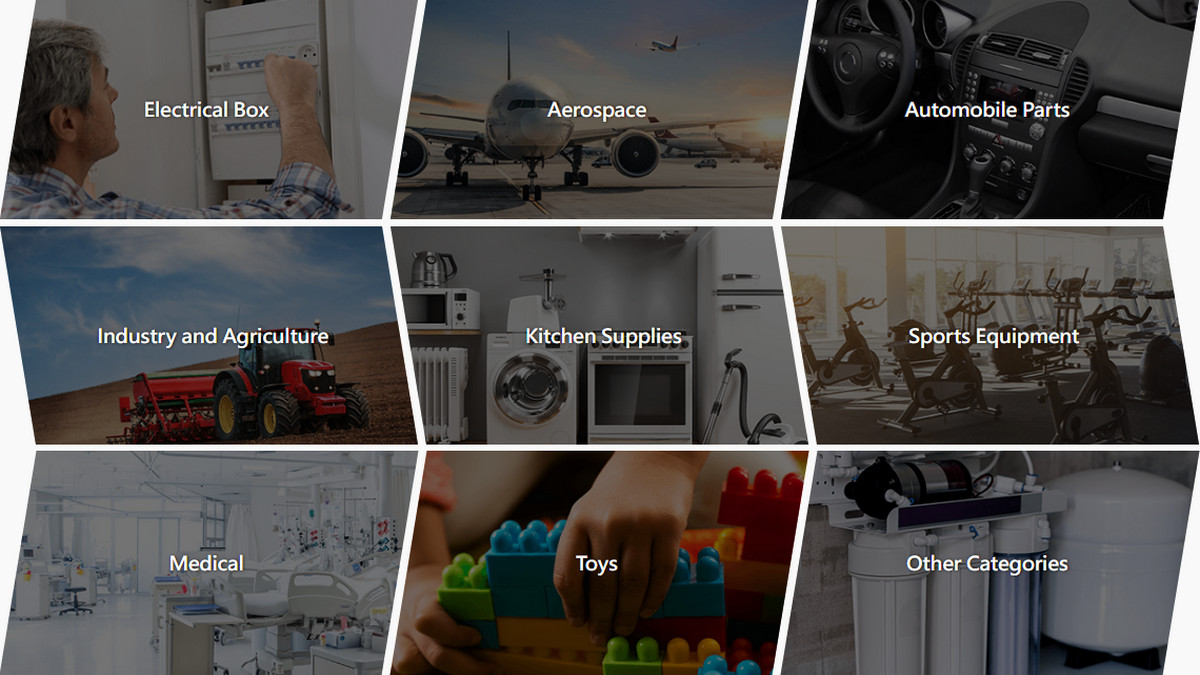

For companies seeking a trusted and innovative plastic injection manufacturer, the importance of high-quality and reliability cannot be overstated. These products, used in various industries such as automotive, kitchenware, medical equipment, sports equipment, agricultural machinery, and toys, play a crucial role in the production and functionality of numerous items we encounter daily. With over four decades of expertise, YHY is well-equipped with fully automated, state-of-the-art production lines to meet the diverse needs of its global clientele.

The Importance of High-Quality in Plastic Injection Products

Plastic injection molding is a critical process in manufacturing parts that require precision, durability, and cost-efficiency. The quality of plastic components can significantly impact product performance and user safety.

Automobile and motorcycle parts, such as engine components and structural elements, must withstand high temperatures, vibrations, and stress. Kitchen utensils and medical equipment demand materials that are safe, hygienic, and durable. Similarly, sports equipment and agricultural machinery rely on plastic parts that are both lightweight and strong, able to endure constant use and exposure to the elements.

Qualities to look for in plastic injection products include:

Precision: Tolerances must be met to within fractions of a millimeter to ensure parts fit and function correctly.

Material Quality: The use of engineering plastics and other high-performance materials that can withstand extreme temperatures, pressures, or exposure to chemicals is critical.

Durability: The longevity of the product, especially in high-stress environments, must be ensured through rigorous material selection and design.

Cost-Effectiveness: High-quality plastic injection manufacturing should also be cost-efficient, balancing production costs with superior performance.

Yeh Her Yow Innovation and Quality

Advanced Mold Flow Analysis

One of the key advantages of working with Yeh Her Yow is their advanced mold flow analysis. This technology allows for the design and development of optimal mold structures, ensuring the best conditions for production molding.

Yeh Her Yow offers a comprehensive production service, covering everything from mold development to packaging, assembly, and surface decoration. Their OEM/ODM mold manufacturing department helps clients create high-quality molds for plastic injection, tailored to their specific product requirements.

With over 20 production lines, each fully equipped with robotic arms, Yeh Her Yow guarantees stability, high quality, and efficient mass production. Advanced plastic injection machines ranging from 100 to 1500 tons are capable of handling projects from the minutely detailed to the massively scaled. This one-stop-shop approach simplifies the production process for customers, allowing them to focus on their product design and functionality, while Yeh Her Yow handles the structural and production aspects.

Material Customization

Understanding the critical role materials play in product design, YHY offers a variety of high-specification specialty materials tailored to meet specific customer needs. They excel in manufacturing high-performance engineering plastics capable of withstanding extreme conditions, from temperatures as low as -80 degrees Celsius to as high as 350 degrees Celsius, and offering resistance to chemical exposure. This makes them ideal for demanding applications such as aviation parts, medical equipment, and automotive components.

Smart Production for a Smart Future

Embracing the future, YHY incorporates intelligent networking of equipment and big data analytics into its production processes. This smart production setup not only improves efficiency but also enhances the quality of products through continuous monitoring and updates, ensuring YHY stays ahead in a competitive market.

Global Vision with a Local Touch

Taiwan is renowned for its expertise in precision manufacturing, particularly in the plastics industry. Taiwanese manufacturers are known for their high-quality products, advanced technology, and competitive pricing, making the country a global leader in plastic injection manufacturing. Yeh Her Yow has a strong presence in both Taiwan and the global market. This blend of local expertise and international outreach makes YHY a trusted partner for well-known enterprises worldwide.

Your Trusted Partner in Plastic Injection Manufacturing

Yeh Her Yow Plastic Co. Mfg. Ltd. is more than just a manufacturer; it is a partner that brings your ideas to life with precision, efficiency, and innovation. Whether you are in the automotive, medical, or any other industry, YHY offers the expertise, technology, and customer-focused service to ensure your projects are successful and your products are of the highest quality.