Five-axis machining technology marks a major leap for the manufacturing industry, moving from traditional three-axis methods to advanced machining. It enables the production of complex, multi-angled parts in a single setup, significantly boosting both efficiency and precision. However, to fully unlock the potential of five-axis machining, companies need more than just costly equipment—they also require skilled operators, rigorous process management, and the support of smart manufacturing technologies such as AI, automation, and digital simulation. Looking ahead, five-axis machining will continue evolving toward greater precision, environmental sustainability, and hybrid manufacturing, integrating sustainable principles to help businesses strengthen their competitiveness. Overall, five-axis machining is not merely an equipment upgrade, but a comprehensive transformation that blends technology, talent, and management—mastering these elements will be the key to business success.

From Three-Axis to Five-Axis: A Major Leap in Machining Technology

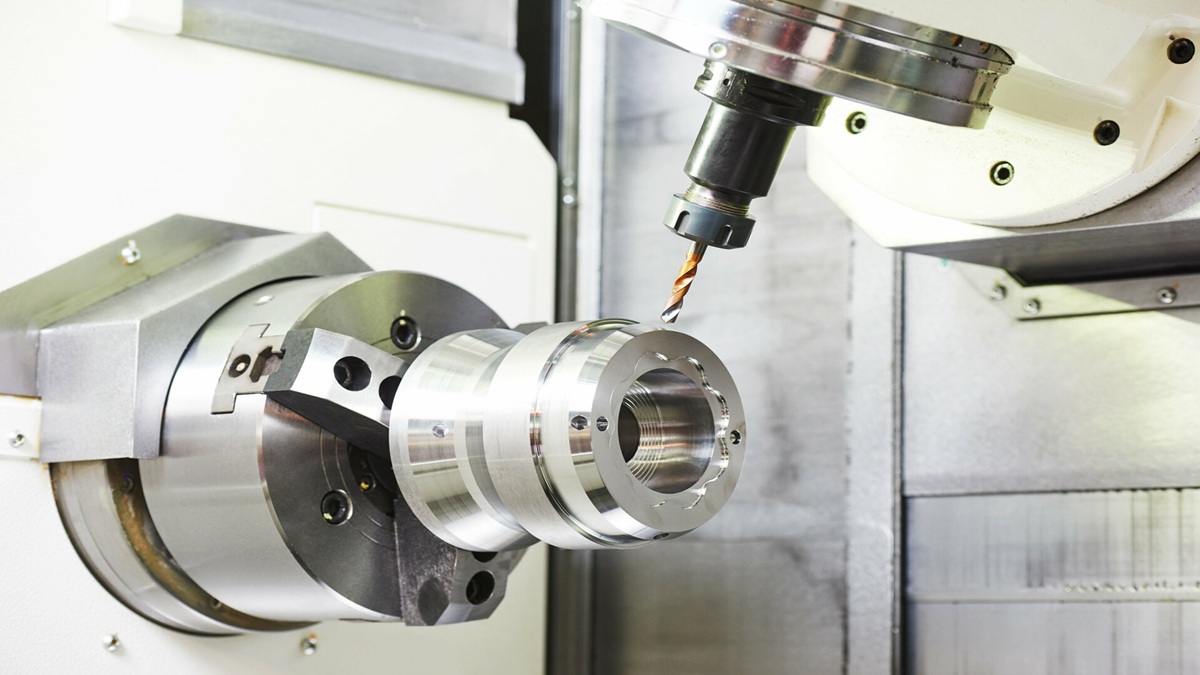

Have you ever wondered how parts with highly complex shapes and extreme precision requirements—like aircraft turbine blades or medical implants—are actually made? In the past, traditional three-axis machining centers allowed the cutting tool to move only along the X, Y, and Z directions. When working on curved surfaces or angled features, the part had to be repeatedly flipped and re-clamped, adjusting the angle for each pass. This process was not only time-consuming and inefficient but also prone to errors.

A five-axis machining center, on the other hand, is like having two extra “rotating hands” (commonly referred to as the A-axis and B-axis) that allow the cutting tool to approach from virtually any angle. This means it can often complete in a single setup what used to take multiple operations. For complex parts with hard-to-reach “dead angles,” it’s nothing short of a game-changer.

Take turbine blades in aircraft engines as an example. In the past, they had to be painstakingly flipped and gradually shaped. Now, with five-axis machining, a single clamping can get the job done—achieving precision down to the micron level while dramatically boosting efficiency. For industries like aerospace, automotive, and medical devices, this is more than just an upgrade in machining methods—it’s a decisive factor in quality and competitiveness.

Current Challenge: Having Five-Axis Capability Doesn’t Mean It’s All Smooth Sailing

Five-axis machining sounds impressive, but fully unlocking its potential is far more complex than it appears.

For starters, a five-axis machine is a major investment, often costing several million NT dollars. But the real challenge isn’t just being able to afford one—it’s knowing how to use it well. Compared with three-axis machining, five-axis requires a much higher level of skill in both operation and programming. It’s not a “push-button” process you can master overnight.

If the programming isn’t done correctly, not only will the machining quality suffer, but there’s also a risk of the cutting tool colliding with the workpiece or even the machine itself, leading to costly damage. To prevent this, a complete toolpath simulation must be carried out before machining, checking step by step for possible interferences or collisions—because even the smallest oversight can result in total failure of the job.

On top of that, many commonly used materials today are increasingly “difficult” to machine—such as titanium alloys, ceramics, and carbon-fiber composites. These materials are not only extremely hard and challenging to cut, but they also accelerate tool wear and can even cause tool breakage. This puts tremendous demands on both the equipment and the technical capabilities of the team.

Adding to the pressure, customer requirements are constantly rising: dimensional tolerances often need to be kept within 0.01 mm, while still maintaining stable, high-volume production. This means success isn’t just about owning the machine—it requires highly skilled engineers, robust process control, and continuously refined machining strategies to build true, reliable five-axis capability.

In other words, five-axis machining isn’t a case of “buy the equipment and you’re set”—it’s an all-round upgrade challenge, spanning technology, talent, and process excellence.

The Rise of Smart Manufacturing: AI × Automation × Simulation

In the face of these challenges, traditional machining methods are proving increasingly inefficient and impractical. The good news is that smart manufacturing technologies are offering fresh solutions for five-axis machining.

First comes AI (Artificial Intelligence). By leveraging big data analytics, AI can optimize toolpath parameters and automatically calculate the most efficient cutting routes, effectively reducing the risk of tool collisions. At the same time, AI can continuously monitor machine operation data—such as vibration, temperature, and spindle load—to enable predictive maintenance. The system can proactively alert operators when it’s time to replace a tool or perform maintenance, preventing unexpected downtime.

When combined with automation—such as AGVs (Automated Guided Vehicles) for loading and unloading, or the integration of Flexible Manufacturing Systems (FMS)—entire production lines can achieve higher flexibility and stability. Even with high-mix, low-volume production demands, operations can continue seamlessly without interruption.

Furthermore, with modern CAM software and Digital Twin technology, companies can perform complete virtual simulations and toolpath verification before actual machining begins. This not only saves on trial-cutting costs but also greatly reduces the risk of errors.

These smart technologies—from AI optimization, robotic collaboration, and automated material handling, to virtual simulation—are more than just tools; they are key drivers of manufacturing transformation. They give companies the confidence to step into the field of high-complexity part production, while shortening development cycles, improving quality consistency, and accelerating the journey from merely “operating five-axis” to truly “mastering five-axis.”

Moving Toward the Future: Precision, Sustainability, and Hybrid Manufacturing

Looking ahead, five-axis machining will continue evolving toward greater precision, sustainability, and process integration.

First, as industries such as medical electronics and micro-electromechanical systems (MEMS) see growing demand for miniaturization and ultra-high accuracy, five-axis machining—combined with ultra-precise tooling—will become a critical solution for producing intricate, micro-scale components that meet the market’s stringent standards for detail and quality.

Second, hybrid manufacturing technologies are on the rise, combining additive and subtractive processes. In the future, a single machine may first use 3D printing to create a near-net shape, then follow up with milling for precision finishing. This integrated approach not only reshapes production workflows but also increases flexibility and accuracy in part manufacturing.

Finally, as global emphasis on green manufacturing intensifies, carbon emissions and energy efficiency are becoming metrics companies cannot afford to ignore. More manufacturers are investing in high-efficiency servo motors, coolant recycling systems, and even energy recovery mechanisms designed into facilities from the planning stage. With IoT-enabled energy monitoring, production processes can be continuously optimized, driving the manufacturing sector toward sustainable operations.

In the years ahead, companies aiming for competitive advantage will need to balance speed and cost with environmental responsibility—embedding resource circularity into their workflows to build manufacturing systems that align with sustainable development goals.

From Technology to Strategy: Five-Axis Machining Is More Than Just a Tool

Overall, five-axis machining is not just an equipment upgrade—it’s a pivotal gateway for companies moving toward advanced manufacturing. For any manufacturer, investing in five-axis technology also means committing to building “soft power” such as talent development, data management, and sustainable operations.

In other words, true success doesn’t rely solely on the machines themselves, but on simultaneously enhancing team expertise, optimizing process management, and effectively leveraging data resources. Only by mastering the full integration of people, systems, and workflows can five-axis machining deliver its greatest value to a business.

Looking ahead, companies that embed this transformative mindset into their strategic planning will be well-positioned to seize opportunities and gain a competitive edge in the high-complexity manufacturing market.