Do you know how the plastic products are made in our daily living? Bottle caps, bowls, auto parts, etc. Many of the plastic products that are common in life are injected by injection molding machines. When it comes to injection molding machines, many people should have no idea in their minds. Injection molding machines can manufacture limited to plastic products. In this article, we sort out the common injection molding machines with the different characteristics of different models? Let's take a look at the following.

What is An Injection Molding Machine?

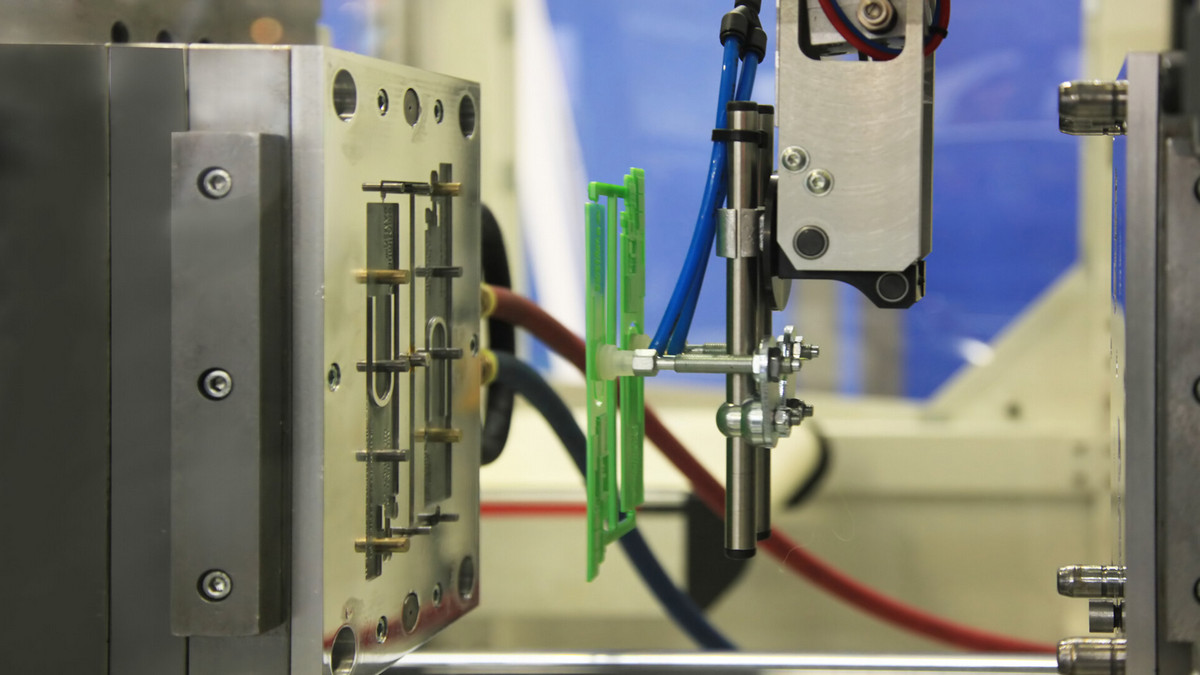

Injection molding machine is a special machine for manufacturing plastic products. Most injection molding machines are mainly composed of two parts: injection device and clamping unit. The injection unit is responsible for heating the poured plastic pellets to turn them into liquid. The clamping unit is used to carry the mold and provide the force required for closing and clamping the mold. Generally speaking, the injection machine has the advantages of fast processing and economic benefits.

What are The Types of Injection Machines?

There are many types of injection molding machines, which can usually be distinguished by the following methods:

Classification Method 1: Drive Method

Hydraulic Injection Molding Machine

The injection power of the hydraulic injection machine is mainly hydraulic. The characteristic is that the machine is relatively cheap. It can also be used to make larger appliances such as automobile bumpers and multi-piece molds. However, the disadvantage is that the cost of machine production and maintenance is high. Because the hydraulic plastic injection molding machine cannot be idle, it needs to keep running all the time, otherwise the machine may break down; while making plastic components, it is also necessary to control and adjust the temperature of the machine, otherwise it is easy to produce scrap products.

All Electric Injection Molding Machine

Compared with the hydraulic injection machine, the price of the all-electric injection molding machine is higher, but the all-electric injection machine does not need to be in standby mode, nor does it need to adjust the temperature, so the injection molded products are relatively stable and can be more efficient for injection products, the all-electric injection machine does not have a hydraulic system, and there is no risk of liquid leakage in the machine.

Hybrid/Servo Hybrid Injection Molding Machine

The oil-electric compound injection machine has the characteristics of high efficiency and economic benefits. It is a modified model that integrates the advantages of the hydraulic type/all-electric type. It is a plastic injection machine used by many companies now, and it balances the other two advantages and disadvantages of hydraulic presses, there are medium machine costs and energy costs. We all know that when choosing an injection molding machine, energy cost is definitely a major consideration when purchasing. For this, the servo oil-electric injection machine is equipped with a high-precision servo motor to achieve the same cost-effectiveness as the all-electric type. Considering the cost of electricity, the machine table and mold clamping mechanism are also simpler, more accurate and more durable, greatly reducing the cost of maintenance. The servo hybrid type not only has the advantage of cost saving, but also has higher injection and holding pressure than the all-electric type, which is a major breakthrough in the hybrid injection molding machine.

Classification Method 2: Trends of Switch Mode

Vertical Injection Molding Machine

As the name implies, the vertical injection molding machine is an upright injection molding machine. It is usually used to make relatively small molds. It has the advantages of being able to inject more types of products and saving space. If the vertical injection machine is equipped with a rotary table or a conveyor belt, It can effectively improve production efficiency.

Horizontal Injection Molding Machine

Horizontal injection molding machine is the most widely used and used by the most people. It is characterized by relatively low body, fast molding, and convenient operation and maintenance. The characteristic of the machine is that the plastic parts will automatically fall after being pushed out, so it can reach automatic production.

Classification Method 3: Applicable Raw Materials

Thermoplastic Injection Molding Machine

Thermoplastics melt into liquids when heated, and return to solids when cooled. Common thermoplastics include PE, PP, ABS, TPU, etc. Generally, most of the plastics that soften when exposed to heat are thermoplastics. Thermoplastic injection machines use the characteristics of thermoplastics to inject liquid plastic into the mold after the plastic pellets are heated. After cooling, the plastic turns back to a solid state, and then the plastic parts are pushed out of the machine.

Thermosetting Plastic Injection Molding Machine

The characteristic of thermosetting plastic is that it will change from liquid to solid after heating. This transformation can only be molded once, and it cannot be recycled and reused like thermoplastic plastic, so it is not environmentally friendly. Common thermosetting plastics include FRP and melamine. The thermosetting plastic injection machine injects the plastic liquid into the mold after being processed, and makes the plastic parts solidify after heating to complete the production.

Powder Injection Molding Machine

Powder injection molding can also be called "metal injection molding" (MIM), "ceramic injection molding" (CIM). Raw materials are finely processed metal or ceramic powders and bonding materials. Common applications are portable products, smart devices, electronic products, etc. Powder injection is often used to manufacture small parts with high precision and complex shapes, especially metal. The parts injected by powder have the characteristics of high strength and high density. After the metal powder and bonding material of the powder injection machine are processed, they will become fine molding materials similar to plastic particles, and then the injection molded workpiece will be cleaned, heated, etc. Post-processing, and finally complete the production of the workpiece.

Classification 4: Mode-Locked Structure

Single Cylinder/Double Cylinder/Four-Cylinder Direct Pressure Injection Molding Machine

The direct pressure injection machine is also divided into different models such as single cylinder, double cylinder and four cylinder according to the number of hydraulic cylinders. Because the area of the single-cylinder type hydraulic cylinder is large, the production of parts will be more difficult, so there will be many problems when the single-cylinder type is used in a large-scale machine, and because the single-cylinder type usually directly presses on the mold, so the mold accuracy is very important. Insufficient precision will directly affect the accuracy of mold clamping. At present, single-cylinder direct pressure injection machines have been gradually replaced by multiple-cylinder direct pressure injection machines. Double-cylinder injection means that two cylinders perform injection in parallel. Usually, the injection speed of the double-cylinder is slower than that of the single-cylinder under the same pressure, but the injection pressure will increase. The platen design of the four-cylinder direct pressure mold clamping is different, and the oil cylinder also has the function of automatic balance correction, so it does not affect the precision of the mold clamping, and the scope of application is relatively wide. In the past, the most common problem with the four-cylinder direct-pressure mold clamping machine was unbalanced force, which resulted in mold damage and product size that could not meet the requirements. However, most of these problems can be greatly improved as long as the parts are processed accurately enough. Compared with the toggle type, the mold life of the direct pressure type is very long, the mold can be directly locked, there is no resistance when moving, so there is no need for frequent lubrication, and the maintenance cost is low. Although the machine is more expensive than the toggle type injection molding machine, the characteristics is more durable than the toggle injection machine.

Toggle Injection Molding Machine

The toggle type injection machine is characterized by acceleration and deceleration functions, simple operation, lower operating cost and machine cost. Compared with the direct pressure type, the mold and machine life of the toggle type are shorter. The structure is also more complex.

Compound Direct Pressure Injection Molding Machine

The components injected by the compound direct pressure injection machine are the same as the direct pressure type. The longer machine has a larger mold opening force, and a relatively long clamping stroke can be designed, but the mold clamping structure is more complicated, and because of the complex structure, for the durability of components is a big challenge, and currently only a few manufacturers produce in large quantities.

Classification Method 5: Injection Structure

Monochrome Injection Molding Machine (One-set Injection Single-Component)

Monochromatic injection means that the entire plastic component is of the same color during injection. Monochromatic injection is the injection machine most people use at present. Monochromatic injection can also be used to inject products with two different colors. The color injection molding machine injects the first semi-finished product with the first color, and then processes the semi-finished product with the second color to complete the production.

Multi-color Injection Molding Machine (Multi-Component Injection)

Multi-color injection machines can simultaneously inject plastic components with two or more different colors. At present, the most widely used multi-color injection molding machine is a two-color injection molding machine. After years of improvement, multi-color injection molding has also developed sandwich injection, cube molds, or it is an application combined with LSR silicone rubber. In recent years, multi-color injection technology has gradually become a hot trend in the industry due to its environmental protection, high efficiency, and good performance.

Conclusion

With many injection machines are introduced above, do you have a preliminary understanding of plastic molding machines? If you are wondering which injection molding machine should be used for the product you want to produce, you can first think about the characteristics of the product, the company's budget, usage and long-term durability. Each type of injection molding machine has its advantages and disadvantages. Pick one with your needs!

.jpg)

.png)