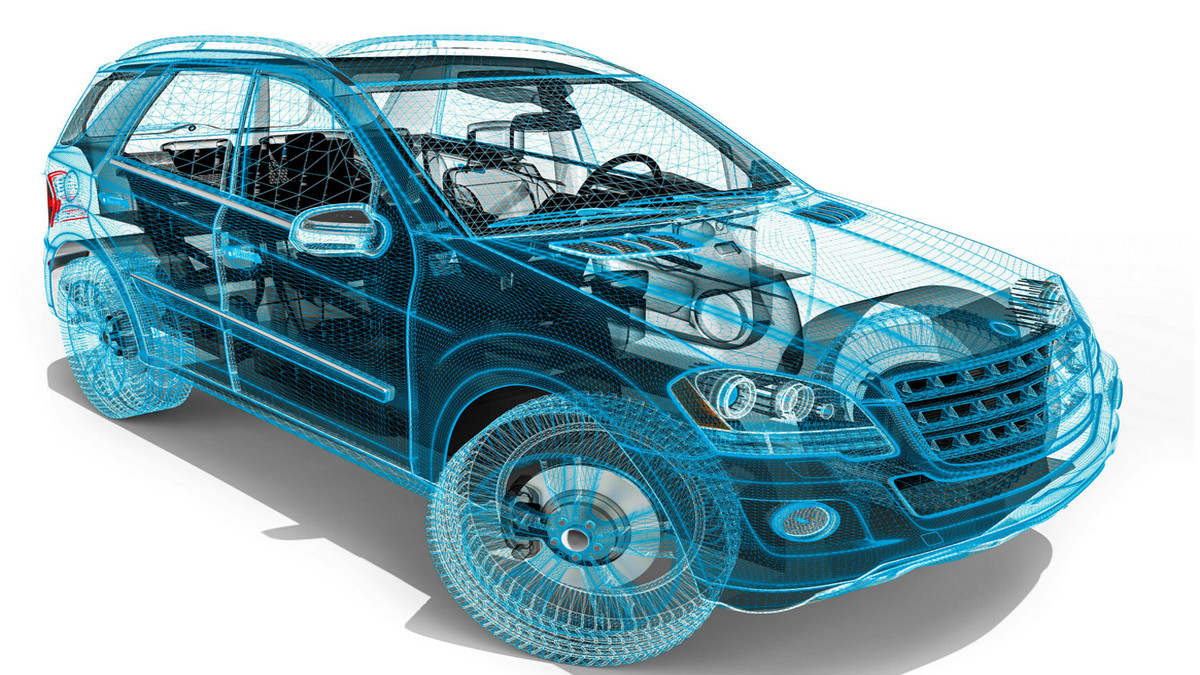

What Are the Commonly Used Auto Parts?

Taiwan’s automobile manufacturing industry is mainly dominated by "auto parts manufacturing", which accounts for about 60% of Taiwan’s automobile industry production. Taiwan’s auto parts manufacturing industry consists of mainly small and medium-sized enterprises that focus mainly on supplying the after-sales market. Taiwan's auto parts production has a high degree of diversification and flexible manufacturing. It has strong international competitiveness and potential to enter the supply chain of international automakers.

Taiwan's auto parts manufacturing is known for its ability to provide small quantities and extensive variety of automotive parts such as plastic parts, lights, bumpers, forged die castings, hoods, etc. Taiwanese manufacturers have a well-integrated supply chain including upstream components manufacturers, midstream integrated systems and products assembly, and downstream complete vehicle assembly, repair products and tools, and automotive maintenance and service.

What Are the Commonly Used Automobile Parts?

In addition to the parts frequently used in automobiles, key assembly system tools and machines such as equipment for engine assembly, transmission assembly, as well as components used for the production of auto parts, are also considered part of the auto parts industry. Raw materials that directly affect the development of the automobile industry, such as plastics, metals, glass, and paints, are also considered as auto parts or components.

- Engine parts: Automobile engine parts mainly include pistons, piston rings, cylinder head gaskets, gaskets, valves, fuel pumps, electronically controlled fuel injection pumps, etc.

- Electrical and electronic devices: The main components are starters, alternators, spark plugs, engine control devices, electronic devices for braking systems, electronic components, and sensors.

- Lighting, instrumentation, and electrical and electronic equipment: the main components are headlamps, speedometers, wiper motors, other motors, various switches, steering locks, wiring harnesses, etc.

- Parts of power transmission devices and control devices: the main components are clutch plates, manual transmissions, automatic transmissions, power steering devices, transmission shafts, wheels, transmission joysticks, etc.

- Suspension and braking device components: The main components are leaf springs, shock absorbers, and braking devices (brake drums, brake discs, brake power devices, brake hoses, etc.)

- Body parts: The main parts are the frame, fuel tank, window frames, door handles, door locks, seat springs, seat belts, etc.

- Auto accessories: These include clocks, tape recorders, air-conditioning devices, heating devices, wheel covers, paint for repairs, car stereos, etc.

- Steering accessories: This mainly includes kingpins, steering gears, steering assemblies, etc.

- Suspension system accessories: Mainly include rear axle, air suspension system, balance weight, steel plate, etc.

- Car accessories: Mainly includes tire pumps, car top boxes, car top frames, electric winches, etc.

- Security and anti-theft accessories: These mainly include steering wheel locks, wheel locks, cameras, etc.

- Car interior accessories: Mainly includes carpets (foot pads), steering wheel covers, steering wheel power balls, curtains, sun gear, etc.

- Automotive exterior accessories: Mainly includes wheel covers, body-color stickers, license plate holders, etc.

- Comprehensive accessories: Mainly includes adhesives, sealants, vehicle tools, automotive springs, plastic parts, etc.

- Audio-visual electrical accessories: Mainly includes tire pressure monitoring systems, decoders, displays, car walkie-talkies, etc.

- Chemical and physical accessories: Mainly includes coolants, brake fluid, antifreeze, lubricating oils, etc.

- Auto body and accessories: Mainly includes wipers, automotive glass, seat belts, airbags, instrument panels, etc.

- Auto repair parts: Mainly includes sheet metal equipment, purification systems, tire changers, calibration instruments, etc., as well as electric punching shears, heat guns, electric jacks, electric wrenches, and other electric tools.

- Auto electrical accessories: Auto electrical accessories are one of the most important parts of a car. These mainly includ batteries, battery clips, battery cables, cable ties, starters, magnetic switches, unidirectional devices, rotors, stators, carbon brushes, carbon brush holders, copper sleeves, bearings, starter relays, ignition switches, regulators, engines, wiper motors, heater motors, heater resistors, heater switches, wiper intermittent relays, wiper switches, headlights, lights, fog lights, tail light assemblies, brake light switches, reversing light switches, light switches, fog light switches, double flash switches, various relays, light bulbs, wiper blades, flashers, GPS/navigation, GPS accessories, and other electronic equipment.

How to Extend the Service Life of Auto Parts?

As you can see, there are quite a lot of auto parts in a car. If they are not used properly, the service life of these auto parts will be greatly shortened.

- Paying close attention to the temperature of the engine is extremely important. If the piston temperature gets too high, the resulting expansion and heat can cause serious and permanent damage to the engine.

- V-belts, rubber seals, and tires will have problems with aging, shortened service life, and reduced performance if they become overheated.

- If the coils of electronic equipment such as regulators, generators, and starters in auto parts are overheated, they can cause shorts and burning.

- When installing the engine cylinder head gasket, it cannot be installed inverted, otherwise, it will cause burning and damage to the engine and other parts.

- The engine fan blades also cannot be reversed when mounting.

- When tires are installed, the tread patterns marks on the ground should have the chevrons pointing to the rear of the vehicle.

- Air filters, oil filters, fuel filters, hydraulic oil filters, and parts of respective filters should all be kept clean and changed regularly.

- If the engine block and cylinder head radiator, water tank radiator, cooler radiator, and other auto parts become obstructed with dirt, it will lead to poor heat dissipation, which will make the temperature of the engine too high, affecting performance and service life.

- Engine valve locks should be installed in pairs, if they are not matching, they will cause the valve to run irregularly and may damage the pistons or other parts.

- Engine connecting rod bolts, flywheel bolts, cotter pins installed on drive shaft bolts, locking screws, safety sheets or spring washers, and other anti-loosening devices, once installed should never be removed as it may lead to serious failures in use.

- If the oil nozzle used to lubricate the gears in the engine timing gear chamber is missing, it will cause serious oil leakage.

- Never use oil to clean the paper air filter element.

- Never use oil or petroleum products to clean leather parts.

- If the paper filter element of the engine air filter is stained with oil, it can restrict air flow causing the carburetor to draw a higher fuel concentration into the cylinder, resulting in increased fuel consumption, and reduced engine power.

- If brake shoes become stained with oil, they can threaten driving safety.

.jpg)

.png)