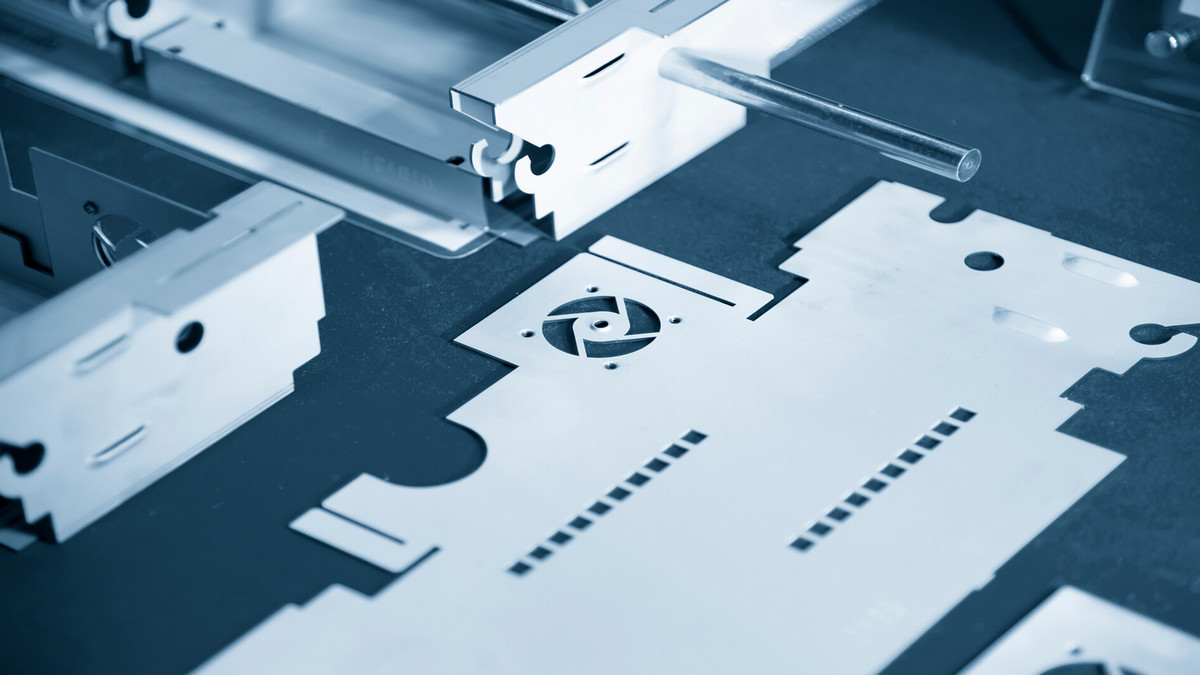

Punching machine, also known as stamping machine, is a forming process technology. There are many types of it. Due to different structural principles, the price and processing effect will be different accordingly, but they all have something in common in terms of structural composition. With the rapid development of the stamping industry, competition in all walks of life is increasing, and it is applied to various industries, such as aerospace, education, auto parts, diving equipment and so on. The following will introduce the punch structure, type and material.

Punching is a common method of metalworking that can be used to transform metal materials into desired shapes, sizes or other properties. Through the punching machine, various complex metal parts can be produced, which greatly improves the production efficiency of the product.

Over the past ten years, as the punch presses have become more functional, the software has become more powerful, and the personnel have developed a very good level of specialization. Therefore, how to use the most advanced CNC punching machine to achieve the best equipment has become one of the key factors to measure the competitiveness of enterprises.

What is A Punch?

Punch press (stamping press), also known as stamping machine, which is divided into manual and pneumatic. It uses preforming dies and pressure to create sheet metal blanks into shaped products and components. Manufacturers use automatic or manual feeders to insert the sheet metal into the punch between the die and the die surface. The press lowers the sheet metal using the compressive force to force the material into the mold to form the desired shape.

Metal stamping is a versatile punching process that produces accurate, uniform products quickly and efficiently. The process is used in both large and small production runs and is often combined with other metalworking processes such as machining, assembly and finishing.

There are many specialized punching techniques that can be used to produce specific effects, including:

- Punching: involves the use of dies and presses to punch holes in workpieces.

- Blanking: punching the workpiece out of the metal slab.

- Embossing: use raised or indented text, graphics, and designs in sheet metal.

- Casting: similar to embossing, but with raised or indented text, patterns, and graphics embossed on both sides of the workpiece.

- Bending: using a bending machine, force is applied to a metal workpiece, which bends the metal workpiece into a V or U shape from its original axis.

- Flange: the edge of the workpiece around the punched hole is bent at a 90° angle to the sheet, forming a lip around each hole.

Working Principle of Punch Press

The working principle of the punch press mainly converts rotary motion into linear motion. The main motor provides the power to drive the flywheel. Through the clutch and connecting rod, the flywheel drives the crankshaft or eccentric gear to convert the surrounding motion into linear motion. There is a need between the slider and the connecting rod. During operation, the driving structure provides power for the up and down movement of the ram, opening and closing the upper and lower molds.

In recent years, in addition to punch processing, various processing modes have emerged, such as 5 axis CNC machining service, vacuum casting, 3D printing, sheet metal processing, etc., especially 5-axis processing is more widely used in various industries. Its processing has the advantages of reducing production time and processing time, and has a single setting function, which can process parts with complex structures and special shapes, and is specially used for processing complex surfaces.

In this process, a metal strip is passed between the die blocks, and as the punch moves down, pressure is applied to the metal plate and a hole is cut, and the separated part falls through the die opening.

Type of Punch

Punch processing equipment is usually divided into three types: mechanical, hydraulic and servo, and the punch process. Punching is divided into progressive die, transfer die, four-piece stamping and fine blanking.

- Mechanical punch

A mechanical punch press has a motor connected to a mechanical flywheel that stores energy to help the machine run. These types of punches can produce punches in a variety of sizes, ranging from 5mm to 500mm, depending on the specific punch used.

Mechanical punches can range in speed from as low as 20 strokes per minute to as fast as 1,500 strokes per minute. At lower speeds requiring extra power, operators can add an auxiliary flywheel to the drive.

The operator of a mechanical press will use electronic controls, clutches and brakes as needed to help engage and disengage the press drive.

Mechanical punching press use: commonly used to make simple parts made of metal lath, often used in high-volume production of transfer and progressive stamping.

- Hydraulic punch

Hydraulic presses use hydraulic oil as the power source, and the technology used in hydraulic presses has improved significantly over time, with each improvement providing upgrades to the electronics and valves.

The fluid released in the hydraulics has a force proportional to the diameter of the punch, which enables highly controlled application of pressure at any given moment.

The pressure used in the hydraulic press can be preset by the user, and the speed at which the slider moves when the mold is closed can also be adjusted, when the normal pressure level is reached, the valve helps to activate the momentum flip to avoid overload.

Application of hydraulic punch press: commonly used to manufacture small and complex parts.

- Mechanical servo punch

A mechanical servo press does not use a flywheel as a power source, instead, it relies on a high-capacity electric motor to complete complex parts at a faster speed than a standard hydraulic press.

Servo punch presses are highly programmable, making it easy to control the forming, slide position, motion and speed of the punch, and these machines run on either linkage assisted drive systems or direct drive systems.

Its high speed and high degree of customization make the mechanical servo press the most expensive option of the three.

- Progressive die punch technology

Progressive stamping does not require multiple machines performing multiple functions and processing functions in one set of operations, a strip of rolled metal is unrolled into a single stamping machine with multiple stations performing individual functions. Each workstation adds to previously completed work, resulting in a finished product.

Progressive stamping simplifies the production of complex parts, reducing production time while increasing efficiency. Since the parts are still attached to the metal rollers, they must be precisely aligned during movement.

Progressive die punching presses are ideal for long runs, as the dies last a long time and do not suffer any damage during the manufacturing process. Like several other punching processes, the progressive die process can be reused, with each job performing a different cut, bend or punch to get the desired shape and design.

- Transfer model punch technology

Transfer model presses are similar to progressive die technology in that they use a mechanical transport system to move parts from one station to another. A mold can be a simple single mold or several mold sections lined up in a row.

Commonly used in tubing applications, frames, shells and structural parts, it has also been developed for larger parts and workpieces and has the benefit of reducing tooling costs.

- Four slide punch technology

Four-slide stamping, also known as multi-slide or four-way stamping, is a process that integrates stamping and forming operations. Ideal for complex builds with lots of bends or twists, this technique uses a tool with four sliders instead of one vertical slider, and then deforms the tool multiple times.

- Precision stamping technology

Precision punching technology provides high precision and smooth edges, usually done on hydraulic or mechanical presses, or a combination of both. A precision press operation consists of three distinct actions:

- Clamp the workpiece or workpiece material in place

- Blanking operation

- Finished part ejection

Precision presses operate at higher pressures than those used in traditional stamping operations, so both tooling and machinery need to be designed with higher operating pressures in mind.

The edge produced by fine blanking can avoid the breakage caused by traditional tools, the surface flatness can exceed other stamping methods, and because it is a cold extrusion technology, it can reduce the overall cost of manufacturing.

Introduction of Punch Materials

Punches can be used to shape a wide variety of metals, both ferrous and non-ferrous. The type of metal chosen depends largely on its intended application as well as the size, shape and design of the product.

- Ferrous metal

Ferrous, ferrous metals are usually magnetic and stronger and more durable. Steel is a well-known ferrous metal with many uses.

Ferrous metals are valued for their high strength, but also because of their higher iron content, which also makes them more prone to rust and corrosion than non-ferrous metals. Of these, carbon steel is the most commonly used ferrous metal in metal stamping applications due to its extremely high tensile strength.

- Non-ferrous metals

Non-ferrous metals and alloys do not contain iron and are therefore not magnetic. Non-ferrous metals are very popular in a variety of stamped products due to their high ductility and wide range of useful properties. The non-ferrous metals most commonly used in punch press applications include aluminum, tin, copper, brass, bronze, gold and silver.

Aluminum is especially popular for stamped parts and products due to its low cost, light strength and corrosion resistance. It is also important to consider the material composition of the die being used when selecting the proper material for your metal punch press.

While most molds are composed of tool steel or hardened steel, different workpiece materials or processes may require alternative mold materials such as aluminum or mild steel.

.png)