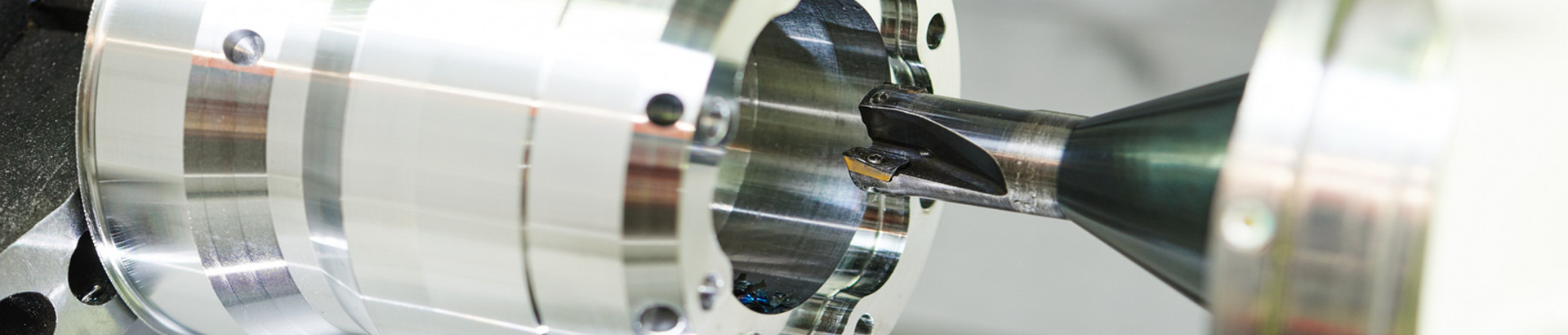

The milling machine is a very diverse processing machine, evolved from a lathe. A lathe is a machine commonly used to produce cylindrical or rotating parts, and the milling machine is commonly used to produce rhomboid or non-rotating parts.

Understanding the Processing Technology of the Milling Machine

A milling machine can accurately milling plane, milling surface, milling groove, milling gear, milling all kinds of complicated shapes. There are many types of milling machines. For example, according to the direction of the tool spindle, there are vertical milling machines, horizontal milling machines, and compound milling machines. The vertical milling machine tool spindle is vertical. In addition to vertical milling, it can also be used for working objects. The main axis of horizontal milling machine tools is parallel to the ground, while the compound milling machine has both vertical and horizontal tool axes.

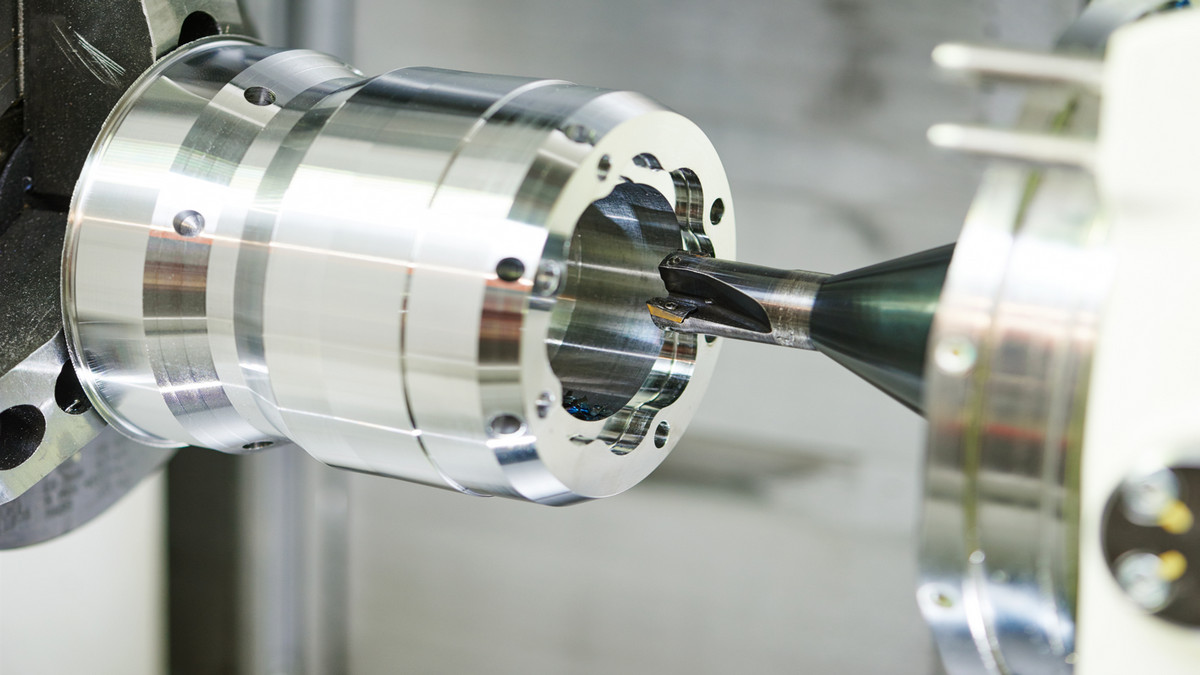

The process of milling is to use the high-speed operation of the milling cutter to contact the work piece to process the work piece into the desired shape and size. In this milling process, the milling cutter cuts the metal material on the surface of the work piece into chips, including the cutting effect of the blade and the pushing and spreading of the blade surface, so that the chips are separated from the processing surface.

The cutting effect of the blade: When the tool is in contact with the work piece, the stress in the work piece gradually increases as the workforce increases, and the stress at the point of contact with the blade edge is the largest. Where the stress is the largest and most concentrated on the work piece, the metal material breaks first and separates. Therefore, the separation of the metal surface layer material and the metal substrate of the work piece is always first formed at the contact with the blade edge, which is the cutting effect of the blade.

Pushing function in front of the tool: Under the action of sufficient mechanical force, as the relative motion of the tool and the workpiece continues, the metal to be cut will be separated along the direction of the blade movement to form a processed surface. At the same time, the squeeze in front of the tool causes elastic deformation and plastic deformation of the cutting layer until chips are finally formed and flow out along the front of the tool. This is the pushing effect in front of the tool.

Deformation of the cut metal under the action of the tool: the cut metal forms four deformation areas under the action of the cutting edge, front and back of the tool, the basic deformation area, the friction deformation area in front of the tool, the deformation area in front of the blade, and the friction behind the tool Deformation zone. The internal stress states and deformation conditions in the four deformation zones are related to each other and affect each other.

Types of Chips and Their Forming Conditions in the Milling Machine

Due to different work piece materials, different cutting conditions, and different deformation during the cutting process, different chips are produced. According to different chip shapes, chips can be divided into four types: band chips, nodal chips, granular chips, and chipped chips.

- Continuous Chip:

During the cutting process, if the slip on the final slip surface has not reached the degree of rupture, a continuous strip-shaped chip with a furry outer surface and a smooth inner surface is formed. Strip chips are the most common type of chips during finishing. When processing plastic metal materials, the cutting speed is high, the thickness of the cutting layer is small, the tool rake angle is large and the cutting edge is sharp, such chips are often produced.

- Nodular chip:

Nodular chip is formed under the condition that the slip on the final slip surface is sufficient and the rupture is reached. Nodular chips have impenetrable cracks, the outer surface is zigzag, and the inner surface is smooth. Most of these chips are produced when processing plastic metal materials, the cutting speed is low, the thickness of the cutting layer is large, and the tool rake angle is small.

- Granular chips:

When the crack penetrates through the entire chip layer and separates the chips into a trapezoidal unit body, granular chips (also called unit chips) are formed. Granular chips are produced when machining metal materials with poor plasticity, at low cutting speed, a large cutting layer thickness, and a small tool rake angle.

- Chipping:

When cutting brittle metals (such as cast iron, etc.), because the plasticity of the material is very small, the metal surface layer will be elastically deformed and minimally plastically deformed by the cutting and pushing of the tool, then it will be brittlely fractured and formed. Crush the chips. The harder and more brittle the work piece, the smaller the tool rake angle, and the greater the thickness of the cutting layer, the easier it is to produce such chips.

.jpg)

.png)