As the world trend changes and the Occupational Safety and Health Law is promulgated around the world. In recently, Industry safety plays important roles, here we focus on stamping and shearing machinery technology to tell you the way to protect yourse

Risk factors for stamping operations

According to the analysis of the cause of the accident, the dangers in stamping operations mainly include the following aspects:

-

Dangers of equipment structure

Some stamping equipment uses rigid clutches. This is the use of a cam or coupling key mechanism to engage or disengage the clutch. Once engaged, it must complete a cycle before it stops. If the hand cannot be pulled out of the mold in time during the downstroke in this cycle, a hand injury will inevitably occur.

-

Device movement out of control

The equipment will also be subjected to frequent strong shocks and vibrations during operation, causing some parts to be deformed, worn, and even broken, causing the equipment to run out of control and cause a dangerous continuous collision accident.

-

Switch failure

Malfunction of the switch control system of equipment due to human or external factors.

-

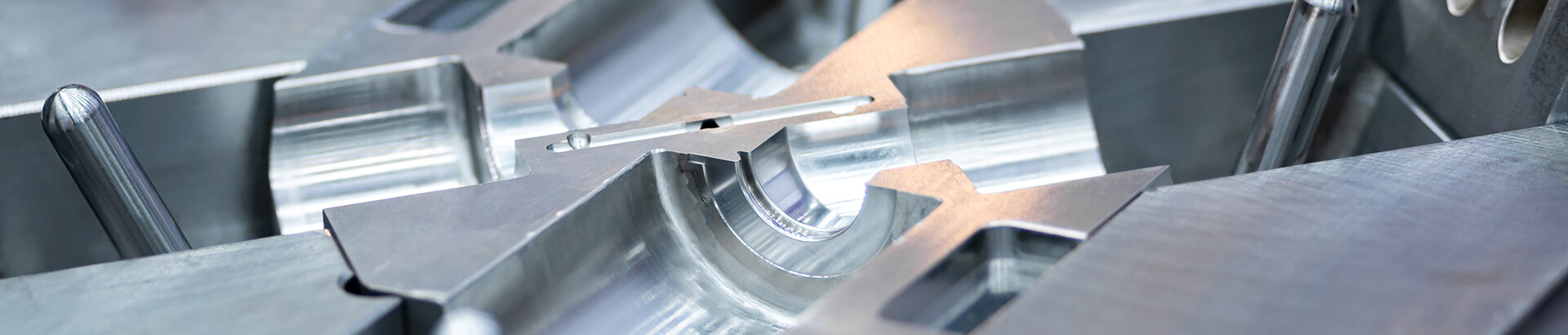

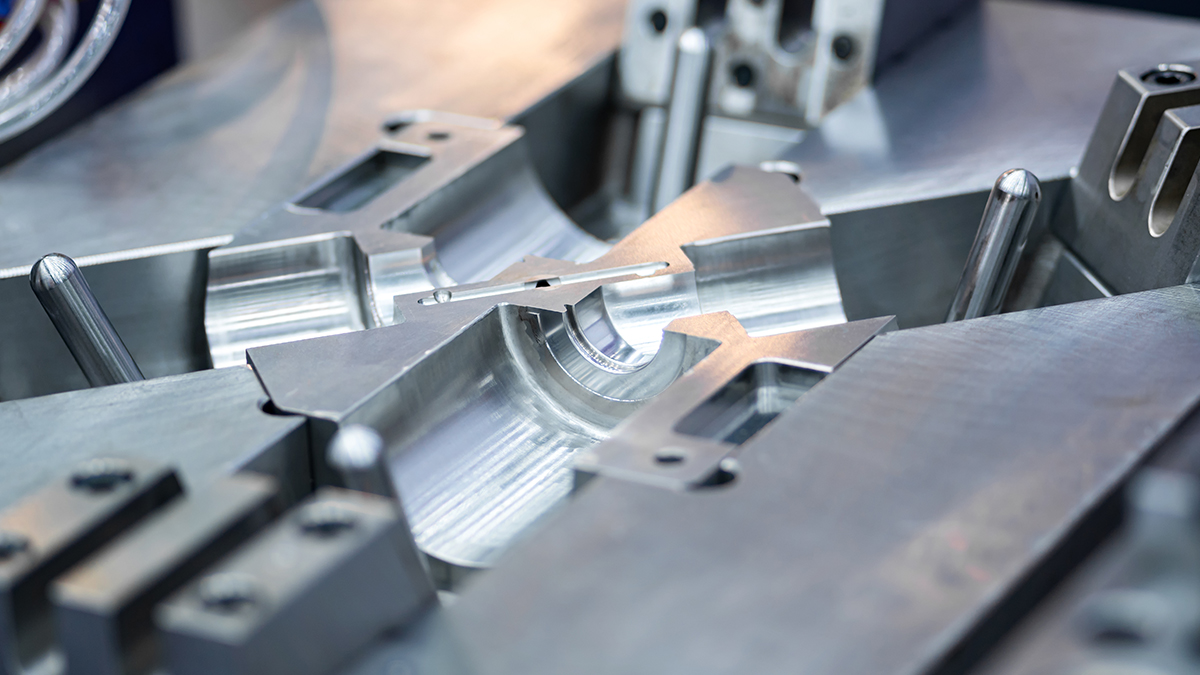

The danger of mold

The mold is responsible for the main function of machining the workpiece and is the centralized release part of the energy of the entire system. Unreasonable or defective mold design can increase the possibility of injury. Defective molds may cause accidents under normal operating conditions due to wear, deformation, or damage.

Safety technical measures for stamping operations

-

Use security tools

When operating with safety tools, use a special tool to put a single blank into the mold and take out the punched parts and waste materials to achieve extra-mold operation, avoid directly reaching between the lower mold mouth with your hands, and ensure human safety.

Use manual tools with low labor intensity and flexible and convenient use. At present, the safety tools used are generally designed and manufactured according to the operating characteristics of the enterprise. According to its different characteristics, it can be roughly summarized into the following 5 categories: elastic clamps, special clamps (calipers), magnetic suction cups, vacuum suction cups, pneumatic chucks.

-

Protective measures for mold work area

The content of mold protection includes: setting protective plates (covers) around the mold; reducing the dangerous area and expanding the safety space by improving the mold; setting up mechanical feeding and discharging devices; instead of manual feeding and discharging, the operator's hands are separated from the die Outside the danger zone, implement operation protection. Mold safety guards should not increase labor intensity. The practice has proved that the use of composite molds, multi-station continuous molds instead of single-process molds, or the establishment of mechanical feeding and discharging mechanisms on the molds to achieve mechanization and automation can achieve improved product quality and production efficiency, reduce labor intensity, and facilitate operation 1. The purpose of ensuring safety is the development direction of stamping technology and the fundamental way to achieve stamping safety protection.

-

The safety device of stamping equipment

There are many forms of safety devices for stamping equipment, which is divided into mechanical type, button type, photoelectric type, and induction type according to the structure.

- Mechanical protective device

There are three main types:

- Push hand protection device:

It is a mechanical protection device that is linked with the slider and pushes the hand away from the die through the swing of the baffle

- Swing lever handguard is also called handguard:

It is a device that uses the principle of the lever to pull the hand away

- Handle safety device:

It is a device that uses pulleys, levers, and ropes to link the operator's hand movements with the slider movement.

The mechanical protective device has a simple structure and is easy to manufacture, but it has a great impact on operation interference. The operator does not like to use it and has limitations.

- The two-handed button protection device

It is a protection device controlled by an electrical switch. When starting the slider, it is mandatory to restrict the human hand outside the mold to achieve isolation protection. Only when the operator's hands press the two buttons at the same time, the intermediate relay is energized, the electromagnet acts, and the slider starts. The switch in the cam is in an open state before the bottom dead center. If any switch is released halfway, the electromagnet will lose power, and the slider will stop moving. The cam switch will not close until the slider reaches the bottom dead center, then release it Button, the slider can still return automatically.

- Photoelectric protection device

The photoelectric protection device is composed of a set of the photoelectric switch and mechanical devices. It is to set various light sources in front of the die to form a light beam and close the dangerous area on the operator's front side and above and below the die. When the operator stops or mistakes the area, the light beam is blocked and an electrical signal is sent out. After being amplified, the relay is activated by the control circuit, and finally, the slider automatically stops or cannot descend, thereby ensuring the safety of the operator. According to different light sources, photoelectric protection devices can be divided into infrared photoelectric protection devices and incandescent photoelectric protection devices.

Mechanization and automation of stamping operations

Because there are many stamping procedures, such as feeding, setting, discharging, cleaning waste, lubricating, and adjusting molds, the protection scope of stamping operations is also very wide. It is difficult to achieve protection on different procedures. Therefore, the mechanization and automation of stamping operations are very necessary.

The mechanization of stamping refers to the replacement of manual operations with the actions of various mechanical devices; automation refers to the automatic operation of the stamping process, which can be automatically adjusted and protected and can automatically stop when a fault occurs.

Safety Technical Measures of Shearing Machine

Shearing machine is a kind of shearing equipment that is widely used in the machining industry. It can cut steel plate materials of various thicknesses.

Commonly used shears are divided into three types: flat shears, rolling shears, and vibration shears, of which flat shears are the most used. Shearing machines with shear thickness less than 10mm are mostly mechanical transmission, and those with a thickness greater than 10mm are hydraulic transmission. Generally, a single or continuous cut of metal is performed with a foot pedal or button or operation.

Pay attention to when operating the shears

- Check carefully whether all parts are normal before work.

- One person should not operate the shears alone, and make sure that one person is in command.

- Adjust the clearance of the scissors according to the specified thickness of the shear plate.

- The belt, flywheel, gear, shaft, and other moving parts of the shears must be installed with protective covers.

- The distance of the shearing machine operator's feeding finger from the scissors' mouth should be kept at least 200mm, and away from the pressing device.

- The protective fence placed on the shears should not allow the operator to see the cut parts.

- The waste generated after the operation has edges and corners, the operator should remove it in time to prevent stab wounds and cuts.