In-mold manufacturing, casting and forging are often used for processing. What is the difference between these two manufacturing processes?

What is Casting?

Casting is a process of smelting metal into a liquid that meets certain requirements, and then pouring it into a mold. After cooling, solidification, and cleaning, a casting (part or blank) with a predetermined shape, size, and performance is obtained. It is one of the basic processes of the modern machinery manufacturing industry.

Casting can be divided into gravity casting and low-pressure casting:

- Gravity casting: The manufacturing process is simple, and the liquid alloy is poured into the mold to cool and form. Since the casting mold is durable and the construction method is simple, it is a low-cost manufacturing method.

- Low-pressure casting: The liquid alloy is pressed into the mold at low pressure so that the molecular distribution is even. Because the pores are less and the metal density is higher, the casting is stronger. Low-pressure casting can be safer than with gravity casting but the process can be more complicated.

Casting process:

- Mold (container) : The liquid alloy is pressed into the mold at low pressure so that the molecular distribution is even. Because the pores are less and the metal density is higher, the casting is stronger. Low-pressure casting can be safer than with gravity casting but the process can be more complicated.

- Melting and pouring of cast metals: Cast metals (cast alloys) mainly include cast iron, cast steel, and cast non-ferrous alloys.

- Casting treatment and inspection: Casting treatment includes removal of foreign matter on the core and casting surface, removal of pouring risers, relief grinding of burrs and seams and other protrusions, as well as heat treatment, shaping, anti-rust treatment, and rough machining.

Mechanical properties of material structure:

After the metal is heated and poured into the mold, it recrystallizes. As the metal recrystallizes it forms fine grains with uniform size, so is harder but more brittle than forged items. The cast item can be treated to improve metal plasticity and mechanical properties, but the strength and elasticity will be relatively lower than that of forgings of the same material.

The advantages of casting are:

The cost is lower, and there are no restrictions on the shape. It will be strong but brittle. The cost of the mold used for casting is low, so it more economical to use for parts with complex shapes, especially with complex inner cavities. It has wide adaptability and good comprehensive mechanical properties. High plasticity when melted means less processing. Parts with complex shapes can reduce the cost of processing and internal and external angles are relatively straight.

The disadvantages of casting are:

There are many materials (such as metal, wood, fuel, molding materials, etc.) and equipment (such as metallurgical furnaces, sand mixers, molding machines, core making machines, shakeout machines, shot blasting machines, cast iron plates, etc.) required for foundry production, and they can produce dust, harmful gas, and noise that pollute the environment.

Common casting applications:

Auto parts, motorcycle parts, bicycle parts, large casting parts, machinery industry parts, hand tool parts, transportation parts, mining parts, fitness equipment parts, aviation parts, hardware department parts, medical equipment parts, agricultural machinery parts, civil construction Industrial parts, air tool housings and cylinder turbines, blades, etc.

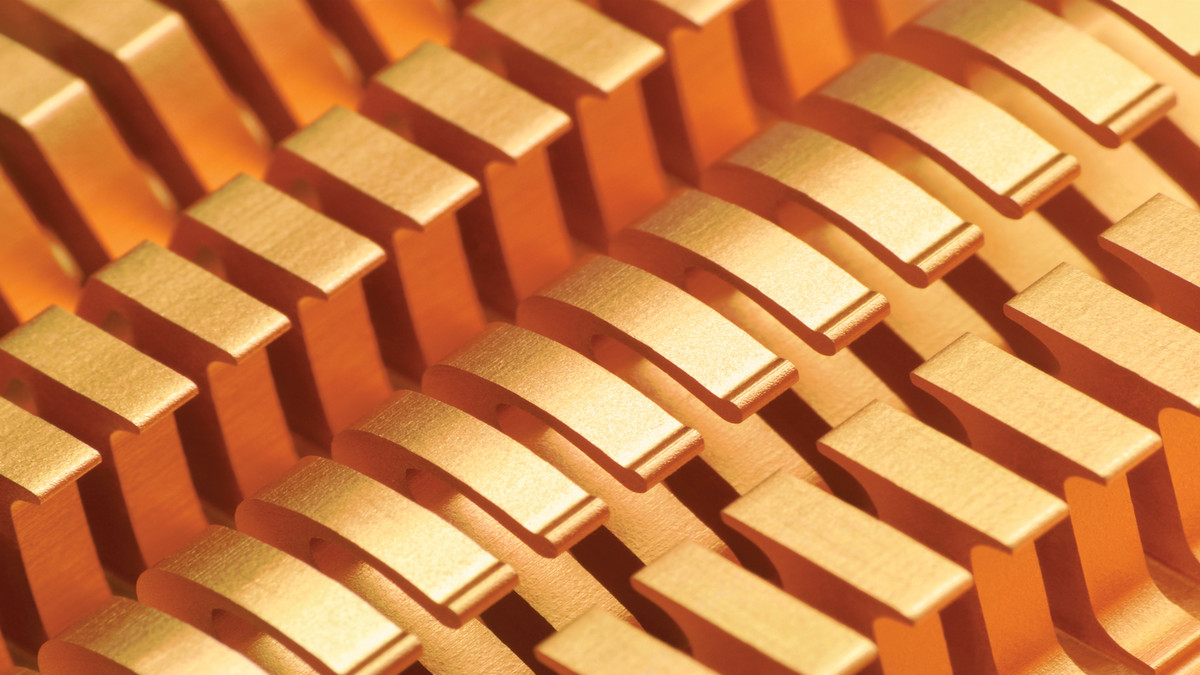

What is Forging?

Forging is a processing method that uses a forging machine to apply pressure to a metal blank to cause plastic deformation to obtain a forging with certain mechanical properties, certain shapes, and sizes.

Forging can be divided into open forging and closed mode forging according to the forming method:

- Open forging: Uses impact force or pressure to deform the metal between upper and lower irons (blocks) to obtain the required forgings. Forging can be done manually or mechanically.

- Closed mode forging: Forgings are obtained by pressing and deforming metal blanks in a forging die with a set shape. Forging processes can include die forging, cold heading, rotary forging, extrusion, etc. Forging can be divided into hot forging, warm forging, and cold forging according to the deformation temperature.

Mechanical properties of material structure:

Through the forging process, the metal can improve its structural and mechanical properties and ensure the continuity of the metal fiber structure, so that the fiber structure of the forging is consistent with the appearance of the forging. The metal forging flow line is complete, which can ensure high metal adhesion and good mechanical properties, improving the normal service life of the metal.

Through the forging process, the metal can improve its structural and mechanical properties and ensure the continuity of the metal fiber structure, so that the fiber structure of the forging is consistent with the appearance of the forging. The metal forging flow line is complete, which can ensure high metal adhesion and good mechanical properties, improving the normal service life of the metal.

The advantages of forging are:

Lightweight with high rigidity. Good physical properties, high wear resistance, high strength, superior tensile strength, impact resistance, fatigue resistance, long life, etc.

Materials used for forging are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, titanium, copper, etc., and their alloys. The original state of the material is a bar, ingot, metal powder, or liquid metal. The ratio of the cross-sectional area of the metal before deformation to the die cross-sectional area after deformation is called the forging ratio. Correct selection of forging ratio has a lot to do with improving product quality and reducing costs.

Common forging applications:Auto parts, motorcycle parts, bicycle parts, electric vehicle parts, machinery industry parts, chemical industry parts, fitness equipment parts, civil construction industry parts, medical equipment parts, machine tool parts, aviation parts, transmission parts, furniture and home accessories parts, mining parts, transportation parts, hand tool parts, agricultural machinery parts, air tool parts, etc.

.jpg)

.png)