Micro Electrical Discharge Machining (Micro-EDM) has emerged as a transformative precision engineering technology, unlocking new possibilities for manufacturing intricate and miniature components. Micro-EDM offers unique capabilities in advanced applications, including medical device manufacturing, aerospace components, and miniaturized electronics. Several unique solutions have been developed to address exceptional challenges associated with micro-scale machining in the electronics industry, medical implant manufacturing, and aerospace turbine blade production.

Overview of Micro-EDM and Its Unique Capabilities

The Essence of Micro-EDM

Micro-EDM is an advanced machining process that extends the EDM into the micro-scale domain. What sets it apart is its ability to achieve sub-millimeter and even sub-micron level accuracies, making it an indispensable tool in the production of tiny, complex components.

Unique Capabilities:

High Precision: Micro-EDM can achieve extraordinary precision, making it ideal for creating intricate features and details with minimal tolerances.

Material Versatility: It is compatible with a wide range of materials, including metals, alloys, ceramics, and even exotic materials, expanding its application across diverse industries.

No Contact Machining: Micro-EDM is a non-contact machining process, minimizing the risk of tool wear and enabling the machining of fragile materials.

Minimal Thermal Impact: The process generates minimal heat, reducing the risk of thermal damage to the workpiece and preserving material properties.

Applications in Medical Device Manufacturing

One of the prominent applications of Micro-EDM lies in medical device manufacturing. The production of surgical instruments and other critical medical devices often involves Micro-EDM to meet the medical industry demands for components with intricate geometries and tight tolerances. From micro-scalpels to tiny forceps, the technology ensures the precision necessary for delicate medical procedures.

Micro-EDM contributes to the manufacturing of miniaturized implantable medical devices and components, such as pacemakers and neurostimulators. The ability to work with biocompatible materials further enhances its suitability for medical applications.

Crafting Micro-Components for Cardiovascular Stents

One noteworthy application of Micro-EDM in the medical field is the manufacturing of components for cardiovascular stents. These tiny mesh-like structures require precision engineering to ensure optimal performance. Micro-EDM's ability to create intricate patterns and structures with high precision makes it an ideal technology for producing these critical components.

Micro-EDM for Aerospace Components and Miniaturized Electronics

Aerospace Sensor Arrays

The aerospace industry demands extreme precision within electronic systems and sensors. Sensors play a crucial role in aerospace applications, providing data for navigation, monitoring, and control systems. Micro-EDM enables the creation of miniature sensor components with high precision, ensuring the accuracy of critical data in aerospace operations.

Micro-EDM has been instrumental in crafting sensor arrays for unmanned aerial vehicles (UAVs). These arrays consist of tiny, precisely machined components that are crucial for collecting and transmitting data. Micro-EDM has found a niche in the efficient and reliable production of these tiny components for aerospace systems.

Miniaturized Electronics: Shrinking Components, Expanding Possibilities

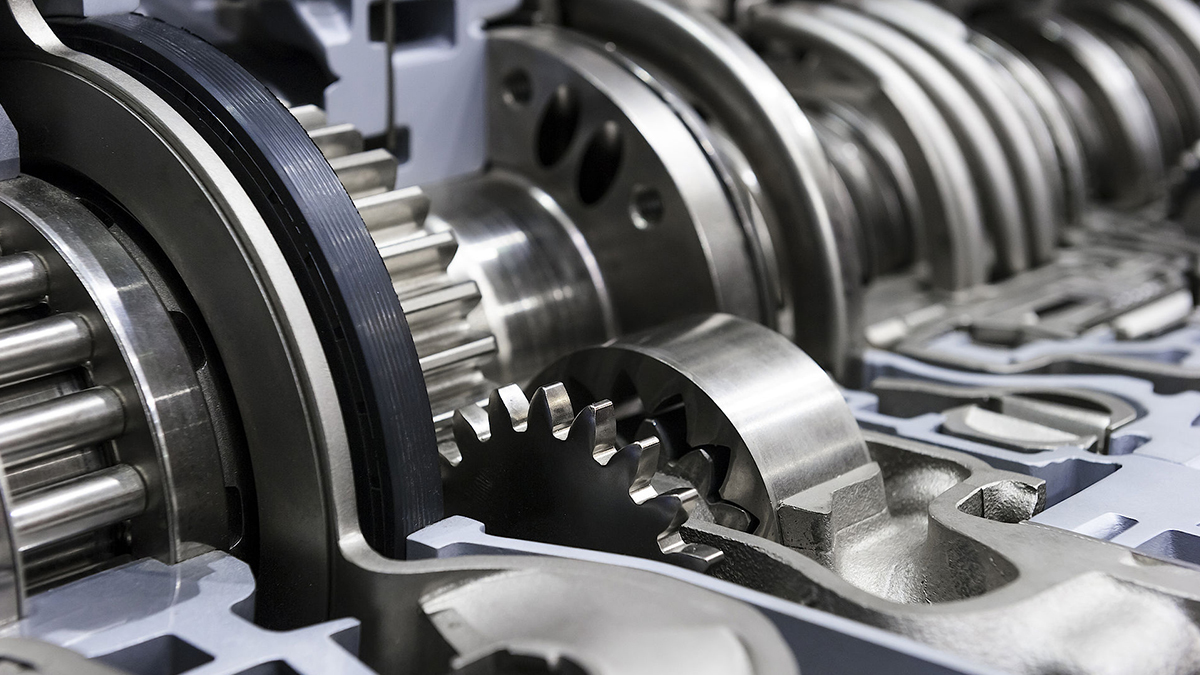

As electronic devices continue to shrink in size, the demand for micro-scale components has surged. Micro-EDM plays a vital role in manufacturing miniature electronic components, such as connectors, pins, and small gears, contributing to the miniaturization trend in electronics.

Challenges and Solutions in Micro-Scale Machining

Challenges in Micro-EDM include:

Electrode Wear: At the micro-scale, electrode wear becomes a significant challenge, affecting the overall accuracy and tool life.

Machining Fragile Materials: Working with brittle or delicate materials poses challenges, as excessive force or heat can lead to breakage.

Tool Path Control: Achieving precise tool paths at the micro-scale requires sophisticated control systems to prevent deviations and errors.

Solutions:

Advanced Electrode Materials: The development of advanced electrode materials, such as diamond-coated tools, has mitigated wear issues, ensuring prolonged tool life.

Adaptive Control Systems: Real-time adjustments in machining parameters based on sensor feedback enhance control, addressing challenges associated with machining fragile materials.

High-Resolution Imaging: Integrating high-resolution imaging systems enables better visualization and control of the machining process, ensuring accurate tool paths.

Showcase of Successful Micro-EDM Applications

Micro-Machining for the Electronics Industry

A company specializing in miniaturized electronic components utilized Micro-EDM to manufacture intricate connectors for handheld electronic devices. The technology's precision allowed for the creation of reliable connectors with sub-micron tolerances, meeting the stringent requirements of the electronics industry.

Medical Implant Manufacturing

Micro-EDM technology's ability to work with biocompatible materials and achieve sub-millimeter precision contributed to the successful production of miniature components crucial for the performance of implantable medical devices. In the fabrication of orthopedic implants, such as hip or knee replacements, Micro-EDM enhances not only the performance of the implants but also contributes to the overall success of surgical procedures.

Aerospace Turbine Blade Production

The aerospace industry relies on Micro-EDM for manufacturing turbine blades that demand intricate aerodynamic shapes while maintaining the structural integrity of these critical components. The technology's ability to work with exotic materials further enhances its significance in aerospace applications.

Micro-EDM stands at the forefront of precision engineering, opening doors to the creation of intricate and miniature components that were once deemed challenging or impossible to manufacture. From its unique capabilities to its diverse applications in medical device manufacturing, aerospace, and miniaturized electronics, Micro-EDM continues to redefine the boundaries of precision machining.

.jpg)

.png)