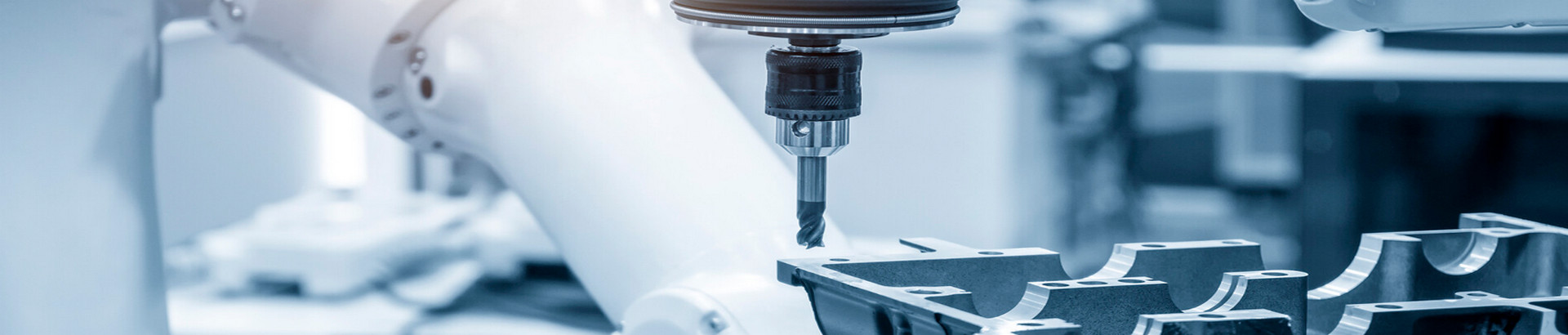

Milling machines provide support to the manufacturing industries. The milling machines can perform almost every milling operation like gear milling, thread milling, angular milling, etc.

What Is A Milling Machine?

The milling machines are used to remove metal from the workpiece to get the desired shape with the help of a revolving cutter called known as a milling cutter. This is used on flat, rough, and irregular surfaces and it is completed by place the workpiece opposite the rotating milling cutter.

The CNC milling machine drives the milling machine through digital signals for processing. The workpiece is moved in the XY plane, and the Z axis is the tool spindle. , which is quite efficient for small or mass production. The milling machine can fix the workpiece, and the rotary tool generally makes 3D or 2D workpieces, which can accurately mill the workpieces in various shapes such as planes, surfaces, grooves, and gears. The advantage of milling is the high metal removal rate when milling workpieces with rotary circular cutters and the ability to cut in a very short time. Due to the different shapes and mechanical application methods of the milling cutters, the milling machine can perform various milling tasks, including plane milling, surface milling, groove milling, gear milling, and cam milling, etc., and can use the forming milling cutter to mill complex contours at one time. Complete with the indexing head can mill the helical groove.

What Are the Parts of A Milling Machine?

The components of milling machine include: Column and Base, Knee, Saddle and Swivel Table, Power Feed Mechanism, Table, Spindle, Over Arm/ Overhanging Arm, Arbor Support, and Ram. Find out what milling machine parts and functions are available below.

- Column and Base:

Column and base provide supports for the other parts of a milling machine. There is an oil reservoir and pump in the column to lubricate the spindle. The column rests on the base and also it has a coolant reservoir and a pump to provide coolant in machining operations.

- Knee:

The gearing mechanism is enclosed within a knee. The knee is fastened to the column by dovetail ways. It is supported and adjusted by a vertical positioning screw also known as an elevating screw. The use of the elevating screw is to adjust the knee up and down by raising or lowering the lever with the help of hand or power feed.

- Saddle and Swivel Table:

The saddle is on the knee and supports the table. Saddle slides on horizontal dovetail on the knee and dovetail are parallel to the axis of the spindle (in horizontal milling m/c). Swivel table is attached to the saddle that swiveled (revolved) horizontally in both directions.

- Power Feed Mechanism:

The power feed mechanism is in the knee. The power feed mechanism is used to control in longitudinal (left and right), transverse (in and out), and vertical (up and down) feeds. For the desired rate of feed on the machine, the feed selection lever is placed to indicate on the feed selection plates. For some universal knee and column milling machines, feed is obtained by turning the speed selection handle till the required rate of feed is shown on feed dial. Almost in every milling machine, there is a rapid traverse lever which is used when a temporary increase in the speed of the longitudinal, transverse, or vertical feeds is required. This lever is used when the operator is aligning or positioning the work.

- Table:

A table is a rectangular casting that is presented on the top of a saddle. The table is used to hold the work or for work holding devices. There are several T-slots to hold work and work holding devices (jigs and fixtures). It can be operated by hand or by power. For moving the table by hand, it engages and turns the longitudinal hand crank. For moving it by power, it engages longitudinal direction feeds control lever.

- Spindle:

The spindle is used to hold and drive the cutting tools of a milling machine. It is mounted on the bearings and has the support of the column. The spindle is driven by an electric motor via gear trains and gear trains are on the column. The spindle face lies near the table and has an internal taper machined on it. There are two keys at the front face provide a positive drive for cutter holder or arbor.

- Over Arm/ Overhanging Arm:

Overarm is a horizontal beam and it is on the top face of the column. It may be a single casting and slides on the dovetail way which is on the top face of the column.

- Arbor Support:

Arbor support is casting with a bearing that supports the outer end of a arbor. It also helps to align the outer end of the arbor with the spindle. Arbor support prevents the springing of the outer end of arbor in cutting operations. Generally, there are two types of arbor supports used in the milling machines. The first one has a small diameter bearing hole of a maximum diameter of 1 inch. The second one has a large diameter bearing hole of up to 23/4 inch.

- Ram:

The ram is an overhanging arm in a vertical milling machine. The one end of the ram is mounted on the top of the column and the milling head is attached to another.

Accessories for Milling Machines

Common milling machine accessories include vertical milling attachments, swivel attachments, high-speed milling attachments, slotting attachments, universal dividing heads (indexing heads), circular milling attachments, rack milling attachments, vices, and arbors.

.png)