What Are Cutting and Shaping Tools? From Traditional to Modern Uses

The term "cutting and shaping tools" might sound a bit unfamiliar, but it actually covers a wide range of tools used in fields from the kitchen and woodworking to industrial manufacturing. In simple terms, a cutting tool is any implement used to shave, scrape, cut, or plane away material. Its main purpose is to use a sharp blade to remove excess from an object's surface to achieve a desired shape, smoothness, or finish.

Published: Aug 07, 2025

Traditional Cutting Tools

The cutting tools we most commonly encounter in our daily lives typically fall into the traditional or household category.

- Kitchen Tools: These are the most common. Examples include peelers (used for peeling fruits and vegetables), graters (for shaving thin slices), and knives or chef's knives (for cutting ingredients). Their common feature is a sharp blade that can easily remove the surface layer of food.

- Woodworking Tools: In woodworking, cutting tools play a vital role. For instance, a wood plane can shave a wooden surface until it's smooth and flat, while a chisel is used to carve out joinery or detailed designs. These tools prioritize precision and durability.

- Art and Craft: In artistic creation like sculpting and printmaking, cutting tools are indispensable. Carving knives come in various shapes and sizes to precisely sculpt the details of a piece, while utility knives (or box cutters) are widely used for cutting paper, models, and more, thanks to their sharp, replaceable blades.

Modern and Industrial Cutting Tools: A Synonym for Precision and Efficiency

As technology has advanced, the application of cutting and shaping tools has become more widespread and automated, especially in industrial manufacturing. These modern tools not only offer higher precision but also far greater efficiency than traditional manual tools.

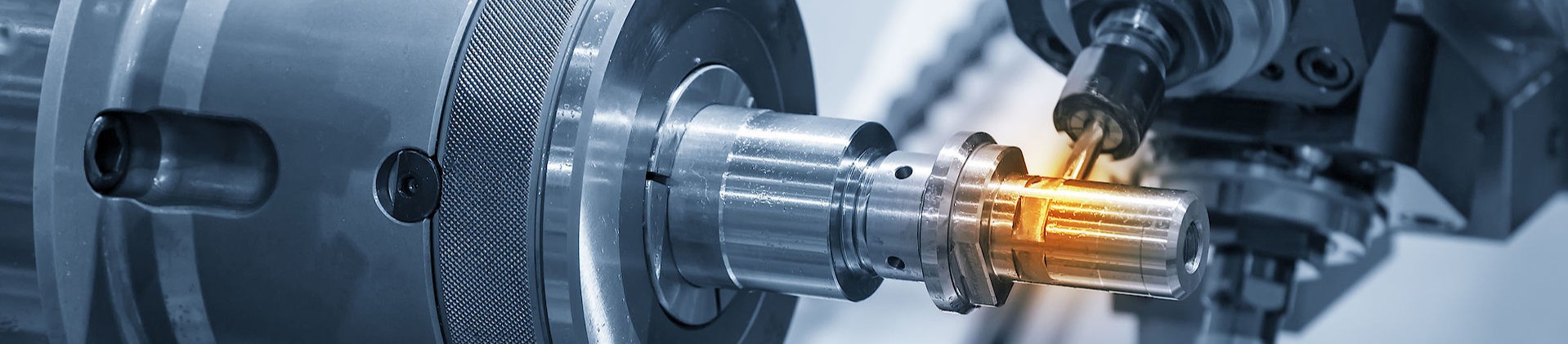

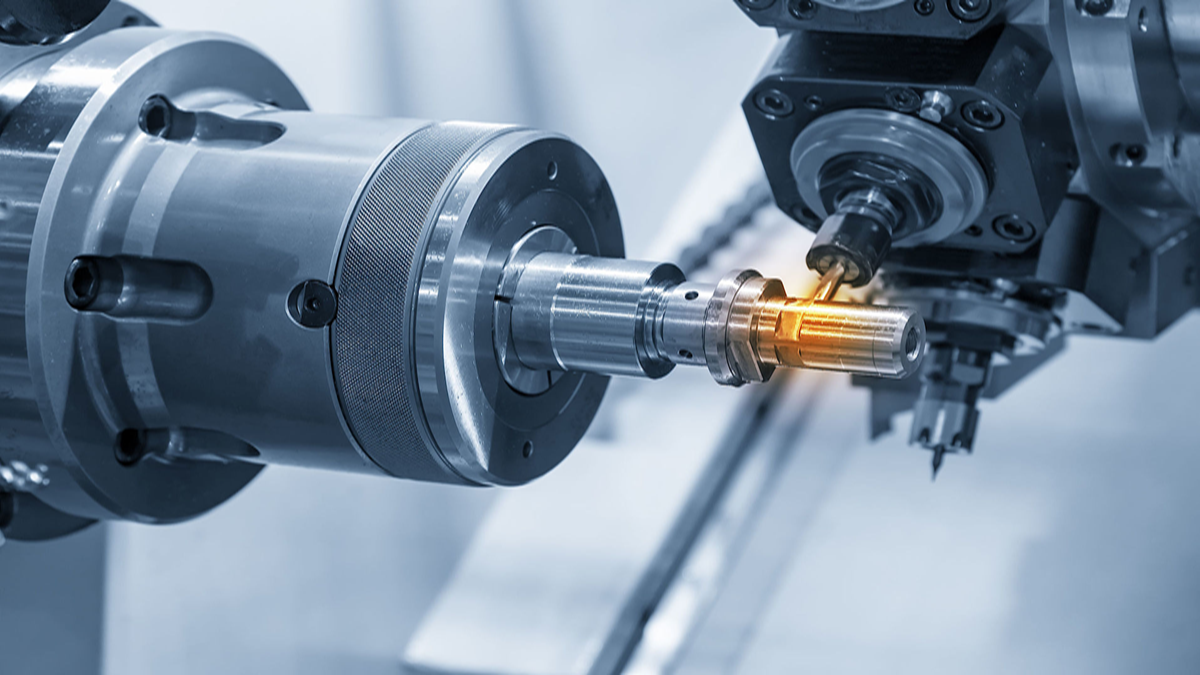

- Cutting Tools: In the manufacturing industry, these are referred to as "cutting tools." They are typically made from extremely hard materials like high-speed steel (HSS) and tungsten carbide. Some are even coated with a layer of diamond or titanium nitride to increase wear resistance and hardness. These tools are mounted on Computer Numerical Control (CNC) machines and can process industrial materials such as metal and plastic into the desired shapes with extreme precision and efficiency. Common examples of these cutting tools include:

- Lathe Tools: Primarily used in lathes to perform external, internal, and face cutting on cylindrical workpieces.

- Milling Cutters: Primarily used in milling machines to create flat surfaces, grooves, curved surfaces, and various other complex shapes.

- Drill Bits: Used for drilling holes, they are one of the most widely used tools in manufacturing.

- Electronics Manufacturing: In the production of semiconductors and other electronic products, specialized "cutting tools" are also used. For example, diamond saw blades are used to cut silicon wafers, with a precision requirement at the micron level that is far beyond the capability of traditional tools.

- Laser and Water Jet: Moving even further, modern industry uses non-traditional "blades." For instance, a laser cutting machine uses a high-energy laser beam to melt and vaporize material for contactless cutting. A water jet cutter uses a high-pressure stream of water mixed with an abrasive to precisely cut almost any material, from metal to stone. While these tools do not have a physical blade, their function and purpose are completely consistent with the core concept of a cutting tool.

Conclusion

From a potato peeler to an industrial milling cutter for precision parts, the essence of a cutting tool remains the same: to use a sharp "force" to change an object's shape and surface. They are not only helpful tools in our daily lives but also a cornerstone for the development of modern manufacturing. The next time you pick up a peeler, take a moment to think about the broader significance behind it.

Published by Aug 07, 2025

JUN-YI

gist

minaprem

.jpg)

.png)