As global carbon emission regulations become increasingly stringent, the manufacturing industry is facing growing pressure to reduce its carbon footprint. Due to their long operating hours and high energy consumption, machine tools have become a critical focus in carbon management. This article highlights that by choosing high-efficiency machine tools, optimizing machining processes, and implementing intelligent systems, manufacturers can significantly cut energy use and carbon emissions—while also boosting productivity and operational stability. Green efficiency is no longer just an option; it's a necessary path for manufacturing to achieve sustainability and stay competitive.

Manufacturing Under Carbon Footprint Pressure: Why Are Machine Tools in the Spotlight?

In recent years, global regulations on carbon emissions have grown increasingly strict. ESG sustainability reporting, the Carbon Border Adjustment Mechanism (CBAM), and corporate carbon footprint audits are placing the manufacturing sector under a much tighter carbon management framework. Take the EU’s CBAM, for example—its clear purpose is to offset the cost disadvantage of imported goods with higher carbon emissions and to prevent companies from relocating high-emission production processes overseas to dodge regulations, a phenomenon known as “carbon leakage.”

In other words, manufacturers at the tail end of the supply chain are now facing dual pressures—from global markets and from policy mandates—and must respond proactively to the challenge of decarbonization. Manufacturing is already one of the largest consumers of energy, and its core equipment—such as milling machines, lathes, and grinders—are typically high-powered machines that run for extended periods, making them major contributors to a factory’s carbon emissions. When machines are inefficient, production slows, and more electricity and carbon quota are consumed per part produced.

As the responsibility for reducing emissions extends from government policies down to every link in the supply chain, the energy efficiency of machinery has naturally become a central concern for manufacturers.

Key Features of High-Efficiency Machine Tools: It's Not Just About Speed

When it comes to high-efficiency machine tools, it’s not just about how fast the spindle turns. What truly matters is how the machine performs in terms of energy usage across the entire machining process. The following key design features are essential indicators of whether a machine tool delivers true “green performance”:

- Improved Machining Efficiency: Faster Processing Means Lower Energy Use

The speed of machining and the chosen processing strategy directly affect overall energy consumption. Technologies such as high-speed cutting, heavy-duty cutting tools, or multi-axis one-pass machining (like mill-turn machines) can significantly reduce the time required to produce a single part, thereby lowering energy use per unit. For example, a five-axis mill-turn center can complete multi-face milling in one setup, minimizing tool changes and re-alignments, which boosts output per piece while reducing power consumption.

- Energy-Saving Electrical and Drive Systems

High-efficiency motors (such as IE3 or IE4 rated) and regenerative servo systems are key to energy-efficient machine tools. These systems can recover kinetic energy during deceleration or stops and feed it back into the power grid, avoiding costly power surges. In addition, precise control algorithms can dynamically adjust power output based on varying loads, effectively minimizing unnecessary energy waste.

- Energy Management During Idle Time

Machine tools continue to consume energy even while idle or on standby—an often-overlooked source of energy loss. Activating automatic shutdown or energy-saving modes during non-operating hours can significantly reduce “hidden” energy consumption. Modern CNC systems are typically equipped with idle detection and auto-sleep features that switch the machine into low-power mode after extended inactivity. From a factory management perspective, encouraging end-of-shift shutdowns is a simple yet practical energy-saving habit.

- Intelligent Cooling and Lubrication Systems

Traditional coolant pumps often run continuously, leading to excessive energy waste. In contrast, systems using variable-frequency pumps or smart start-stop controls only operate when cooling is needed, resulting in substantial energy savings. Additionally, Minimum Quantity Lubrication (MQL) technology is gaining popularity—it effectively cools while minimizing oil usage and transportation costs, offering a performance- and eco-friendly solution.

- Optimized Structural Design: Lightweight and Low Friction

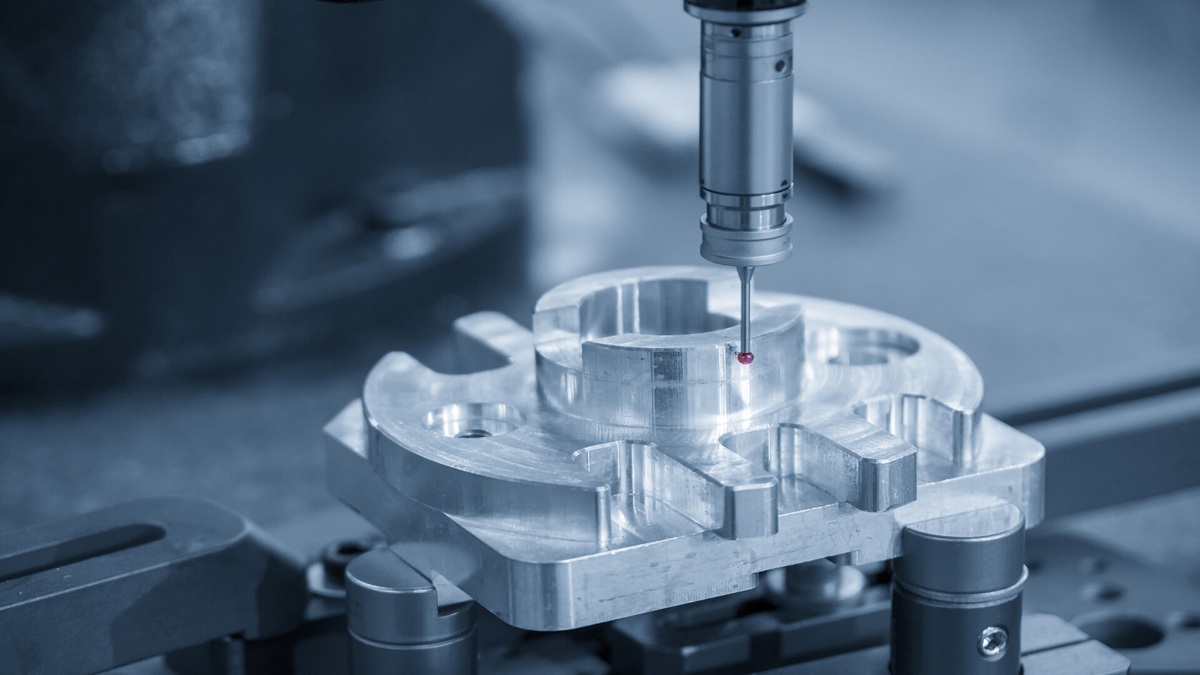

Lightweight machine structures and reduced friction or vibration also contribute to better energy efficiency. Using high-rigidity, low-mass components for the machine bed and moving parts lowers the power needed for movement and improves operational efficiency. Furthermore, vibration-damping designs shorten stabilization time during machining and reduce extra energy consumption caused by instability. New materials such as high-strength aluminum alloys and carbon fiber are increasingly used in critical components to boost both energy efficiency and operational stability.

- Digitally Optimized Machining Strategies and Cutting Tools

High-efficiency machines often work in tandem with smart manufacturing solutions. Using CAM software for toolpath simulation and strategy optimization not only improves machining accuracy but also reduces energy waste. These systems can simulate how different cutting parameters affect energy consumption, helping to minimize idle motion and rework. Additionally, using high-performance tools—such as coated blades or tungsten carbide inserts—combined with the right feed rate and cutting depth ensures energy is focused on effective cutting paths, thereby reducing the power required for each operation.

Smart Moves for a Greener Shop: Choosing the Right Machines and Strategies to Cut Carbon

In an industry environment where carbon reduction pressures are mounting, manufacturing companies can take action in two key areas: machine selection and process optimization. In fact, rather than pouring large amounts of capital into brand-new equipment, a more practical and cost-effective approach is often to integrate existing machinery with smart strategies for upgrades and optimization—achieving greater energy savings with less effort.

- Choosing the Right Machine Is Better Than Buying a New One

While purchasing new equipment can improve overall performance, the high cost and long lead time of implementation can’t be ignored. In many cases, evaluating the efficiency of existing machines—or upgrading key components, such as installing high-efficiency motors or high-speed spindles—can deliver significant energy savings.

The key lies in targeted improvements. For example, if a lightly loaded task is run on a high-end 5-axis machine that sits idle for long periods, it wastes energy without fully utilizing the equipment's capabilities. Rather than replacing everything, focusing on bottleneck processes can more effectively control both resource and energy consumption.

- Multi-Tasking Machines Outperform Traditional Multi-Machine Operations

Multi-tasking machines—such as mill-turn centers or 5-axis machining centers—combine multiple machining capabilities into one machine, enabling operations like multi-face milling, boring, and precision turning in a single setup.

Compared to traditional segmented workflows across multiple machines, multi-tasking reduces the need for repeated part transfers, re-clamping, and re-alignment. This eliminates much of the “invisible waste” and shortens production cycles, reduces error margins, and improves overall efficiency—all of which help lower the average power consumption per unit produced.

- Tool Monitoring Systems Enhance Stability and Resource Efficiency

Implementing smart tool monitoring systems—using vibration sensors, machine vision, or similar technologies—allows real-time tracking of tool wear and breakage. These systems can trigger alerts or automatically shut down machines before defects occur, significantly reducing scrap rates and the need for rework.

This leads not only to greater process stability, but also to lower energy and material waste—supporting a more accurate and reliable manufacturing process.

- Optimizing Toolpaths and Cutting Parameters

Using advanced CAM software to optimize toolpaths and feed parameters helps reduce unnecessary movements and idle cuts. From an energy-saving perspective, this “shortest path, most machining” strategy is critical.

According to industry research, simply optimizing toolpaths and programs can cut energy consumption by up to 15%. When combined with ideal cutting speeds and depths, energy savings can reach 10–20% more.

- Leveraging IoT and MES for Smarter Energy Management

By adopting Industrial IoT and Manufacturing Execution Systems (MES), companies can gain real-time visibility into power usage and operating efficiency across every machine. This data enables managers to quickly identify underperforming equipment and spot energy waste during non-productive periods.

Going a step further, predictive maintenance strategies help detect early signs of wear or potential failure, reducing unexpected downtime and preventing energy and material waste from production interruptions.

The adoption of smart manufacturing makes energy saving not just a passive response, but a proactive, trackable, and continuously improvable part of daily operations.

How High-Efficiency Machine Tools Drive Carbon Reduction

To illustrate the real-world energy and carbon-saving benefits of high-efficiency machine tools, consider the following simulated case:

A mid-sized metal parts manufacturer originally relied on several aging 3-axis CNC mill-turn machines for production, with an average machining time of 8 hours per part. The company later introduced an advanced 5-axis multi-tasking machining center, which allowed for one-time clamping to complete milling, boring, and other processes that previously required multiple setups. This significantly streamlined the workflow.

The results were clear: per-part machining time dropped to around 5.5 hours, representing a 31% increase in processing efficiency. In addition, the high-performance machine was capable of running long hours autonomously, reducing dependence on manual labor. Even more notable were the improvements in energy consumption:

Assuming the old machines consumed 6 kWh per hour, and the new machine uses 5 kWh during high-speed cutting and just 2 kWh during idle or slow movements, the impact is substantial. Based on 24-hour continuous operation and an annual output of 10,000 units, the total yearly electricity usage dropped from approximately 144,000 kWh to 100,000 kWh, saving around 44,000 kWh annually.

With Taiwan’s estimated carbon emission factor of 0.6 kg CO₂ per kWh, this upgrade equates to an annual reduction of over 26 metric tons of CO₂ emissions.

If the system is further integrated with a Manufacturing Execution System (MES) for real-time monitoring of machine energy consumption—both during production and idle times—and for optimizing production schedules and resource allocation, industry experience suggests an additional 10% or more improvement in energy efficiency can be achieved, expanding the energy-saving potential even further.

Of course, actual results may vary depending on equipment configuration, utilization rates, and workpiece characteristics. However, even under simulated conditions, this case clearly demonstrates the long-term sustainability and carbon reduction benefits of high-efficiency machine tools—making them a valuable reference point for manufacturers developing upgrade plans and carbon management strategies.

High-Efficiency Machines: The Backbone of Sustainable Manufacturing

Sustainability is no longer a trendy slogan—it's a core metric of competitiveness in the manufacturing industry amid growing global warming and carbon emissions pressures.

As key equipment on the production line, machine tools play a decisive role in determining energy consumption and carbon emissions.

When planning equipment investments and production layouts, manufacturers must prioritize green performance as a critical decision-making factor

Choosing high-efficiency machines and optimizing machining processes may require higher upfront capital investment, but in the long run, they significantly reduce energy costs and carbon footprints—creating a win-win for both business and the environment.

With carbon fees and emission trading systems becoming increasingly mature, manufacturers should proactively assess their equipment configurations and production strategies, embedding sustainability into daily operations and transforming it into a true competitive edge.

A high-efficiency machine tool is more than just a technological upgrade—it’s a concrete commitment to the future and to the environment.

Green efficiency is no longer optional—it’s the only way forward for the next phase of industrial competitiveness.

.jpg)