The traditional image of saws as just cutting tools is being reshaped by cutting-edge advancements that integrate automation and robotics in sawing technologies, paving the way for greater precision and efficiency of sawing technology in manufacturing.

Latest Cutting-Edge Technologies

The phrase "cutting-edge" takes on a literal meaning as technological advancements in robotics, automation, laser guidance systems, nanotechnology, materials, and design, transform the functionality and efficiency of industrial saws.

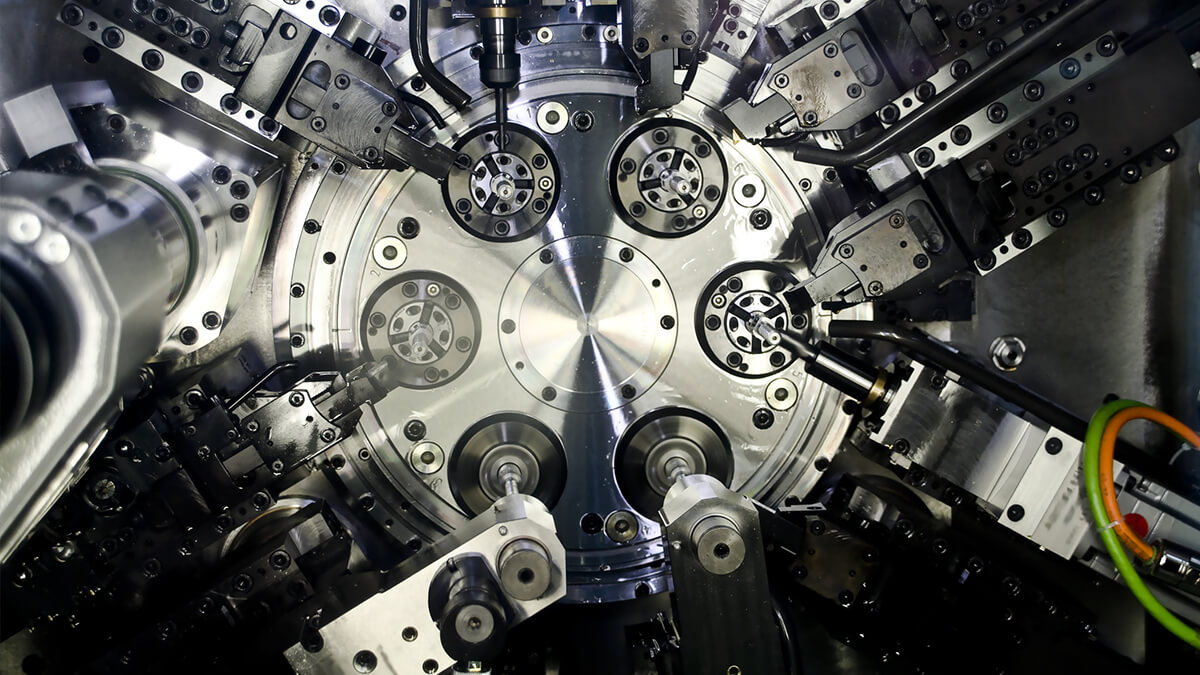

Robotics and Automation

The rise of robotics in manufacturing is reshaping sawing technology. Automated systems with robotic arms equipped with advanced sensors and AI algorithms scan materials and perform intricate cuts with unparalleled precision.

Researchers from MIT have created a new system of robot-assisted cutting called AutoSaw. It is comprised of design software that controls semi-autonomous robots. Users select a template from the software (like a chair, table, or shed) and then tweak the size and shape to their liking. This template is then converted into instructions for the robots, which autonomously pick up and saw the necessary materials to the correct size

In larger manufacturing facilities, automated panel saws are specifically designed for cutting large wooden panels with high accuracy and efficiency. These machines utilize advanced sensors and software algorithms to accurately cut panels into various shapes and sizes according to programmed specifications, ensuring consistency in production.

Laser Guidance Systems

Laser guidance systems have been integrated into various types of saws. These systems are mounted onto the saws and project a laser guide onto the material, ensuring that tools are properly positioned, and operators can make precise cuts along the designated path. Additionally, these systems can be used in conjunction with machine-vision cameras to serve as a reference point for machine inspection and robot guidance. The result is enhanced accuracy and reduced material waste.

Nanotechnology in Blade Design

The well-known power tool company Bosch Power Tools has recently developed a unique micro-cutting solution that incorporates a mini saw bar with a revolving micro-chain, similar to a chainsaw but much smaller. This innovative technology eliminates the up-and-down movement typical of jigsaws and saber saws, along with the strong vibrations that can push the saw off course.

Its unique design eliminates the need for constant blade adjustments, reducing downtime and increasing overall productivity. The NanoBlade's durability ensures a longer lifespan, making it a cost-effective choice for those in the machine tools industry. The long-lasting NanoBlades require no maintenance—no oiling, sharpening, or retensioning of the chain is needed—and the lack of vibration makes sawing less tiring.

Sustainability, Blade Materials, and Energy Efficiency

In the quest for sustainability, manufacturers are exploring alternatives to traditional blade materials, incorporating recycled and eco-friendly materials without compromising cutting performance. Sawing processes are being optimized to minimize energy consumption by integrating smart controls and variable-speed drives, ensuring efficient energy use without compromising performance.

Taiwan’s Cutting Edge

Taiwan is a key player in the export of sawing machinery. Taiwan's sawing technology industry has many well-developed manufacturers, suppliers, and research institutions. The United States, Germany, and Japan are among the major consumers of these products, recognizing the superior quality and technological innovation synonymous with Taiwanese manufacturing.

.jpg)

.png)