Radio Frequency Identification (RFID) is a technology used to identify items in a unique manner by the use of radio waves. It is unique in that it is capable of scanning hundreds of objects at the same time. Although the term of RFID is not often heard, we use it in our daily lives more than we realize, and its use continues to increase.

Although the term of RFID (Radio Frequency Identification) is not often heard, it is actually very widely used in daily life. RFID is mainly used for identity recognition. Its instantaneous message transmission saves a lot of manpower and time when scanning and inventorying products. RFID is also one of the foundation technologies in Near Field Communication (NFC). This post introduces the principles and applications of RFID, as well as how they differ from traditional barcodes and NFC.

RFID (Radio Frequency Identification)

RFID (Radio Frequency Identification) is a technology that uses radio waves to passively identify a tagged object. It is used in commercial and industrial applications for tracking items along a supply chain, as well as in storage facilities to keep track of items such in a library’s checkout system. It was originally used to identifying airplanes as “friend or foe” during World War II, to avoid accidental injury to one's own side. Later, businesses such as Wal-Mart and American retailer took the lead in introducing an RFID system to manage the inventorying of goods. This move made RFID a new favorite among retailers and in major shopping malls.

The advantages of RFID include long-distance reading and writing, one-to-many reading, reusability, high stain resistance, and high penetration. Compared with traditional barcodes, the reading range of RFID is much wider. Items do not need to be individually scanned, and can be scanned even when inside packaging. They are resistant to harsh environments and are not easy to damage.

Information on a standard barcode cannot be changed after printing, but the RFID electronic label can be updated at any time. The application range of RFIDs is wider than that of barcodes, and because the processing speed is very fast, they are widely used in retail industries.

What is the Principle of RFID?

RFID is a "wireless communication technology", so its signals are transmitted without contact. A complete RFID system consists of three parts; electronic tags, readers (card readers), and application databases (back-end computers). Through wireless communication technology, the electronic tag transmits the data to the reader. The reader then transmits the data to the database, where it is processed and stored. Electronic tags and readers "identify" the electronic ID tag, and let the computer manage the corresponding information.

RFID Daily Life Applications

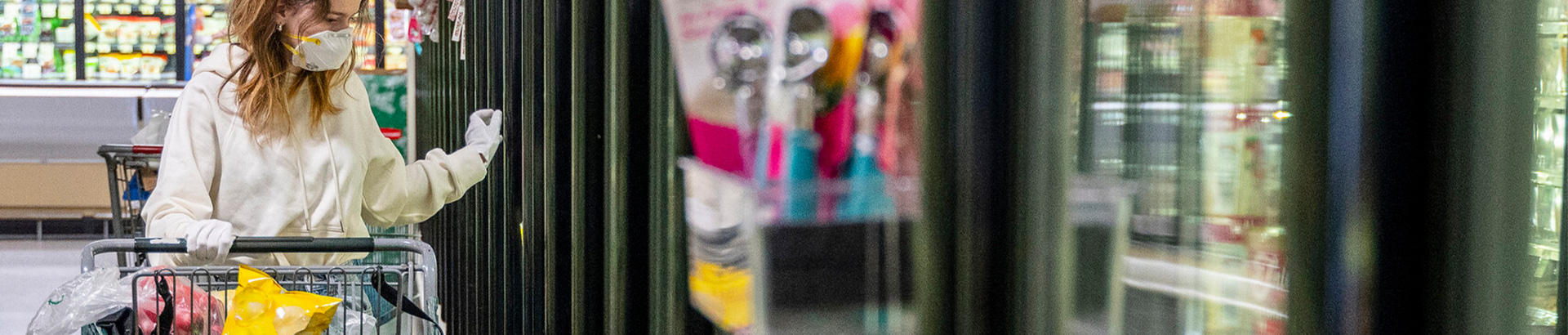

RFID is also commonly used in access control systems, car alarms, document management, production line automation, parking lot control, inventory management, personnel tracking, ID badging, supply chain management, counterfeit prevention (e.g., in the pharmaceutical industry), and more.

Because RFID does not require actual contact, it can also perform high-speed mobile reading. RFID electronic tags are often used in logistics management. It can be attached to items on the production line to grasp the location of items, track production time, location, color, arrival point, etc.

In a library system, besides the one-to-many sensing used to sense and record books borrowed and returned, RFID can simplify the keeping of book inventory. And because RFIDs are stain resistance, transmission will not be affected by printing with ink, so RFIDs can have labels printed on them. Anti-theft and access control systems are also some of the more important applications of RFID.

Near Field Communication (NFC) is based on RFID technology, but unlike RFID, NFC can exchange information. NFC, also referred to as short-range communication, integrates the electronic label and the card reader into one. It uses a set of communication protocols to enable two electronic devices to communicate within a short distance and exchange data without pairing. An example of an NFC is a card which passengers can use for public transportation that keeps track of the transportation payments. With the rise of smart phones and electronic wallets, many RFID applications are gradually switching to NFC.

RFID still has shortcomings in privacy and security that need to be overcome

RFID makes life more convenient, but there are also concerns about privacy and data security. If RFID has no other security protection measures, anyone with a reader can read it. For example, even after a shopper has left a shopping mall, through long-distance reading, information from an RFID tag can be gathered to evaluate the persons shopping habits. The same situation can also be applied to parking lot RFID tags. If the parking permit uses RFID, the owner's whereabouts can be tracked by RFID reading.

Due to their high cost, RFID is not as widespread as traditional barcodes, but in this modern age, where technology is changing daily, they are more and more becoming a part of our daily lives. Although RFID brings many conveniences to our lives, there is a need for more developments in the collection and management of transportation and consumption information, and development possibilities are worth looking into.

.jpg)

.png)