Since the United Nations announced the 2030 Sustainable Development Goals (SDGs) in 2015, Living Fountain has adopted Goal 12 — Responsible Consumption and Production — as its core mission. By utilizing Post-Consumer Recycled (PCR) materials, the company aims to reduce the burden on the planet, decrease the production of virgin petrochemical plastics, promote industrial circularity, and work persistently toward the goal of carbon neutrality.

Background & Sustainability Strategy

Established in 1991, Living Fountain began with a 3.5cc pump and gradually built its reputation in the packaging industry. Over the years, Living Fountain has focused on product innovation and one-stop procurement services, aspiring to become the most trusted packaging provider.

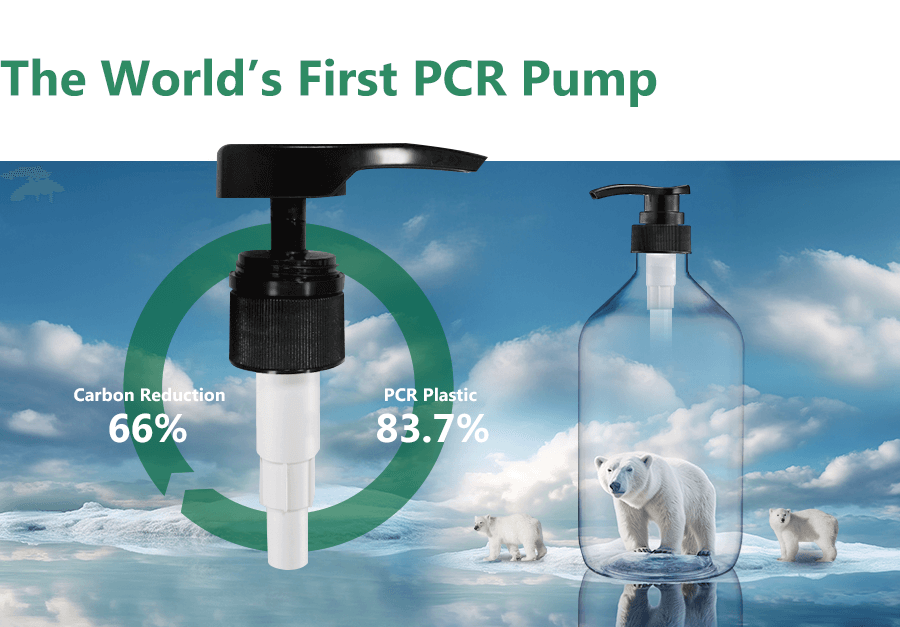

In 2016, the company collaborated with eco-friendly beauty brand O’right to meet specific sustainability requirements. After rigorous testing and parameter adjustments, Living Fountain successfully produced the world's first recycled plastic pump. Made with over 80% recycled plastic, this pump reduces carbon emissions by 66% compared to conventional pumps, becoming a notable, differentiated product in the industry.

This milestone marked a turning point, as Living Fountain shifted its R&D focus to producing green cleaning packaging using PCR materials and established a clean manufacturing process to emphasize the importance of sustainable packaging.

Innovation in PCR Materials and Manufacturing

In December 2019, the European Union pledged to reach carbon neutrality by 2050 and set interim targets for reducing greenhouse gas emissions by 2030 and 2040, pushing the world further toward a low-carbon future. In response, Taiwan’s Environmental Protection Administration set new policies requiring plastic packaging to contain 25% recycled materials by 2025 and 35% by 2030, accelerating material transformation and circular economy implementation.

Living Fountain joined the Taiwan Renewable Energy Initiative, led by Greenpeace, aligning its efforts with national carbon reduction goals and promoting environmental sustainability.

A key step in achieving these targets is reducing the use of virgin petrochemical plastics and shifting to PCR plastics. PCR refers to recycled materials that have been cleaned, shredded, filtered, and decontaminated before being remanufactured into plastic pellets for packaging. While “plastic reduction” is a common environmental goal, the affordability and convenience of plastic make a complete ban unrealistic. Therefore, using certified, reusable PCR materials is a more practical and sustainable solution aligned with circular economy principles.

Expanding the Use of Sustainable Materials

Living Fountain is the first manufacturer in Taiwan to develop a closed-loop B2B tableware recycling service. As countries around the world move to ban single-use tableware, this service not only supports circular production but also provides consumers with safer, reusable alternatives—delivering dual environmental and social benefits.

Tritan Circular Tableware:

Made from safe, high-performance Tritan plastic, these products are non-toxic, heat-resistant, durable, impact-resistant, and crystal-clear in appearance.

CPET Circular Tableware:

Tested by SGS in accordance with U.S. FDA standards, CPET tableware is certified non-toxic and offers excellent insulation, acid and alkali resistance, durability, and a ceramic-like appearance, eliminating the “cheap” impression often associated with plastic.

Sugarcane Fiber Eco Tableware:

Made from upcycled bagasse (sugarcane pulp), this material replaces conventional plastic with a renewable, eco-friendly alternative that significantly reduces environmental impact.

Practicing Sustainability Through Both Products and Corporate Action

Living Fountain is committed to not only fulfilling the SDGs through its products but also integrating ESG principles into its business operations.

Energy Saving & Carbon Reduction:

Replaced all factory lighting with LED panels, reducing total wattage by 24% and saving approximately 10,000 watts annually.

Circular Packaging:

All cardboard boxes were replaced with PP corrugated returnable boxes, reducing carbon emissions by an estimated 337,855 kg per year.

Paperless Operations:

Transitioned all documents to digital formats, saving approximately 664.958 kg of carbon emissions annually.

Energy-Efficient Equipment:

Traditional injection molding machines were replaced with all-electric models, improving production efficiency and achieving 56.5% energy savings.

Circular Progress, Sustainable Commitment

Increasing Use of Recycled Materials:

Ongoing R&D and process optimization aim to further increase the PCR material ratio in products, maximizing resource circulation value.

Expanding the Recycling Ecosystem:

The company is building a comprehensive closed-loop recycling system extending from internal operations to customers and distribution channels, giving packaging a renewed life cycle.

Collaborative Green Supply Chain:

Actively working with upstream and downstream partners to standardize circular packaging solutions and foster industry-wide alignment, making green transformation a collective movement rather than an individual effort.