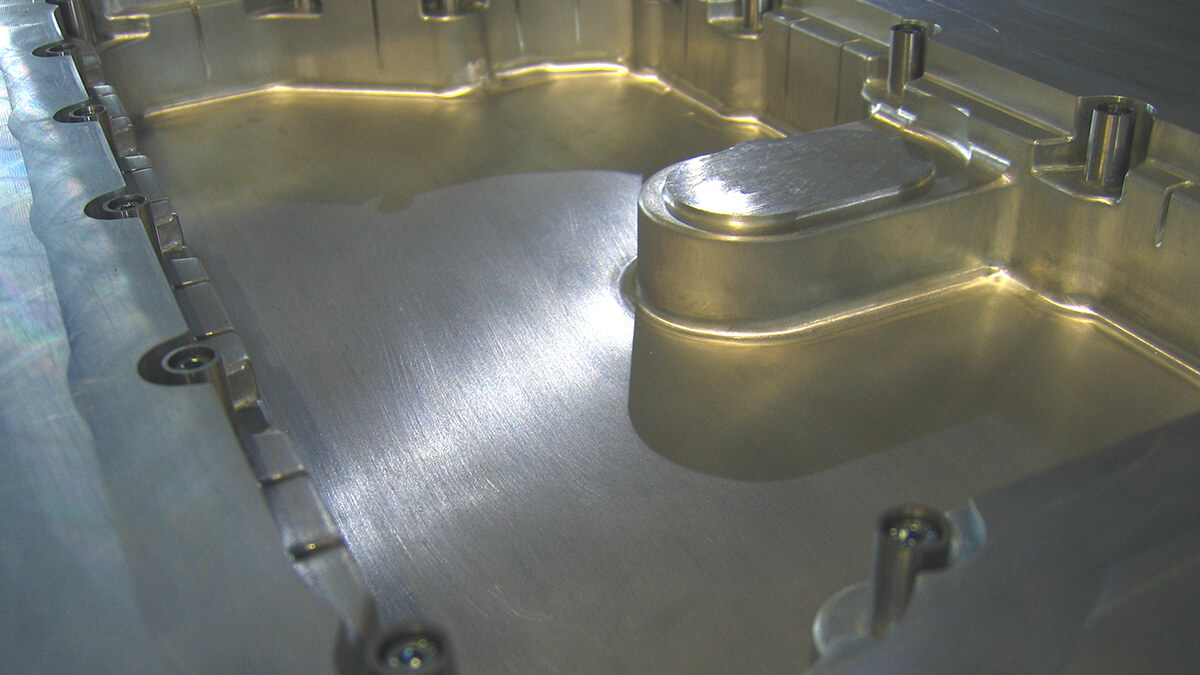

Die casting, or pressure casting, is a metal casting process characterized by the use of mold cavities to apply high pressure to the molten metal.

What Is Die Casting?

The mold is usually made of a stronger alloy, and the process is somewhat similar to injection molding. Most die-casting castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, a cold chamber dies casting machine or a hot chamber die casting machine is required.

The cost of casting equipment and molds is high, so the die-casting process is generally only used to mass-produce a large number of products. It is relatively easy to manufacture die-cast parts, which generally only requires four main steps, and the individual cost increment is very low. Die casting is particularly suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used in various casting processes. Compared with other casting technologies, the surface of die-casting is smoother and has higher dimensional consistency.

Based on the traditional die-casting process, several improved processes were born, including a non-porous die-casting process that reduces casting defects and eliminates pores. It is mainly used for processing zinc, which can reduce waste and increase the yield of the direct injection process. There is also a new type of die-casting process such as precision speed dense die-casting technology invented by General Dynamics and semi-solid die-casting.

The advantages of die casting include that the casting has excellent dimensional accuracy. Usually, this depends on the casting material, the typical value is the error of 0.1 mm at the initial 2.5 cm size, and the error increases by 0.002 mm for each additional 1 cm. Compared with other casting processes, the surface of its castings is smooth, and the radius of the fillet is about 1-2.5 microns. Relative to sandbox or permanent mold casting methods, castings with a wall thickness of approximately 0.75 mm can be produced. It can directly cast internal structures, such as wire sleeves, heating elements, and high-strength bearing surfaces. Some other advantages include its ability to reduce or avoid secondary machining, fast production speeds, the tensile strength of castings up to 415 MPa, and the ability to cast highly fluid metals.

The biggest disadvantage of die casting is its high cost. Casting equipment, molds, and mold-related components are relatively expensive compared to other casting methods. Therefore, it is more economical to produce a large number of products when manufacturing dies castings. Other disadvantages include: This process is only suitable for high-flow metals, and the casting quality must be between 30 grams and 10 kilograms. In normal die casting, the final batch of castings will always have pores. Therefore, any heat treatment or welding cannot be performed, because the gas in the gap will expand under the action of heat, resulting in internal micro defects and surface peeling.

An Effective Way To Reduce The Cost Of Die Casting Mold

Material selection is the basis, mold design is the key

The die-casting mold market is highly competitive, and most manufacturers pay special attention to the manufacturing cost of die-casting molds. According to the sharing of mold manufacturers, the basis for reducing the cost of die-casting molds is to choose good mold materials. Economical and reliable optimal design is the key to reducing mold costs. Reasonable management of processing procedures and reduction of design and processing errors are important means of reducing mold costs.

Choosing materials is the basis

When a die-casting manufacturer manufactures a mold, it must first be evaluated according to the customer's casting requirements and the number of die-casting market demands. If the number of die-casting castings is large, you can choose a better material to confirm the guaranteed life of the mold. If only the price is cheap, the die may not be die-cast, and it may be scrapped, which is not worth the loss.

Die casting machine is less than 350t, die template can choose S50C; die casting machine greater than 350t can choose FCD550, S50C; if greater than 2,000t, castings are car shell, variable shell, four-cylinder, three-cylinder, Sn2MC, S50C, P20, and other materials. On the other hand, if the customer has no special requirements, the mold side pumping cylinder can be used at a relatively cheap price, or the mold manufacturer can make accessories such as cylinder attachments and cylinder limiting devices, thereby saving mold costs. In addition, high-quality formwork and cylinders can be reused, and die casting can be continued by simply changing the mold cavity, saving mold costs.

Mold design is the key

The design of the mold should be calculated according to the size of the casting, and the tonnage of the die-casting machine should be reasonably determined by the projected area of the casting, and the mold structure (the number of cavities) should be confirmed. If the casting is bilaterally symmetrical or slender in shape, you can choose 1 mold and 2 cavities; if the casting is in large demand for a variety of small parts, the conditions of the die casting machine to allow you to choose 1 mold 2 cavities, 1 mold 4 cavities, 1 mold 6 cavities, etc. Multiple pieces can reduce costs. Mold design should determine the reference coordinate system according to the castings, rationally construct the parting surface according to the direction of the mold, and carry out the design of moving mold, fixed mold, and side core pulling. The first type of casting is placed parallel to the vertical and the side and has a compact design structure, saving material, simple processing, and a small total mold volume, which is beneficial to die casting. The second type of casting is not parallel to the end face of the sky side, and the mold cavity is obviously larger than the structure shown in the second piece, and the mold cost increases.

Conclusion

The design of the mold structure is based on the parting design, and the size of the mold cavity, the size of the template, the direction of the side-drawing slider, and the size of the cylinder are determined by pressing the tonnage of the casting machine. When designing the die-casting mold, it is necessary to consider that each part of the mold is simple to process, easy to operate, and easy to assemble by the fitter, etc., so as to save processing time and reduce costs.

.jpg)

.png)