Many people do not understand what a mold is. A mold (sometimes called a mould) is a block of material with a hollowed-out cavity that has a shape cut into sides of the cavity. Liquid or pliable material is pushed into the cavity where it adopts the shape of the hollowed out section. After the liquid hardens or sets inside the mold, or the pliable material has been pressed into the shape of the mold, the item is removed from the mold. Molds are made from a variety of materials, such as metal, clay, or wood, and can be used to form items out of many types of materials such as plastics or metals.

What is A Mold Used For?

A mold is used to make multiple copies of a desired item. Injection moulding is widely used for manufacturing of small plastic components and punch molding is used to press large sheets of metal into shapes like the entire body panels of cars. Molds are used in the manufacturing of many items used for our daily living.

Molds are divided into metal molds and non-metal molds, according to the different materials they are used to form.

Metal molds are divided into: casting molds, forging molds, die-casting molds, stamping molds, powder metallurgy molds, etc.

Non-metallic molds are divided into: plastic molds and inorganic non-metallic molds.

Plastic molds include: injection molding molds, extrusion molding molds, compression molding molds, suction molding molds, blow molding molds, high foam polystyrene molding molds...etc.

Inorganic non-metallic molds are divided into: sand molds, ceramic injection molding molds, vacuum molds, paraffin molds, etc.

How is A Mold Made?

- Mold design: First an analysis will be made as to whether it will be feasible to produce the demanded product using a mold. An evaluation will be made to determine the best process to use for the mold diagram, taking into consideration the material to be molded and materials required to make the mold.

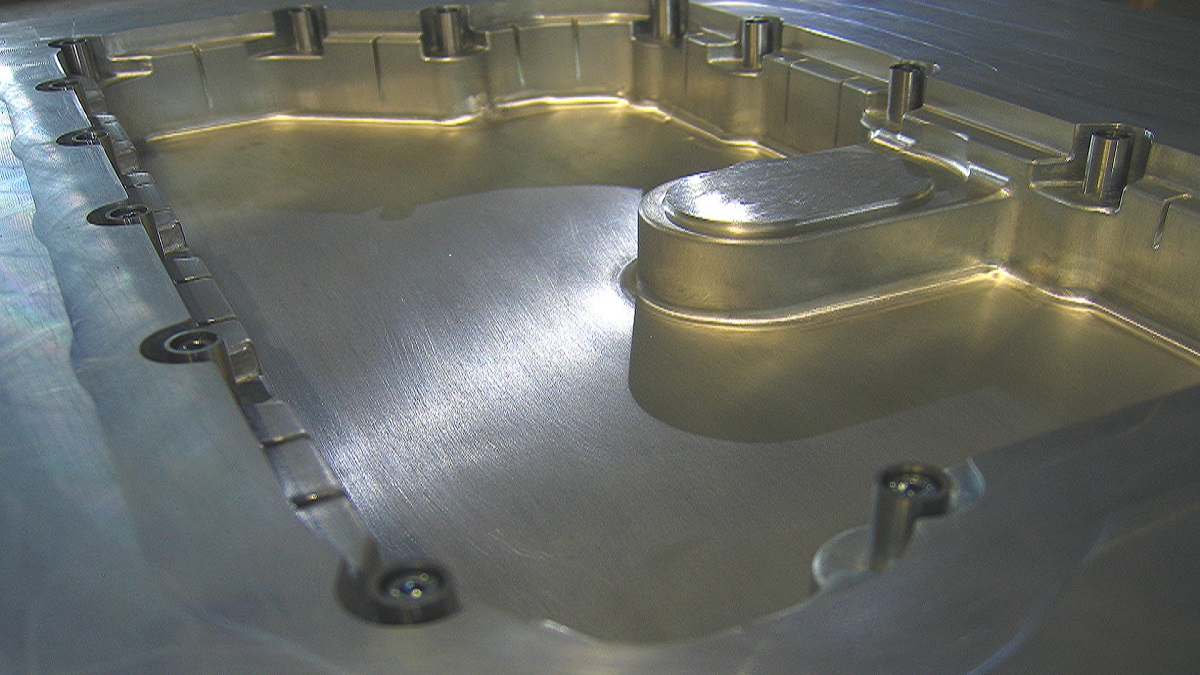

- Mold processing: The mold prototype is cut using machining tools such as lathes, milling machines, grinders, etc., to achieve the shape required for the design.

- Mold testing: After the mold is machined, it is placed on the molding machine for testing and adjusting.

- When the mold has been confirmed, it can now be used to produce multiple copies of the item.

Although there are many types of molds, their functions are similar. It can be said that molds are the mother of industry and a very common tool in modern industry. They are also the core of basic production and have a crucial impact on industrial manufacturing.

The mold is generally separated into two parts: the movable mold and the fixed mold, also referred to as the punch and the concave mold. These two separate parts are placed together during the forming process.

For punch molding a blank is loaded into the cavity of the mold. The mold is closed, pressing the blank against the side of the mold, forcing it to adapt the form of the mold. In punch molding, the external force required for forming is exerted on the blank through the mold.

In the injection molding process, an external force presses the material into the mold, and the sides of the mold bear the expansion force of the blank.

In addition to the mold itself, the molding machine needs a mold base to hold the mold, a guide device, and a part ejecting device. These parts are combined to complete all the processes required to form the completed product.

The application of molds is extremely extensive, and a large number of molds are used in the manufacturing of mass-produced electromechanical products, such as household appliances, automobiles, bicycles, sewing machines, cameras, motors, electrical appliances, instruments, etc.

The mold shape is often complex, and has high requirements for structural strength, rigidity, surface hardness, surface texture, and machining accuracy, so mold production requires a high level of technology. The timely supply and quality of molds directly affects product quality, cost, and new product development. Therefore, the quality of mold production is one of the important indicators of a manufacturer’s capabilities.

.png)