technique combines the strengths of both 3D printing and traditional subtractive milling, opening up new possibilities and diverse applications for creating complex geometries with improved material efficiency.

2024-10-28 09:37:52

Industrial saws shape raw materials into precise components that form the backbone of countless products. Understanding the mechanics of sawing, examining the fundamental principles, cutting mechanisms, and essential aspects of safety and maintenance will ensure the most efficient and safe operation of industrial saws.

2024-10-25 13:46:47

Industrial saws play a pivotal role in processing a wide range of materials with precision and efficiency. Taiwan is a major supplier of industrial saws to the automotive, aerospace, and construction, as well as the metal fabrication industries. This article aims to provide a comprehensive understanding of the diverse industry of industrial saws, exploring their types, structures, applications, and the crucial role they play in various industries.

2024-10-25 13:41:07

In machining manufacturing, drilling machine technology plays a pivotal role in shaping the efficiency and precision of the industry. The integration of artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) along with Industry 4.0 in drilling operations has been driving enhanced precision and overall productivity.

2024-10-25 10:45:47

Technological advancements in the machine tools industry are constantly shaping the way manufacturers approach production. The integration of Smart Milling Machines with the Internet of Things (IoT), often referred to as Industry 4.0, propels the industry toward unprecedented levels of efficiency and productivity.

2024-10-24 14:50:30

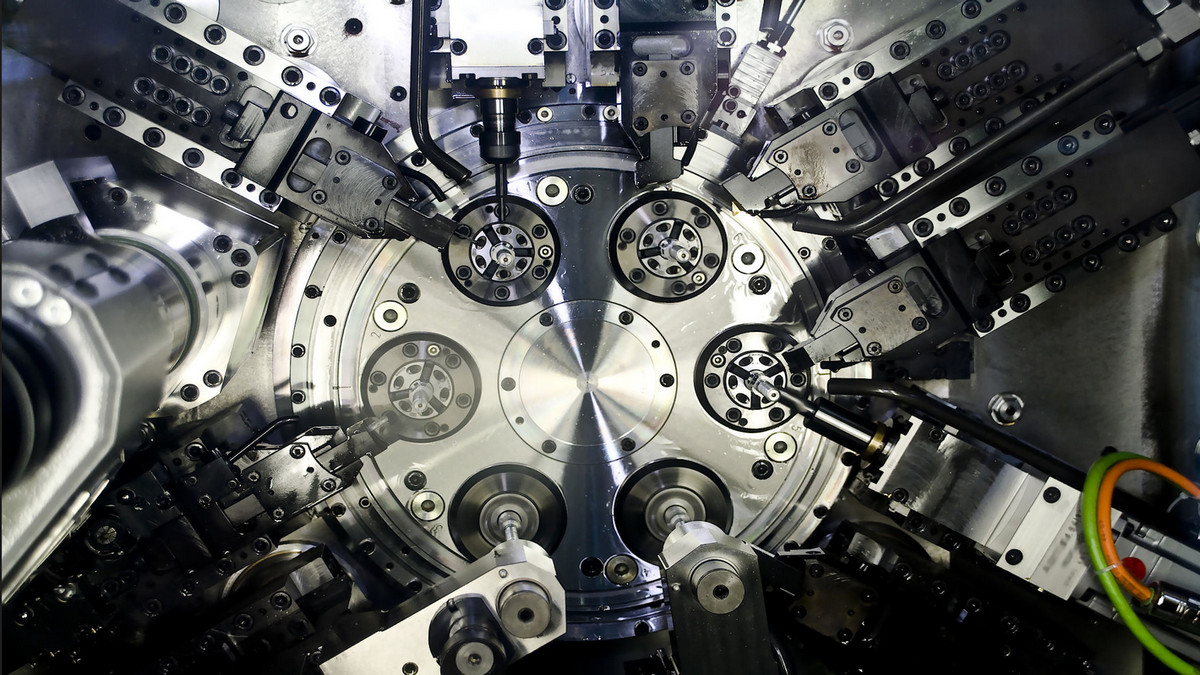

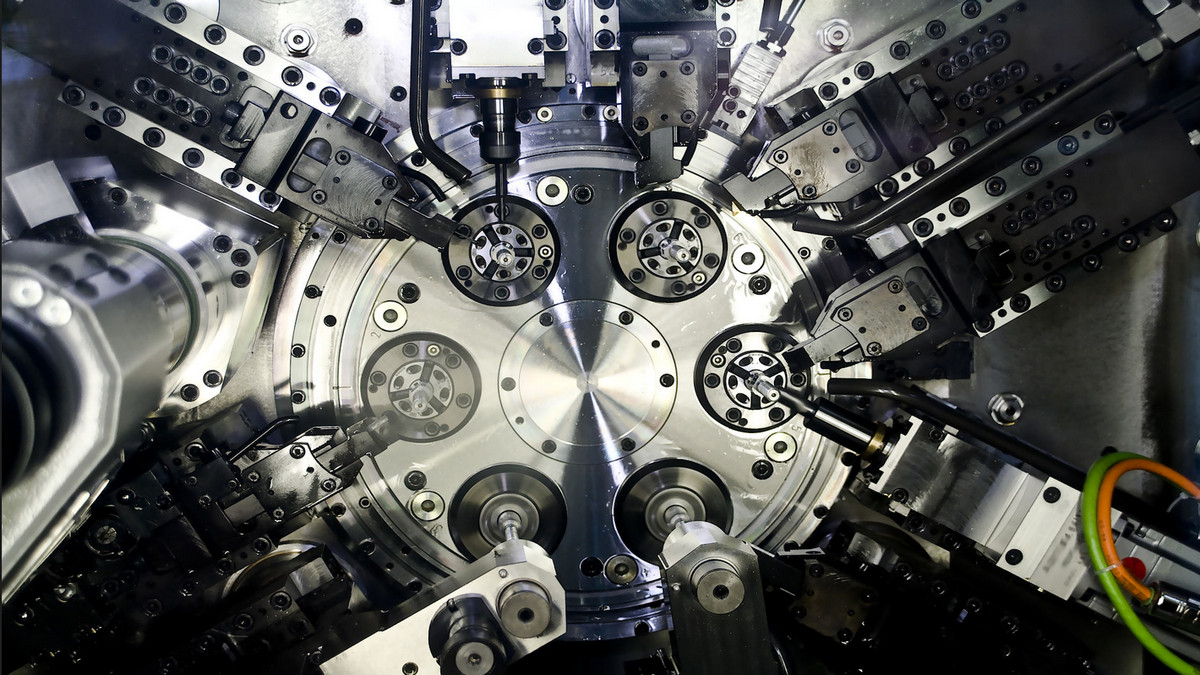

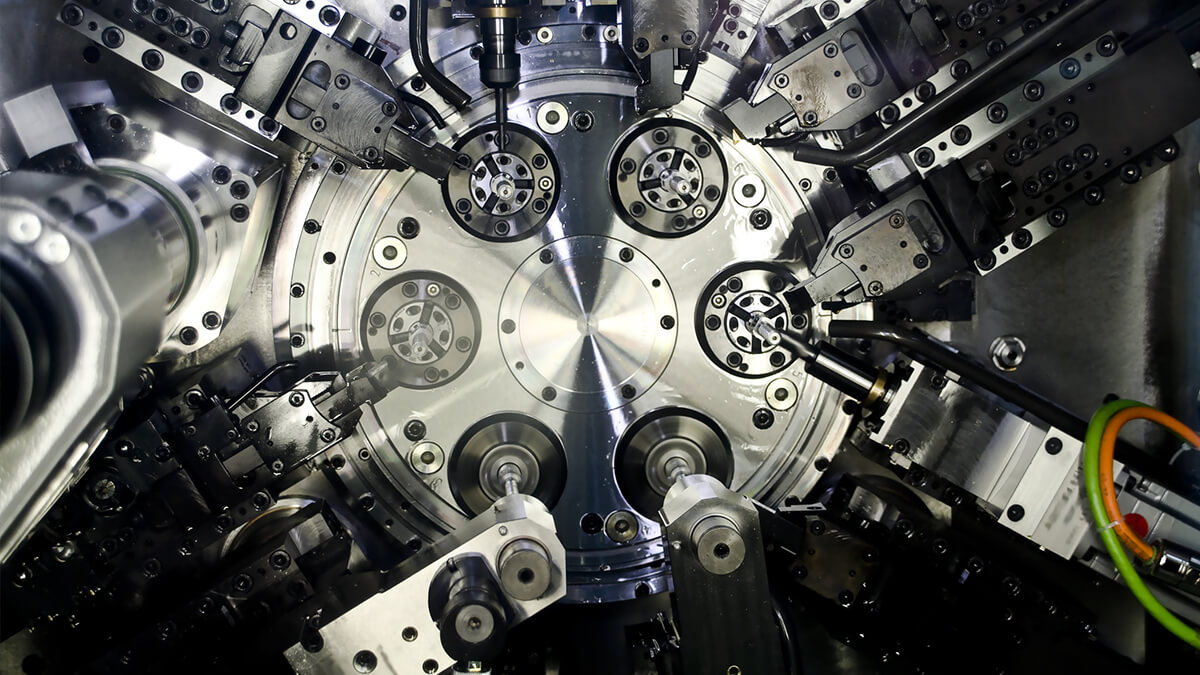

Advancements in Computer Numerical Control (CNC) milling technology have propelled CNC milling machines into a new era of precision, speed, and efficiency. Nano-machining allows the fabrication of components and structures with dimensions on the nanometer scale, typically ranging from 1 to 100 nanometers. These technological advancements, combined with the integration of artificial intelligence (AI) and automation, have had a profound impact across manufacturing industries.

2024-10-24 14:10:25

Milling machines are versatile tools that play a pivotal role in shaping and carving materials with precision and accuracy. The milling process involves the removal of material from a workpiece using a rotating cutter. As the cutter moves across the workpiece, it shapes and refines the material, creating intricate designs or precise components. The milling process can mill a workpiece's single face, called face milling, or perform peripheral milling and complex machining operations.

2024-10-24 14:05:32

The integration of robotics into grinding processes can greatly transform traditional manufacturing into dynamic environments where human workers and robots collaborate seamlessly. While robotics offers precision, consistency, and efficiency, skilled operators are essential for the efficient operation of advanced grinding machines. Training programs are important to provide hands-on education, certification, and expertise in setup, operation, and troubleshooting for optimal performance.

2024-10-23 13:58:59

From the rudimentary stones used in ancient times to the highly sophisticated wheels of today, the evolution of grinding wheel materials and design has been marked by a relentless pursuit of precision and efficiency. Early grinding wheels were often made from natural abrasives like sandstone. Today, materials such as aluminum oxide and silicon carbide, along with advancements in design and the introduction of additive manufacturing, have revolutionized the grinding process.

2024-10-23 13:40:59

The integration of cutting-edge technologies in the machine tools industry is reshaping the way manufacturers approach grinding processes. One transformative force is the Internet of Things (IoT), which enhances performance and enables predictive maintenance in smart grinding systems. Real-world applications are showcasing the power of these innovations.

2024-10-23 12:04:38

Agree