As the construction and interior decoration industries advance toward greater precision and customization, indoor flooring materials have become increasingly diverse and sophisticated, including solid wood, laminate flooring, stone, and high-end plastic flooring. These materials have significantly heightened protection requirements during construction. Frequent foot traffic on-site, along with the transportation of tools and materials, can easily cause scratches, dents, or surface contamination. Moreover, splashes of paint, adhesives, and other chemicals may result in irreversible damage. Without timely and effective protective measures, the final quality of the project may be compromised, leading to increased repair and replacement costs. Therefore, developing floor protection materials that combine strong protective performance with ease of installation has become a critical challenge for the industry to address.

Photo by https://www.yieashang.com.tw/index.html

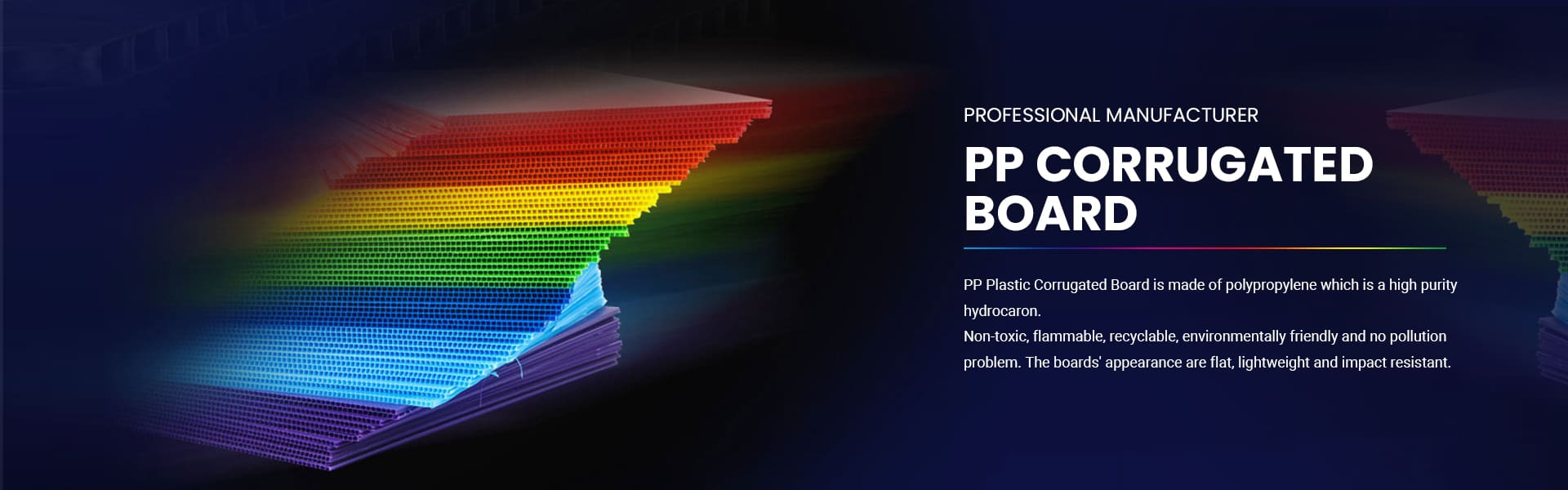

Corrugated Plastic Floor Protection Sheets

Corrugated plastic floor protection sheets are made from polypropylene (PP), a high-molecular polymer characterized by long and regular molecular chains. This structure provides excellent toughness and impact resistance, allowing the sheets to effectively withstand heavy pressure and frequent abrasion during construction. The corrugated (wavy) design not only enhances the rigidity of the panels—preventing fractures caused by excessive localized stress—but also reduces overall weight, making it easier for workers to carry and install. Additionally, this structure helps absorb external impact energy, further improving protective performance. The inherent chemical resistance of PP enables the sheets to effectively resist corrosion from substances such as cement slurry, paint, and solvents, thereby extending product lifespan. Its good flexibility also ensures that the material remains intact and resistant to damage even when used in narrow or curved environments.

Guardians of the Perfect Flooring

Plastic floor protection boards feature a smooth and dense surface that closely adheres to the flooring, forming a complete protective barrier. This effectively blocks moisture, dust, and contaminants from penetrating the floor surface, preventing swelling from dampness and damage from dirt. Additionally, these protection boards are lightweight and can be easily cut to size, allowing flexible installation tailored to the specific needs of the construction site. Their reusable nature helps reduce waste from disposable materials, aligning with modern construction’s emphasis on environmental sustainability and resource recycling. The ease of quick installation and removal further shortens preparation and cleanup times, enhancing overall operational efficiency.

UV Resistance and Weather Durability

In addition to widespread use in indoor construction sites, corrugated plastic floor protection sheets are also commonly applied in outdoor or semi-open environments, such as building exterior wall renovations, outdoor exhibitions, and temporary construction site pathways. In these settings, prolonged exposure to direct sunlight can cause plastic materials—if not specially treated—to age prematurely due to ultraviolet (UV) radiation, resulting in brittleness, discoloration, and even cracking, which severely impact the product’s lifespan and protective performance.

To enhance weather resistance, manufacturers typically incorporate UV stabilizers into the polypropylene (PP) base material. These additives effectively absorb or scatter ultraviolet rays, reducing the UV energy that damages the plastic’s molecular chain structure. Common UV additives include:

- UV Absorbers: Absorb UV energy and convert it into heat, preventing direct UV damage to the plastic material.

- Hindered Amine Light Stabilizers (HALS): Capture free radicals to delay polymer chain breakage, improving the material’s light stability.

- Antioxidants: Used in conjunction with UV additives to slow down oxidation reactions triggered by UV exposure.

Formulations and concentrations of these additives are adjusted according to different usage environments and requirements, ensuring that corrugated plastic floor protection sheets maintain excellent physical properties and stable appearance even under intense sunlight exposure.

Challenges and Opportunities for Protective Materials in the Era of Refinement

As construction techniques continue to advance, clients’ demands for finishing quality and on-site safety are steadily increasing, driving higher performance requirements for floor protection materials. Looking ahead, corrugated plastic floor protection sheets are expected to evolve toward greater strength, lighter weight, and environmentally friendly materials. Additionally, integration with smart labeling and modular design will enhance ease of construction monitoring and management.

urthermore, with the growing emphasis on green building and circular economy principles, recyclable and durable plastic protection boards will become standard, assisting builders in achieving sustainable development goals. Under this trend, corrugated plastic floor protection sheets will not only serve as protective tools but also play a vital role in improving construction quality and efficiency, reducing costs, and minimizing environmental impact.

.jpg)

.png)