Additive manufacturing is playing an increasingly important role in the manufacturing industry and is mainly used in toolmaking and prototype construction.

Although the terms "3D printing" and "rapid prototyping" are casually used to discuss additive manufacturing, each process is actually a subset of additive manufacturing.

Additive Manufacturing: Definition and Explanation

This manufacturing process is used above all in toolmaking (rapid tooling), in the manufacturing of end products (rapid manufacturing), and in prototype production (rapid prototyping). How can additive manufacturing be classified in terms of manufacturing technologies? Manufacturing technologies are generally based on three pillars:

- Subtractive Processes (something is removed): Milling, lathing, etc.

- Formative Processes (a material is redesigned): Casting, forging, etc.

- Additive Processes (something is added): 3D printing, etc.

Additive manufacturing describes processes in which the part to be produced is constructed by the addition of material. The construction is carried out in layers. This involves the following two aspects:

- The component is made up of different layers. Usually the process is carried out from bottom to top. Simply put, it uses the same principle as for the building of sand castles: A new layer is applied to a building platform in order to build a tower.

- Different processes take place repeatedly in layers (i.e. one after the other). This involves the feeding of the material, the melting (shaping), and finally the bonding with the previous layers. These steps, called the process chain, are the same regardless of which machine is used for additive manufacturing. The only difference is the way the individual layers are created.

Additive manufacturing thus enables the creation of 3D objects. To make this possible, the machine first requires the 3D design specifications ("three-dimensional CAD") of the part to be produced. The respective data set consists of the outline data (length x, height y), the number of layers (z) and the layer thickness (dz). It is the task of the corresponding computer program to divide the model into suitable layers. The software then transmits the data set to the machine in the form of production instructions, e.g. the printer for 3D metal printing.

How Does It Work?

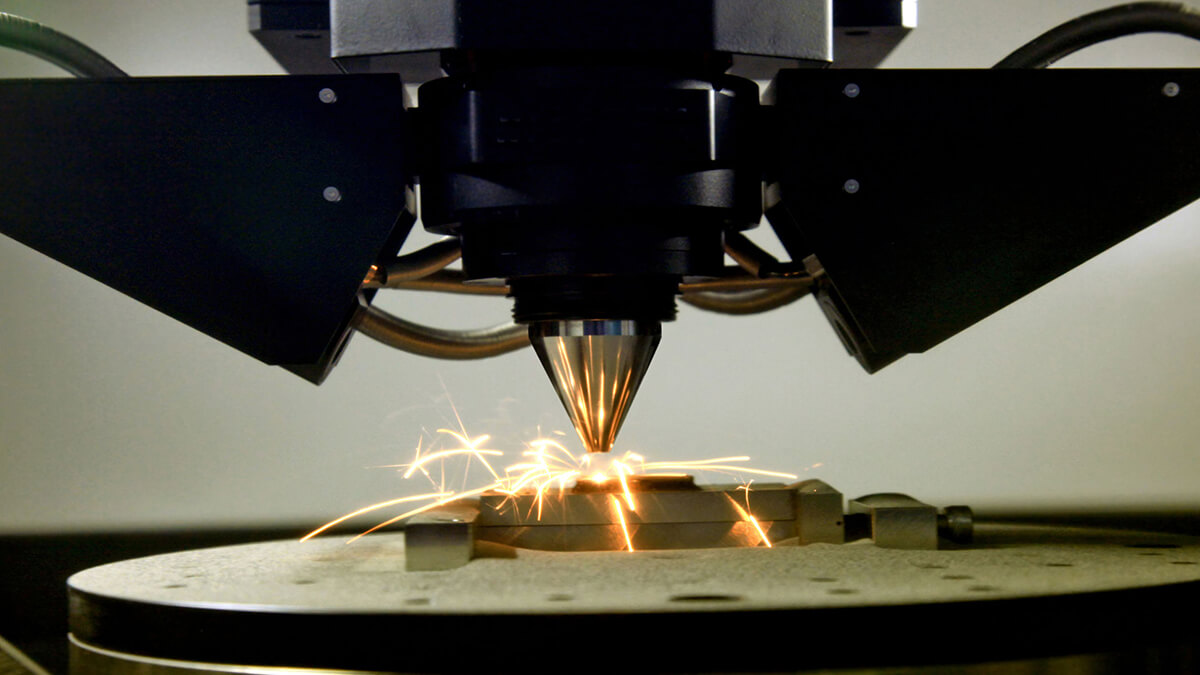

In almost every case, additive manufacturing a uses a powder bed. This means that a powdered material is fed into a bed where it is further processed. In 3D metal printing, for example, a metal (or several metals) is reduced to a powder before it is fed into the chamber and rebuilt. There are four common methods of producing the layers from the powder:

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Electronic Beam Melting (EMD/ EBM)

- Binder Jetting

- SLS: Sintering involves the heating of materials under pressure, but not to the point of melting them. Laser technology makes it possible to create three-dimensional geometries by using undercuts. Usually CO2 or fiber lasers are used to do this.

- SLM: The powder is heated by a high-energy fiber laser and then cooled down. The shape of the components is created by the targeted deflection of the laser beams. SLM is being used more and more frequently than SLS. Since no pressure is applied, the objects exhibit a higher strength and are therefore more durable. This process is frequently used for 3D metal printing.

- EMD/ EBM: In principle, this method is similar to SLM. However, this application uses an electron beam and not a laser beam. The entire process takes place in a vacuum. EMD is faster than SLM, but less precise and has a lower maximum print volume. EMD machines have an average diameter of 350 mm and a height of 380mm. SLM machines are twice as large. EMD is particularly are an ideal additive manufacturing technology whenever small parts have to be produced in large quantities. This process is also often used for 3D metal printing.

- Binder Jetting: The powder is selectively deposited with a liquid binding agent to form the layers. This process has the advantage of allowing a very simple construction in different colors.

The term “additive manufacturing” references technologies that grow three-dimensional objects one superfine layer at a time. Each successive layer bonds to the preceding layer of melted or partially melted material. It is possible to use different substances for layering material, including metal powder, thermoplastics, ceramics, composites, glass and even edibles like chocolate.

Objects are digitally defined by computer-aided-design (CAD) software that is used to create .stl files that essentially "slice" the object into ultra-thin layers. This information guides the path of a nozzle or print head as it precisely deposits material upon the preceding layer. Or, a laser or electron beam selectively melts or partially melts in a bed of powdered material. As materials cool or are cured, they fuse together to form a three-dimensional object.

The journey from .stl file to 3D object is revolutionizing manufacturing. Gone are the intermediary steps, like the creation of molds or dies, that cost time and money.

While additive manufacturing seems new to many, it has actually been around for several decades. In the right applications, additive manufacturing delivers a perfect trifecta of improved performance, complex geometries and simplified fabrication. As a result, opportunities abound for those who actively embrace additive manufacturing.