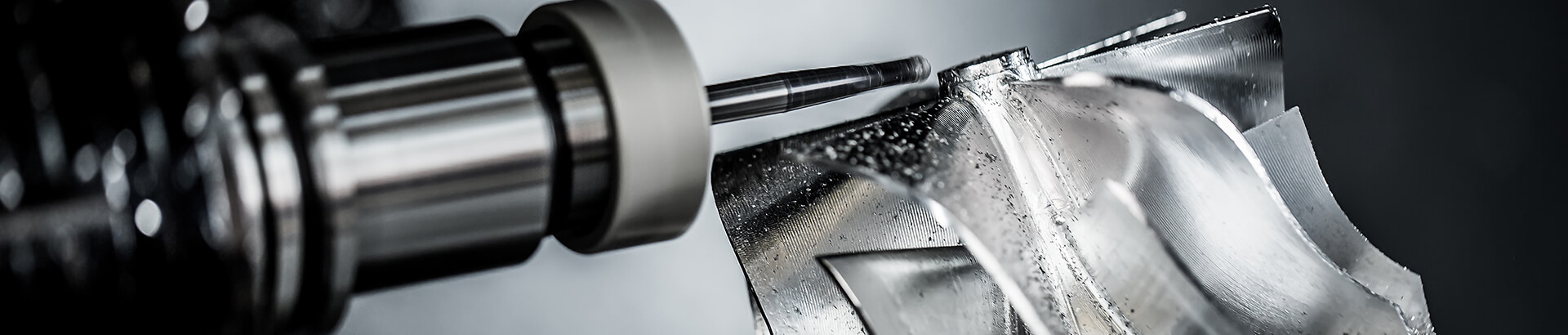

A lathe is a machine tool used principally for shaping articles of metal (and sometimes wood or other materials) by causing the workpiece to be held and rotated by the lathe while a tool bit is advanced into the work causing the cutting action.

What is a lathe?

The concept of lathe

The basic lathe that was designed to cut cylindrical metal stock has been developed further to produce screw threads, tapered work, drilled holes, and crankshafts. The typical lathe provides a variety of rotating speeds and a means to manually and automatically move the cutting tool into the workpiece. Machinists must be thoroughly familiar with the lathe and its operations to accomplish the repair and fabrication of needed parts.

A lathe machine is a machine tool that mainly uses a turning tool to turn a rotating workpiece. Drill, reamer, tap, die tools can also be used on the lathe for corresponding processing.

What are the parts of the lathe?

The parts of the lathe

The main components are: Headstock assembly, Toolpost, Tailstock, Lead screw, Feed rod, Bed, Leg and cooling device.

- Headstock assembly

Also known as the headstock, its main task is to pass the rotational motion from the main motor through a series of speed change mechanisms, so that the spindle can obtain the required forward and reverse rotation speeds, and at the same time, the spindle box separates parts. The power transmits the movement to the feed box. The main shaft in the headstock is the key part of the lathe. The stability of the spindle running on the bearing directly affects the processing quality of the workpiece. Once the rotation accuracy of the spindle decreases, the use-value of the machine tool will decrease.

- Lead screw and feed rod

used to connect the feed box and the slide box, and transmit the movement and power of the feed box to the slide box, so that the slide box can obtain longitudinal linear motion. The screw is specially set for turning various threads. When turning other surfaces of the workpiece, only the smooth screw is used instead of the screw. Students should distinguish the difference between the light screw and the lead screw based on the content of the slide box.

- Slide box

It is the control box for the feed movement of the lathe. It is equipped with a mechanism that converts the rotary motion of the light rod and the lead screw into the linear motion of the tool post. The longitudinal and lateral feed motion of the tool post is realized through the transmission of the light bar. And rapid movement, the tool holder is driven by the lead screw to make a longitudinal linear movement, so as to turn the thread.

- Tool holder

There are two layers of skateboards (medium and small skateboards), bed saddle and tool holder body. Used to install the turning tool and drive the turning tool to move longitudinally, horizontally or diagonally.

- Tailstock

Installed on the bed rail, and move longitudinally along this rail to adjust its working position. The tailstock is mainly used to install the rear center to support longer workpieces. Drills and reamers can also be installed for hole processing.

- Bed

It is a large basic part of the lathe with high precision guide rails (mountain guide rails and flat guide rails). It is used to support and connect the various parts of the lathe, and ensure that each part has an accurate relative position when working.

- Cooling device

The cooling device mainly uses a cooling water pump to pressurize the cutting fluid in the water tank and spray it to the cutting area to reduce the cutting temperature, wash away the chips, and lubricate the surface to improve the service life of the tool and the surface processing quality of the workpiece.

.jpg)

.png)