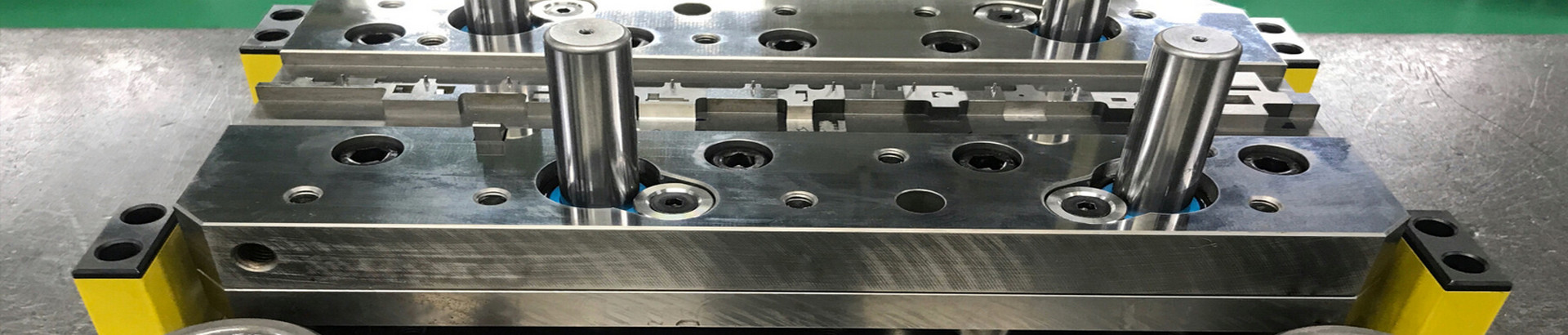

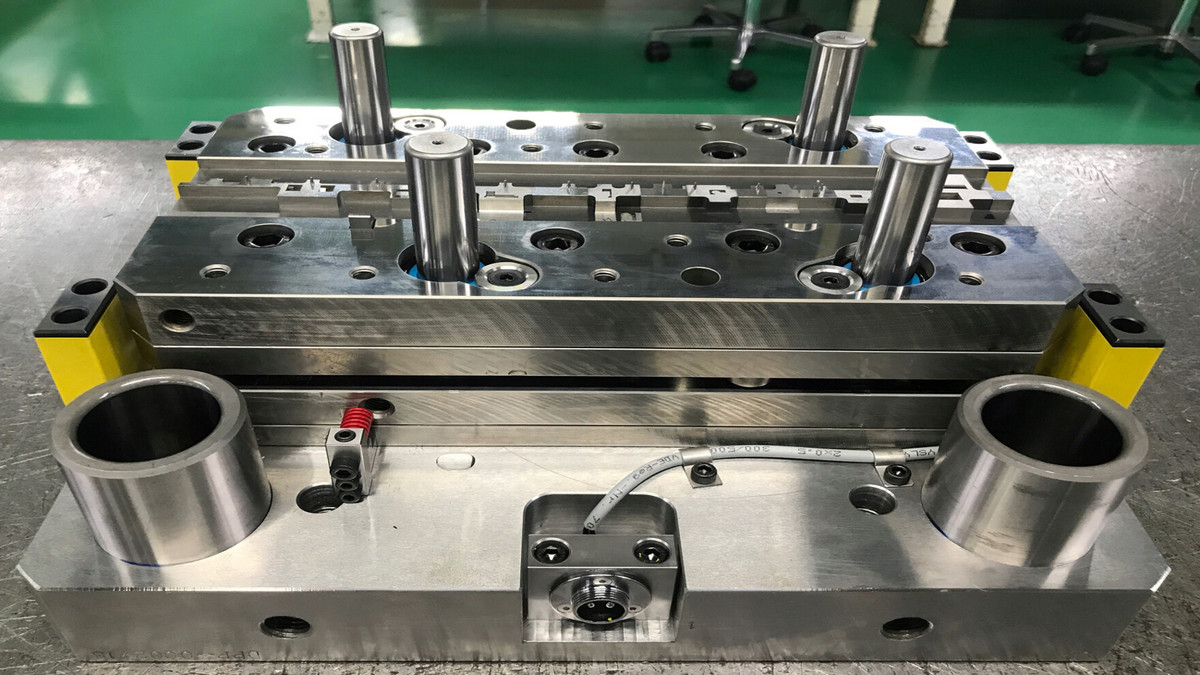

A stamping press machine is a machine that can process sheet metal into the desired shape. It is commonly used for metal stamping to convert a flat metal sheet into a specific shape. What are the types of punching machines? Let's dig it out!

What Is A Stamping Press Machine, or Stamping Press?

A stamping press machine is a machine that can process sheet metal into the desired shape. It is commonly used for metal stamping to convert a flat metal sheet into a specific shape. It can include a variety of metal forming techniques: blanking, punching, bending and perforating. A stamping press machine, also known as stamping press, or simply press machine, is a specific type of machine tool that is often used in metal forging to transfer energy through a certain distance and force.

What Are the Types of Punching Machines?

Hydraulic Press: Hydraulic press machine uses liquid pressure to release energy, and valves to increase or decrease the pressure of a liquid in the chamber. Hydraulic presses are more common than other types, but on the other hand, hydraulic presses are the most powerful punches. The machine can apply 75,000 tons of power, even higher. The working principle is that depending on the difference in fluid pressure, the liquid can be injected or reduced above or below, and the pressure is changed to allow the piston to rise or fall.

Mechanical Press: The mechanical press machine atmosphere has a wider variety of machine types, which convert the rotational force of the motor into pressure acting on the object. Mechanical presses are characterized by rapid and continuous application of pressure over a limited distance, often used for metal forging or sheet metal processing. The pressure of mechanical punching machines can reach 12,000 tons.

Crank Press: The crank press moves together with the driveshaft and rotates back and forth to transmit the force to the object. The transmission path of the crank press is long.

Knuckle Press: Through the connecting rod design, the huge energy of the motor can be transmitted.

Rack and Pinion Press: Through the movement of gears and racks, the transmission of energy is driven.

Screw Press: By rotating the screw, the energy of the rotation is driven, and the pressure is applied. The screw press operates slowly and can generate a relatively large constant force.

The stamping press machines can meet the needs of mass production and has a fast turnaround time, high quality and low cost. Pick the right type of stamping press regarding different needs would make forging easier.

.jpg)

.png)